6. Examples¶

This section shows some examples in Python that use the RoboDK API. Most of these examples can be easily ported to other programming languages (such as C#, C++, .Net or Matlab). These examples were tested using Python 3 and might require some adjustments to work on Python 2.

Additional RoboDK API examples are included in the following folders:

C:/RoboDK/Library/Scripts/

C:/RoboDK/Library/Macros/

Any Python files available in the Scripts folder can be run as a standalone script by selecting:

Tools-Run Script

Select the script to run it

Many RoboDK Add-ins have been created using Python and they are not compiled so you can also use them as examples: https://robodk.com/addins.

Some examples are used in sample RoboDK projects (RDK files) provided in the RoboDK library. Some examples are also available on GitHub: https://github.com/RoboDK/RoboDK-API/tree/master/Python/Examples.

6.1. Offline Programming¶

This example shows how to generate a hexagonal path given one target. This macro draws a polygon of radius R and n_sides vertices using the RoboDK API for Python.

- More information here:

Offline Programming with RoboDK: https://robodk.com/offline-programming

Simulation using the RoboDK API for Python: https://robodk.com/doc/en/RoboDK-API.html#PythonAPIOLP

Post processors: https://robodk.com/doc/en/Post-Processors.html#PostProcessor

Offline programming overview: https://www.youtube.com/watch?list=PLjiA6TvRACQc5E_3c5f3TFXEa56XNR1-m&v=Ic-iKGSc7dk

# This macro shows an example to draw a polygon of radius R and n_sides vertices using the RoboDK API for Python

# More information about the RoboDK API here:

# https://robodk.com/doc/en/RoboDK-API.html

from robodk.robolink import * # API to communicate with RoboDK

from robodk.robomath import * # basic matrix operations

# Any interaction with RoboDK must be done through RDK:

RDK = Robolink()

# Select a robot (popup is displayed if more than one robot is available)

robot = RDK.ItemUserPick('Select a robot', ITEM_TYPE_ROBOT)

if not robot.Valid():

raise Exception('No robot selected or available')

# get the current position of the TCP with respect to the reference frame:

# (4x4 matrix representing position and orientation)

target_ref = robot.Pose()

pos_ref = target_ref.Pos()

print("Drawing a polygon around the target: ")

print(Pose_2_TxyzRxyz(target_ref))

# move the robot to the first point:

robot.MoveJ(target_ref)

# It is important to provide the reference frame and the tool frames when generating programs offline

robot.setPoseFrame(robot.PoseFrame())

robot.setPoseTool(robot.PoseTool())

robot.setRounding(10) # Set the rounding parameter (Also known as: CNT, APO/C_DIS, ZoneData, Blending radius, cornering, ...)

robot.setSpeed(200) # Set linear speed in mm/s

# Set the number of sides of the polygon:

n_sides = 6

R = 100

# make a hexagon around reference target:

for i in range(n_sides + 1):

ang = i * 2 * pi / n_sides #angle: 0, 60, 120, ...

#-----------------------------

# Movement relative to the reference frame

# Create a copy of the target

target_i = Mat(target_ref)

pos_i = target_i.Pos()

pos_i[0] = pos_i[0] + R * cos(ang)

pos_i[1] = pos_i[1] + R * sin(ang)

target_i.setPos(pos_i)

print("Moving to target %i: angle %.1f" % (i, ang * 180 / pi))

print(str(Pose_2_TxyzRxyz(target_i)))

robot.MoveL(target_i)

#-----------------------------

# Post multiply: relative to the tool

#target_i = target_ref * rotz(ang) * transl(R,0,0) * rotz(-ang)

#robot.MoveL(target_i)

# move back to the center, then home:

robot.MoveL(target_ref)

print('Done')

6.2. Offline Programming (GUI)¶

This example is an improved version of the previous example. It prompts the user for some input before simulating or generating a program. This example shows how RoboDK and the Python GUI tkinter can display graphical user interface to customize program generation according to certain parameters.

- More information here:

Simulation using the RoboDK API for Python: https://robodk.com/doc/en/RoboDK-API.html#PythonAPIOLP

Post processors: https://robodk.com/doc/en/Post-Processors.html#PostProcessor

# This example shows how RoboDK and the Python GUI tkinter can display graphical user interface to customize program generation according to certain parameters

# This example is an improvement of the weld Hexagon

# More information about the RoboDK API here:

# https://robodk.com/doc/en/RoboDK-API.html

from robodk.robolink import * # API to communicate with RoboDK

from robodk.robomath import * # robodk robotics toolbox

# Set up default parameters

PROGRAM_NAME = "DoWeld" # Name of the program

APPROACH = 300 # Approach distance

RADIUS = 200 # Radius of the polygon

SPEED_WELD = 50 # Speed in mn/s of the welding path

SPEED_MOVE = 200 # Speed in mm/s of the approach/retract movements

SIDES = 8 # Number of sides for the polygon

DRY_RUN = 1 # If 0, it will generate SprayOn/SprayOff program calls, otherwise it will not activate the tool

