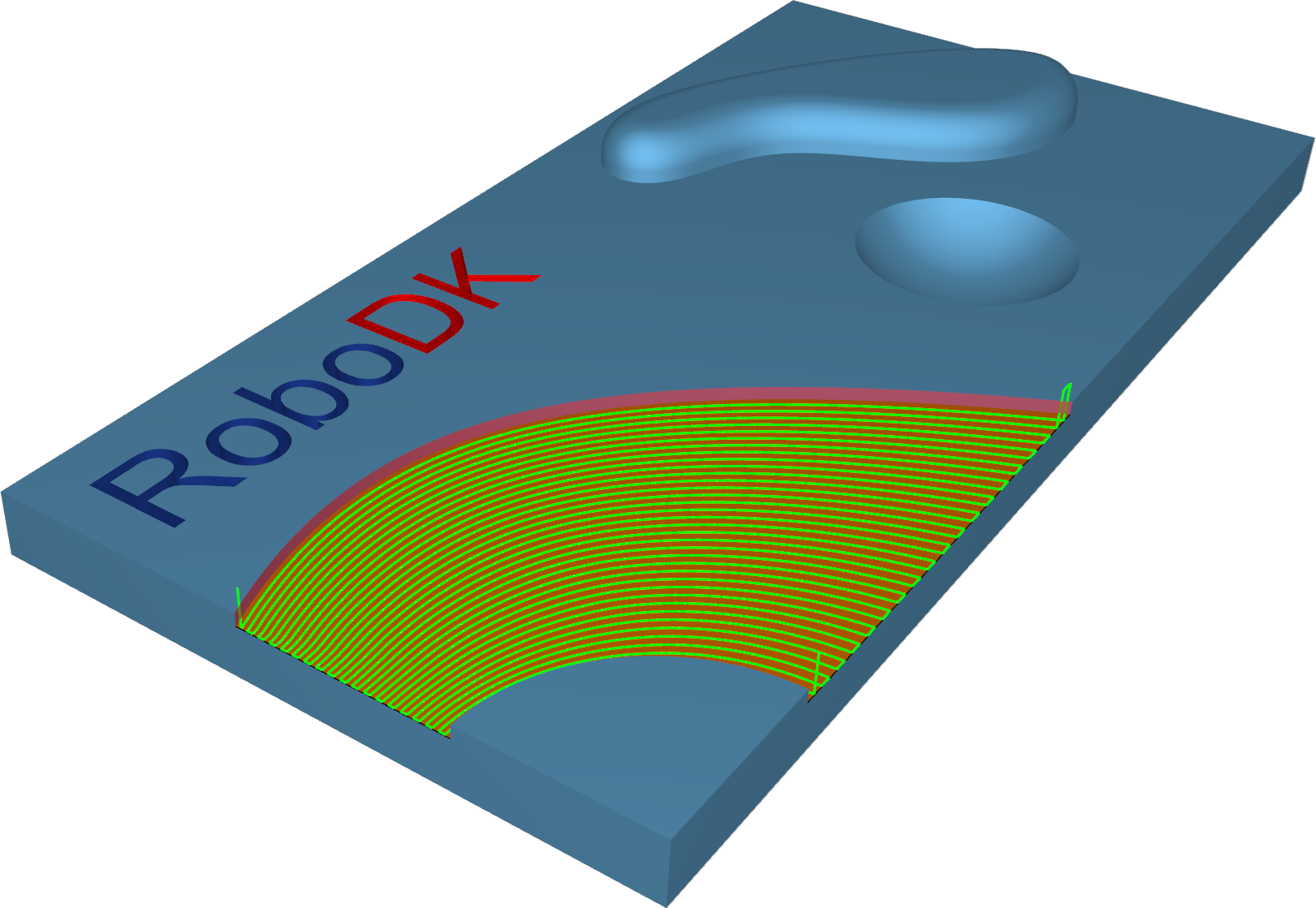

Surfaces–Morph between two surfaces

This option will create a morph toolpath on the drive surface. The drive surface is enclosed by two check surfaces. Morph means that the generated toolpath is approximated between the check surfaces and evenly spread over the drive surface. Especially the impeller machining with its twisted turbine blades can be machined using this option.

Bi-Tangency - the main advantage is the possibility to compensate the tool to the drive surface and check the surface in the left and right corner of the work piece. All you need to do is to enable the tool radius from (margin) options, which is the distance between the tool center and the surfaces.

Station: CAM-Surfaces-MorphBetween2Surfaces.

Video: https://youtu.be/5KfPuzAIxQA.