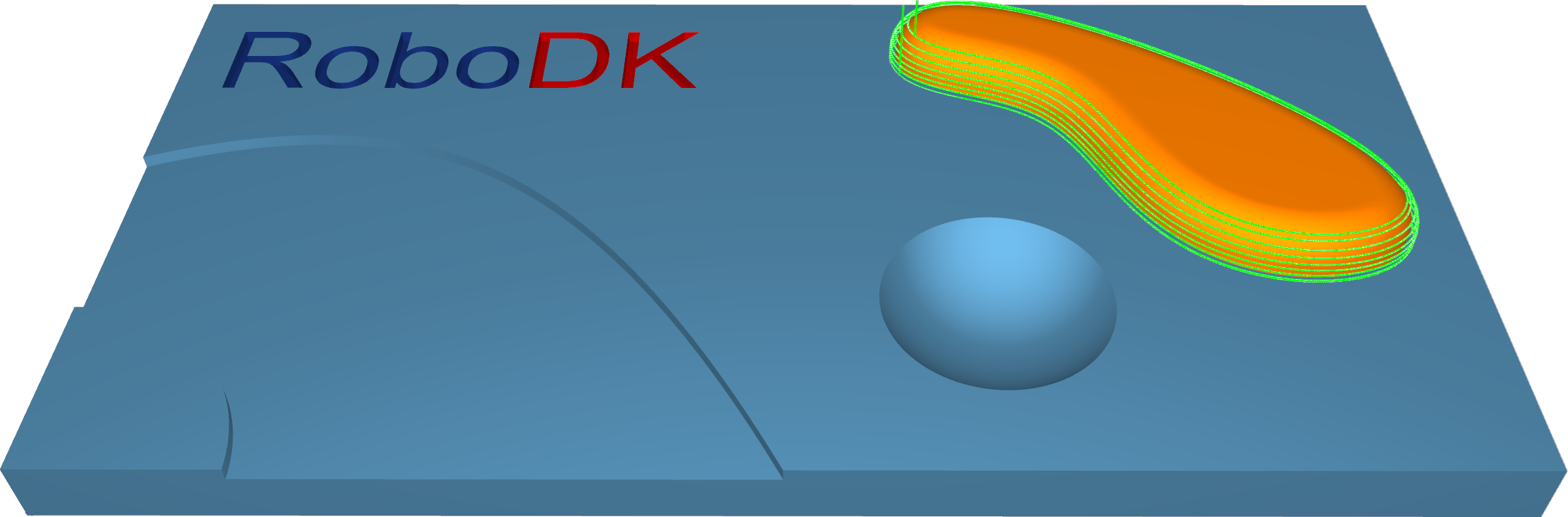

Trimesh–Constant Z

This strategy allows the machining of 3d components with toolpath passes that are parallel to a plane that depends on the machining direction. Imagine a component being sliced from top to bottom.

This strategy is generally used to semi-finish or finish a component. It is best suited to machine steep areas - vertical or near vertical walls of a 3d component.

1.Constant Z + Constant Cusp: This pattern enables you to machine parts consisting of steep and shallow regions in one iteration. Steep regions are machined with the help of Constant Z slices. A constant cusp is applied for shallow area processing.

2.Constant Z + Parallel Cuts: This pattern makes it possible to machine parts consisting of steep and shallow regions in one iteration. Steep regions are machined with the help of Constant Z slices. Parallel cuts are applied for shallow area processing.

Station: CAM-Trimesh-ConstantZ.