RUN_MODE = RUNMODE_SIMULATE # Simulation behavior (simulate, generate program or generate the program and send it to the robot)

# use RUNMODE_SIMULATE to simulate only

# use RUNMODE_MAKE_ROBOTPROG to generate the program

# use RUNMODE_MAKE_ROBOTPROG_AND_UPLOAD to generate the program and send it to the robot

# Main program

def RunProgram():

# Use default global variables

global PROGRAM_NAME

global APPROACH

global RADIUS

global SPEED_WELD

global SPEED_MOVE

global SIDES

global DRY_RUN

global RUN_MODE

# Any interaction with RoboDK must be done through RDK:

RDK = Robolink()

# get the home target and the welding targets:

home = RDK.Item('Home')

target = RDK.Item('Target Reference')

# get the robot as an item:

robot = RDK.Item('', ITEM_TYPE_ROBOT)

# impose the run mode

RDK.setRunMode(RUN_MODE)

# set the name of the generated program

RDK.ProgramStart(PROGRAM_NAME, "", "", robot)

# get the pose of the reference target (4x4 matrix representing position and orientation):

poseref = target.Pose()

# move the robot to home, then to an approach position

robot.MoveJ(home)

robot.setSpeed(SPEED_MOVE)

robot.MoveJ(transl(0, 0, APPROACH) * poseref)

# make an polygon of n SIDES around the reference target

for i in range(SIDES + 1):

ang = i * 2 * pi / SIDES #angle: 0, 60, 120, ...

# Calculate next position

posei = poseref * rotz(ang) * transl(RADIUS, 0, 0) * rotz(-ang)

robot.MoveL(posei)

# Impose weld speed only for the first point

if i == 0:

# Set weld speed and activate the gun after reaching the first point

robot.setSpeed(SPEED_WELD)

if not DRY_RUN:

# Activate the spray right after we reached the first point

robot.RunCodeCustom("SprayOn", INSTRUCTION_CALL_PROGRAM)

# Stop the tool if we are not doing a dry run

if not DRY_RUN:

robot.RunCodeCustom("SprayOff", INSTRUCTION_CALL_PROGRAM)

robot.setSpeed(SPEED_MOVE)

# move back to the approach point, then home:

robot.MoveL(transl(0, 0, APPROACH) * poseref)

robot.MoveJ(home)

# Provoke program generation (automatic when RDK is finished)

RDK.Finish()

# Use tkinter to display GUI menus

from tkinter import *

# Generate the main window

root = Tk()

root.title("Program settings")

# Use variables linked to the global variables

runmode = IntVar()

runmode.set(RUN_MODE) # setting up default value

dryrun = IntVar()

dryrun.set(DRY_RUN) # setting up default value

entry_name = StringVar()

entry_name.set(PROGRAM_NAME)

entry_speed = StringVar()

entry_speed.set(str(SPEED_WELD))

# Define feedback call

def ShowRunMode():

print("Selected run mode: " + str(runmode.get()))

# Define a label and entry text for the program name

Label(root, text="Program name").pack()

Entry(root, textvariable=entry_name).pack()

# Define a label and entry text for the weld speed

Label(root, text="Weld speed (mm/s)").pack()

Entry(root, textvariable=entry_speed).pack()

# Define a check box to do a dry run

Checkbutton(root, text="Dry run", variable=dryrun, onvalue=1, offvalue=0, height=5, width=20).pack()

# Add a display label for the run mode

Label(root, text="Run mode", justify=LEFT, padx=20).pack()

# Set up the run modes (radio buttons)

runmodes = [("Simulate", RUNMODE_SIMULATE), ("Generate program", RUNMODE_MAKE_ROBOTPROG), ("Send program to robot", RUNMODE_MAKE_ROBOTPROG_AND_START)]

for txt, val in runmodes:

Radiobutton(root, text=txt, padx=20, variable=runmode, command=ShowRunMode, value=val).pack(anchor=W)

# Add a button and default action to execute the current choice of the user

def ExecuteChoice():

global DRY_RUN

global RUN_MODE

global SPEED_WELD

global PROGRAM_NAME

DRY_RUN = dryrun.get()

RUN_MODE = runmode.get()

SPEED_WELD = float(entry_speed.get())

PROGRAM_NAME = entry_name.get()

# Run the main program once all the global variables have been set

RunProgram()

Button(root, text='Simulate/Generate', command=ExecuteChoice).pack()

# Important to display the graphical user interface

root.mainloop()

6.3. Online Programming¶

This example is a modified version of the previous two examples which supports running the program on the robot directly from the script. This example will run a Python program on the robot from the Python API (online programming). If a robot is connected to the PC, the simulation and the real robot will move at the same time as the Python program is executed. The same program can also be used for simulation or offline programming.

- More information here:

Online programming using the RoboDK API for Python: https://robodk.com/doc/en/RoboDK-API.html#PythonAPIOnline

Robot drivers: https://robodk.com/doc/en/Robot-Drivers.html#RobotDrivers

# This macro shows an example to run a program on the robot from the Python API (online programming)

#

# Important: By default, right clicking a program on the RoboDK API and selecting "Run On Robot" has the same effect as running this example.

# Use the Example_OnlineProgramming.py instead if the program is run from the RoboDK Station Tree

#

# This example forces the connection to the robot by using:

# robot.Connect()

# and

# RDK.setRunMode(RUNMODE_RUN_ROBOT)

# In this script, if the variable RUN_ON_ROBOT is set to True, an attempt will be made to connect to the robot

# Alternatively, if the RUN_ON_ROBOT variable is set to False, the program will be simulated (offline programming)

#

# More information about the RoboDK API here:

# https://robodk.com/doc/en/RoboDK-API.html

from robodk.robolink import * # API to communicate with RoboDK

from robodk.robomath import * # basic matrix operations

# Any interaction with RoboDK must be done through RDK:

RDK = Robolink()

# Select a robot (popup is displayed if more than one robot is available)

robot = RDK.ItemUserPick('Select a robot', ITEM_TYPE_ROBOT)

if not robot.Valid():

raise Exception('No robot selected or available')

RUN_ON_ROBOT = True

# Important: by default, the run mode is RUNMODE_SIMULATE

# If the program is generated offline manually the runmode will be RUNMODE_MAKE_ROBOTPROG,

# Therefore, we should not run the program on the robot

if RDK.RunMode() != RUNMODE_SIMULATE:

RUN_ON_ROBOT = False

if RUN_ON_ROBOT:

# Update connection parameters if required:

# robot.setConnectionParams('192.168.2.35',30000,'/', 'anonymous','')

# Connect to the robot using default IP

success = robot.Connect() # Try to connect once

#success robot.ConnectSafe() # Try to connect multiple times

status, status_msg = robot.ConnectedState()

if status != ROBOTCOM_READY:

# Stop if the connection did not succeed

print(status_msg)

raise Exception("Failed to connect: " + status_msg)

# This will set to run the API programs on the robot and the simulator (online programming)

RDK.setRunMode(RUNMODE_RUN_ROBOT)

# Note: This is set automatically when we Connect() to the robot through the API

#else:

# This will run the API program on the simulator (offline programming)

# RDK.setRunMode(RUNMODE_SIMULATE)

# Note: This is the default setting if we do not execute robot.Connect()

# We should not set the RUNMODE_SIMULATE if we want to be able to generate the robot programm offline

# Get the current joint position of the robot

# (updates the position on the robot simulator)

joints_ref = robot.Joints()

# get the current position of the TCP with respect to the reference frame:

# (4x4 matrix representing position and orientation)

target_ref = robot.Pose()

pos_ref = target_ref.Pos()

print("Drawing a polygon around the target: ")

print(Pose_2_TxyzRxyz(target_ref))

# move the robot to the first point:

robot.MoveJ(target_ref)

# It is important to provide the reference frame and the tool frames when generating programs offline

# It is important to update the TCP on the robot mostly when using the driver

robot.setPoseFrame(robot.PoseFrame())

robot.setPoseTool(robot.PoseTool())

robot.setRounding(10) # Set the rounding parameter (Also known as: CNT, APO/C_DIS, ZoneData, Blending radius, cornering, ...)

robot.setSpeed(200) # Set linear speed in mm/s

# Set the number of sides of the polygon:

n_sides = 6

R = 100

# make a hexagon around reference target:

for i in range(n_sides + 1):

ang = i * 2 * pi / n_sides #angle: 0, 60, 120, ...

#-----------------------------

# Movement relative to the reference frame

# Create a copy of the target

target_i = Mat(target_ref)

pos_i = target_i.Pos()

pos_i[0] = pos_i[0] + R * cos(ang)

pos_i[1] = pos_i[1] + R * sin(ang)

target_i.setPos(pos_i)

print("Moving to target %i: angle %.1f" % (i, ang * 180 / pi))

print(str(Pose_2_TxyzRxyz(target_i)))

robot.MoveL(target_i)

#-----------------------------

# Post multiply: relative to the tool

#target_i = target_ref * rotz(ang) * transl(R,0,0) * rotz(-ang)

#robot.MoveL(target_i)

# move back to the center, then home:

robot.MoveL(target_ref)

print('Done')

## Example to run a program created using the GUI from the API

#prog = RDK.Item('MainProgram', ITEM_TYPE_PROGRAM)

## prog.setRunType(PROGRAM_RUN_ON_ROBOT) # Run on robot option

## prog.setRunType(PROGRAM_RUN_ON_SIMULATOR) # Run on simulator (default on startup)

#prog.RunProgram()

#while prog.Busy() == 1:

# pause(0.1)

#print("Program done")

6.4. Points to Program¶

This example shows different ways of moving a robot along a list of points.

# Move a robot along a line given a start and end point by steps

# This macro shows three different ways of programming a robot using a Python script and the RoboDK API

# More information about the RoboDK API here:

# https://robodk.com/doc/en/RoboDK-API.html

# For more information visit:

# https://robodk.com/doc/en/PythonAPI/robodk.html#robolink-py

# Default parameters:

P_START = [1755, -500, 2155] # Start point with respect to the robot base frame

P_END = [1755, 600, 2155] # End point with respect to the robot base frame

NUM_POINTS = 10 # Number of points to interpolate

# Function definition to create a list of points (line)

def MakePoints(xStart, xEnd, numPoints):

"""Generates a list of points"""

if len(xStart) != 3 or len(xEnd) != 3:

raise Exception("Start and end point must be 3-dimensional vectors")

if numPoints < 2:

raise Exception("At least two points are required")

# Starting Points

pt_list = []

x = xStart[0]

y = xStart[1]

z = xStart[2]

# How much we add/subtract between each interpolated point

x_steps = (xEnd[0] - xStart[0]) / (numPoints - 1)

y_steps = (xEnd[1] - xStart[1]) / (numPoints - 1)

z_steps = (xEnd[2] - xStart[2]) / (numPoints - 1)

# Incrementally add to each point until the end point is reached

for i in range(numPoints):

point_i = [x, y, z] # create a point

#append the point to the list

pt_list.append(point_i)

x = x + x_steps

y = y + y_steps

z = z + z_steps

return pt_list

#---------------------------------------------------

#--------------- PROGRAM START ---------------------

from robodk.robolink import * # API to communicate with RoboDK

from robodk.robomath import * # basic matrix operations

# Generate the points curve path

POINTS = MakePoints(P_START, P_END, NUM_POINTS)

# Initialize the RoboDK API

RDK = Robolink()

# turn off auto rendering (faster)

RDK.Render(False)

# Automatically delete previously generated items (Auto tag)

list_names = RDK.ItemList() # list all names

for item_name in list_names:

if item_name.startswith('Auto'):

RDK.Item(item_name).Delete()

# Promt the user to select a robot (if only one robot is available it will select that robot automatically)

robot = RDK.ItemUserPick('Select a robot', ITEM_TYPE_ROBOT)

# Turn rendering ON before starting the simulation

RDK.Render(True)

# Abort if the user hits Cancel

if not robot.Valid():

quit()

# Retrieve the robot reference frame

reference = robot.Parent()

# Use the robot base frame as the active reference

robot.setPoseFrame(reference)

# get the current orientation of the robot (with respect to the active reference frame and tool frame)

pose_ref = robot.Pose()

print(Pose_2_TxyzRxyz(pose_ref))

# a pose can also be defined as xyzwpr / xyzABC

#pose_ref = TxyzRxyz_2_Pose([100,200,300,0,0,pi])

#-------------------------------------------------------------

# Option 1: Move the robot using the Python script

# We can automatically force the "Create robot program" action using a RUNMODE state

# RDK.setRunMode(RUNMODE_MAKE_ROBOTPROG)

# Iterate through all the points

for i in range(NUM_POINTS):

# update the reference target with the desired XYZ coordinates

pose_i = pose_ref

pose_i.setPos(POINTS[i])

# Move the robot to that target:

robot.MoveJ(pose_i)

# Done, stop program execution

quit()

#-------------------------------------------------------------

# Option 2: Create the program on the graphical user interface

# Turn off rendering

RDK.Render(False)

prog = RDK.AddProgram('AutoProgram')

# Iterate through all the points

for i in range(NUM_POINTS):

# add a new target and keep the reference to it

ti = RDK.AddTarget('Auto Target %i' % (i + 1))

# use the reference pose and update the XYZ position

pose_i = pose_ref

pose_i.setPos(POINTS[i])

ti.setPose(pose_i)

# force to use the target as a Cartesian target

ti.setAsCartesianTarget()

# Optionally, add the target as a Linear/Joint move in the new program

prog.MoveL(ti)

# Turn rendering ON before starting the simulation

RDK.Render(True)

# Run the program on the simulator (simulate the program):

prog.RunProgram()

# prog.WaitFinished() # wait for the program to finish

# We can create the program automatically

# prog.MakeProgram()

# Also, if we have the robot driver we could use the following call to provoke a "Run on robot" action (simulation and the robot move simultaneously)

# prog.setRunType(PROGRAM_RUN_ON_ROBOT)

# Done, stop program execution

quit()

#-------------------------------------------------------------

# Option 3: Move the robot using the Python script and detect if movements can be linear

# This is an improved version of option 1

#

# We can automatically force the "Create robot program" action using a RUNMODE state

# RDK.setRunMode(RUNMODE_MAKE_ROBOTPROG)

# Iterate through all the points

ROBOT_JOINTS = None

for i in range(NUM_POINTS):

# update the reference target with the desired XYZ coordinates

pose_i = pose_ref

pose_i.setPos(POINTS[i])

# Move the robot to that target:

if i == 0:

# important: make the first movement a joint move!

robot.MoveJ(pose_i)

ROBOT_JOINTS = robot.Joints()

else:

# test if we can do a linear movement from the current position to the next point

if robot.MoveL_Collision(ROBOT_JOINTS, pose_i) == 0:

robot.MoveL(pose_i)

else:

robot.MoveJ(pose_i)

ROBOT_JOINTS = robot.Joints()

# Done, stop program execution

quit()

#-------------------------------------------------------------

# Option 4: Create a follow curve project

# First we need to create an object from the provided points or add the points to an existing object and optionally project them on the surface

# Create a new object given the list of points (the 3xN vector can be extended to 6xN to provide the normal)

object_points = RDK.AddPoints(POINTS)

# Alternatively, we can project the points on the object surface

# object = RDK.Item('Object', ITEM_TYPE_OBJECT)

# object_points = object.AddPoints(POINTS, PROJECTION_ALONG_NORMAL_RECALC)

# Place the points at the same location as the reference frame of the object

# object_points.setParent(object.Parent())

# Set the name of the object containing points

object_points.setName('AutoPoints n%i' % NUM_POINTS)

path_settings = RDK.AddMillingProject("AutoPointFollow settings")

prog, status = path_settings.setMillingParameters(part=object_points)

# At this point, we may have to manually adjust the tool object or the reference frame

# Run the create program if success

prog.RunProgram()

# Done

quit()

#-------------------------------------------------------------

# Option 5: Create a follow points project (similar to Option 4)

# First we need to create an object from the provided points or add the points to an existing object and optionally project them on the surface

# Create a new object given the list of points:

object_curve = RDK.AddCurve(POINTS)

# Alternatively, we can project the points on the object surface

# object = RDK.Item('Object', ITEM_TYPE_OBJECT)

# object_curve = object.AddCurve(POINTS, PROJECTION_ALONG_NORMAL_RECALC)

# Place the curve at the same location as the reference frame of the object

# object_curve.setParent(object.Parent())

# Set the name of the object containing points

object_curve.setName('AutoPoints n%i' % NUM_POINTS)

# Create a new "Curve follow project" to automatically follow the curve

path_settings = RDK.AddMillingProject("AutoCurveFollow settings")

prog, status = path_settings.setMillingParameters(part=object_curve)

# At this point, we may have to manually adjust the tool object or the reference frame

# Run the create program if success

prog.RunProgram()

# Done

quit()

#-------------------------------------------------------------

# Option 6: Move the robot using the Python script and measure using an external measurement system

# This example is meant to help validating robot accuracy through distance measurements and using a laser tracker or a stereo camera

if robot.ConnectSafe() <= 0:

raise Exception("Can't connect to robot")

RDK.setRunMode(RUNMODE_RUN_ROBOT) # It is redundant if connection worked successfully

POINTS_NOMINAL = []

POINTS_ACCURATE = []

STABILIZATION_TIME = 2 # stabilization time in seconds before taking a measurement

for i in range(NUM_POINTS):

# build a target using the reference orientation and the XYZ coordinates

pose_i = pose_ref

pose_i.setPos(LINE[i])

# Move to the target with the nomrinal kinematics

RDK.RunMessage('Moving to point %i (Nominal kinematics)' % (i + 1))

RDK.RunMessage(str(Pose_2_KUKA(pose_i)))

# Solve nominal inverse kinematics

robot.setAccuracyActive(False)

ji = robot.SolveIK(pose_i)

robot.MoveL(ji)

robot.Pause(STABILIZATION_TIME)

# Take the measurement

while True:

pose1, pose2, npoints1, npoints2, time, errors = RDK.StereoCamera_Measure()

if errors != 0 or npoints1 < 4 or npoints2 < 4:

print('Invalid measurement. Retrying in 2 seconds...')

pause(2)

else:

# calculate the pose of the tool with respect to the reference frame

measured = invH(pose1) * pose2

# retrieve XYZ value of the measurement

POINTS_NOMINAL = measured.Pos()

break

# Move to the target with the accurate kinematics

RDK.RunMessage('Moving to point %i (Accurate kinematics)' % (i + 1))

robot.setAccuracyActive(True)

ji = robot.SolveIK(pose_i)

robot.MoveL(ji)

robot.Pause(STABILIZATION_TIME)

while True:

pose1, pose2, npoints1, npoints2, time, errors = RDK.StereoCamera_Measure()

if errors != 0 or npoints1 < 4 or npoints2 < 4:

print('Invalid measurement. Retrying in 2 seconds...')

pause(2)

else:

# calculate the pose of the tool with respect to the reference frame

measured = invH(pose1) * pose2

# retrieve XYZ value of the measurement

POINTS_ACCURATE = measured.Pos()

break

# At this point we can check the accurate vs the nominal kinematics and create the following table:

print('pa\tpb\tdist\tdist nom\tdist acc\terror nom\terror acc')

for i in range(numPoints):

for j in range(numPoints + 1, numPoints):

dist_program = distance(LINE[i], LINE[j])

dist_nominal = distance(POINTS_NOMINAL[i], POINTS_NOMINAL[j])

dist_accurate = distance(POINTS_ACCURATE[i], POINTS_ACCURATE[j])

error_nominal = abs(dist_nominal - dist_program)

error_accurate = abs(dist_accurate - dist_program)

print('%i\t%i\t%.3f\t%.3f\t%.3f\t%.3f\t%.3f' % (i + 1, j + 1, dist_program, dist_nominal, dist_accurate, error_nominal, error_accurate))

quit()

6.5. Points to Curve¶

This example shows how to automatically setup a curve follow project from the API. This example achieves the same goal as the previous example in a different way by setting up a curve follow project or a point follow project.

# Type help("robolink") or help("robodk") for more information

# Press F5 to run the script

# Documentation: https://robodk.com/doc/en/RoboDK-API.html

# Reference: https://robodk.com/doc/en/PythonAPI/index.html

#

# Move a robot along a line given a start and end point by steps

# This macro shows different ways of programming a robot using a Python script and the RoboDK API

# Default parameters:

P_START = [1755, -500, 2155] # Start point with respect to the robot base frame

P_END = [1755, 600, 2155] # End point with respect to the robot base frame

NUM_POINTS = 10 # Number of points to interpolate

# Function definition to create a list of points (line)

def MakePoints(xStart, xEnd, numPoints):

"""Generates a list of points"""

if len(xStart) != 3 or len(xEnd) != 3:

raise Exception("Start and end point must be 3-dimensional vectors")

if numPoints < 2:

raise Exception("At least two points are required")

# Starting Points

pt_list = []

x = xStart[0]

y = xStart[1]

z = xStart[2]

# How much we add/subtract between each interpolated point

x_steps = (xEnd[0] - xStart[0]) / (numPoints - 1)

y_steps = (xEnd[1] - xStart[1]) / (numPoints - 1)

z_steps = (xEnd[2] - xStart[2]) / (numPoints - 1)

# Incrementally add to each point until the end point is reached

for i in range(numPoints):

point_i = [x, y, z] # create a point

#append the point to the list

pt_list.append(point_i)

x = x + x_steps

y = y + y_steps

z = z + z_steps

return pt_list

#---------------------------------------------------

#--------------- PROGRAM START ---------------------

from robodk.robolink import * # API to communicate with RoboDK for simulation and offline/online programming

from robodk.robomath import * # Robotics toolbox for industrial robots

# Generate the points curve path

POINTS = MakePoints(P_START, P_END, NUM_POINTS)

# Initialize the RoboDK API

RDK = Robolink()

# turn off auto rendering (faster)

RDK.Render(False)

# Automatically delete previously generated items (Auto tag)

list_items = RDK.ItemList() # list all names

for item in list_items:

if item.Name().startswith('Auto'):

item.Delete()

# Promt the user to select a robot (if only one robot is available it will select that robot automatically)

robot = RDK.ItemUserPick('Select a robot', ITEM_TYPE_ROBOT)

# Turn rendering ON before starting the simulation

RDK.Render(True)

# Abort if the user hits Cancel

if not robot.Valid():

quit()

# Retrieve the robot reference frame

reference = robot.Parent()

# Use the robot base frame as the active reference

robot.setPoseFrame(reference)

# get the current orientation of the robot (with respect to the active reference frame and tool frame)

pose_ref = robot.Pose()

print(Pose_2_TxyzRxyz(pose_ref))

# a pose can also be defined as xyzwpr / xyzABC

#pose_ref = TxyzRxyz_2_Pose([100,200,300,0,0,pi])

#-------------------------------------------------------------

# Option 1: Create a curve follow project

# First we need to create an object from the provided points or add the points to an existing object and optionally project them on the surface

# Create a new object given the list of points (the 3xN vector can be extended to 6xN to provide the normal)

object_points = RDK.AddPoints(POINTS)

# Alternatively, we can project the points on the object surface

# object = RDK.Item('Object', ITEM_TYPE_OBJECT)

# object_points = object.AddPoints(POINTS, PROJECTION_ALONG_NORMAL_RECALC)

# Place the points at the same location as the reference frame of the object

# object_points.setParent(object.Parent())

# Set the name of the object containing points

object_points.setName('AutoPoints n%i' % NUM_POINTS)

path_settings = RDK.AddMillingProject("AutoPointFollow settings")

prog, status = path_settings.setMillingParameters(part=object_points)

# At this point, we may have to manually adjust the tool object or the reference frame

# Run the create program if success

prog.RunProgram()

# Done

quit()

#-------------------------------------------------------------

# Option 2: Create a point follow project (similar to Option 4)

# First we need to create an object from the provided points or add the points to an existing object and optionally project them on the surface

# Create a new object given the list of points:

object_curve = RDK.AddCurve(POINTS)

# Alternatively, we can project the points on the object surface

# object = RDK.Item('Object', ITEM_TYPE_OBJECT)

# object_curve = object.AddCurve(POINTS, PROJECTION_ALONG_NORMAL_RECALC)

# Place the curve at the same location as the reference frame of the object

# object_curve.setParent(object.Parent())

# Set the name of the object containing points

object_curve.setName('AutoPoints n%i' % NUM_POINTS)

# Create a new "Curve follow project" to automatically follow the curve

path_settings = RDK.AddMillingProject("AutoCurveFollow settings")

prog, status = path_settings.setMillingParameters(part=object_curve)

# At this point, we may have to manually adjust the tool object or the reference frame

# Run the create program if success

prog.RunProgram()

# Done

quit()

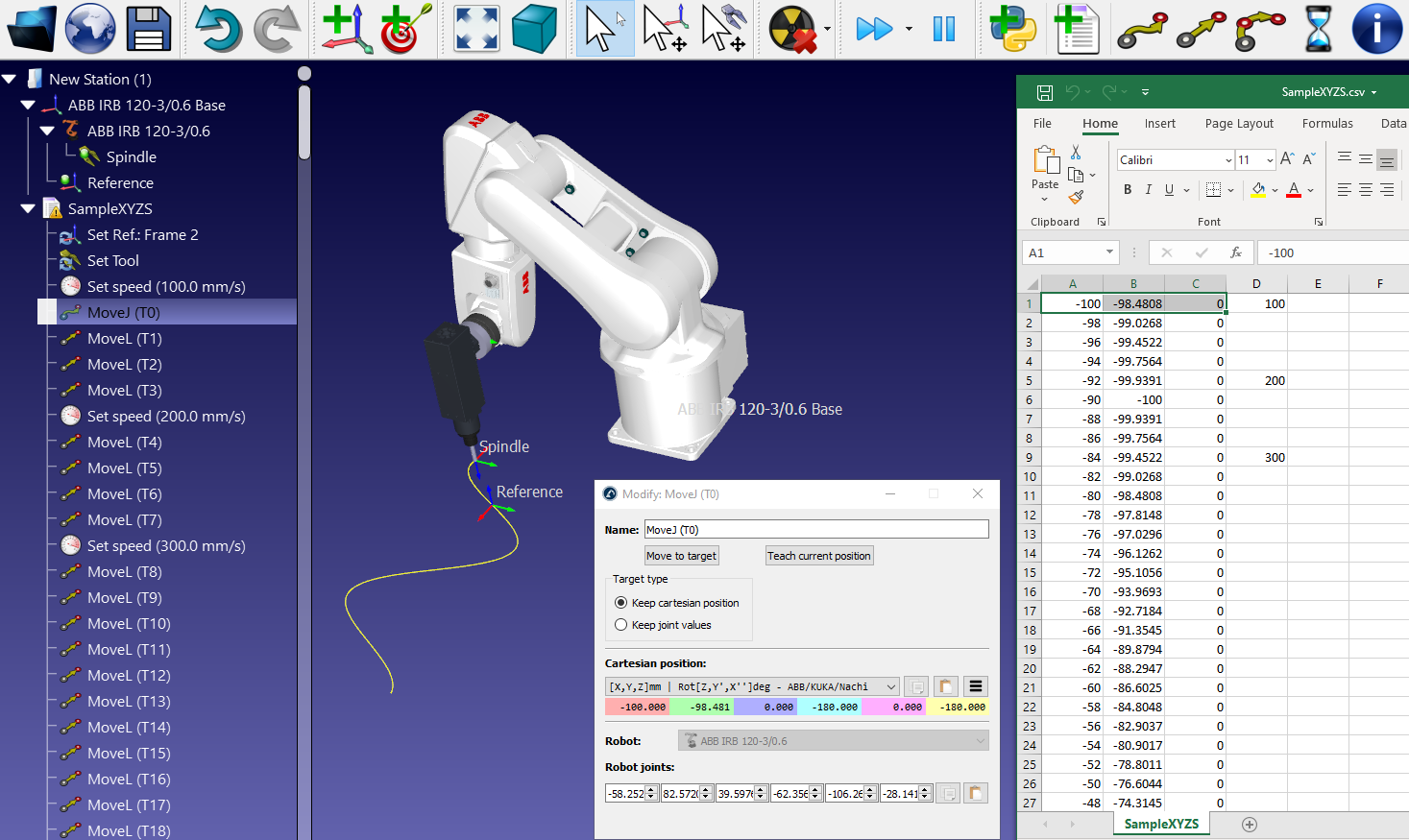

6.6. CSV file to Program (XYZ)¶

This example shows how to import targets from a CSV file given a list of XYZ coordinates. Optionally, the 4th column will update the speed in the program.

This example is available as a RoboDK script by default:

Select Tools-Run Script

Select ImportCSV_XYZ

Select a CSV file (Example: C:/RoboDK/Library/Scripts/SampleXYZS.csv)

- Notes:

The tool orientation of the robot is used as a reference when creating the targets.

XYZ values must be provided in millimeters, the speed must be provided in mm/s.

The active tool and reference frame will be used in the program.

The program will have instructions hidden, you can right click a program and select “Show instructions” to display the instructions.

You can select one or more movement instructions and select “Select targets” to see the targets.

# This macro shows how to load a list of XYZ points including speed

# The list must be provided as X,Y,Z,Speed. Units must be mm and mm/s respectively

from robodk.robolink import *

from robodk.robodialogs import *

from robodk.robofileio import *

#----------------------------

# Global variables:

# LOAD_AS_PROGRAM flag:

# Set to True to generate a program in the UI: we can modify targets manually and properly see the program

# Set to False, it will simulate or generate the robot program directly when running the macro

LOAD_AS_PROGRAM = True

# Set the name of the reference frame to place the targets:

REFERENCE_NAME = 'Reference CSV'

# Set the name of the reference target

# (orientation will be kept constant with respect to this target)

TARGET_NAME = 'Home'

#---------------------------

# Start the RoboDK API

RDK = Robolink()

# Ask the user to pick a file:

rdk_file_path = RDK.getParam("PATH_OPENSTATION")

path_file = getOpenFileName(rdk_file_path + "/")

if not path_file:

print("Nothing selected")

quit()

# Get the program name from the file path

program_name = getFileName(path_file)

# Load the CSV file as a list of list [[x,y,z,speed],[x,y,z,speed],...]

data = LoadList(path_file)

# Delete previously generated programs that follow a specific naming

#list_names = RDK.ItemList(False)

#for item_name in list_names:

# if item_name.startswith('Auto'):

# RDK.Item(item_name).Delete()

# Select the robot (the popup is diplayed only if there are 2 or more robots)

robot = RDK.ItemUserPick('Select a robot', ITEM_TYPE_ROBOT)

if not robot.Valid():

raise Exception("Robot not selected or not valid")

quit()

# Get the reference frame to generate the path

frame = RDK.Item(REFERENCE_NAME, ITEM_TYPE_FRAME)

if not frame.Valid():

raise Exception("Reference frame not found. Use name: %s" % REFERENCE_NAME)

# Use the home target as a reference

target = RDK.Item(TARGET_NAME, ITEM_TYPE_TARGET)

if not target.Valid():

raise Exception("Home target is not valid. Set a home target named: %s" % TARGET_NAME)

# Set the robot to the home position

robot.setJoints(target.Joints())

# Get the pose reference from the home target

pose_ref = robot.Pose()

if LOAD_AS_PROGRAM:

# Add a new program

program = RDK.AddProgram(program_name, robot)

# Turn off rendering (faster)

RDK.Render(False)

# Speed up by not showing the instruction:

program.ShowInstructions(False)

# Remember the speed so that we don't set it with every instruction

current_speed = None

target = None

# Very important: Make sure we set the reference frame and tool frame so that the robot is aware of it

program.setPoseFrame(frame)

program.setPoseTool(robot.PoseTool())

# Iterate through all the points

for i in range(len(data)):

pi = pose_ref

pi.setPos(data[i])

# Update speed if there is a 4th column

if len(data[i]) >= 3:

speed = data[i][3]

# Update the program if the speed is different than the previously set speed

if type(speed) != str and speed != current_speed:

program.setSpeed(speed)

current_speed = speed

target = RDK.AddTarget('T%i' % i, frame)

target.setPose(pi)

pi = target

# Add a linear movement (with the exception of the first point which will be a joint movement)

if i == 0:

program.MoveJ(pi)

else:

program.MoveL(pi)

# Update from time to time to notify the user about progress

if i % 100 == 0:

program.ShowTargets(False)

RDK.ShowMessage("Loading %s: %.1f %%" % (program_name, 100 * i / len(data)), False)

RDK.Render()

program.ShowTargets(False)

else:

# Very important: Make sure we set the reference frame and tool frame so that the robot is aware of it

robot.setPoseFrame(frame)

robot.setPoseTool(robot.PoseTool())

# Remember the speed so that we don't set it with every instruction

current_speed = None

# Iterate through all the points

for i in range(len(data)):

pi = pose_ref

pi.setPos(data[i][0:3])

# Update speed if there is a 4th column

if len(data[i]) >= 3:

speed = data[i][3]

# Update the program if the speed is different than the previously set speed

if type(speed) != str and speed != current_speed:

robot.setSpeed(speed)

current_speed = speed

# Add a linear movement (with the exception of the first point which will be a joint movement)

if i == 0:

robot.MoveJ(pi)

else:

robot.MoveL(pi)

# Update from time to time to notify the user about progress

#if i % 200 == 0:

RDK.ShowMessage("Program %s: %.1f %%" % (program_name, 100 * i / len(data)), False)

RDK.ShowMessage("Done", False)

print("Done")

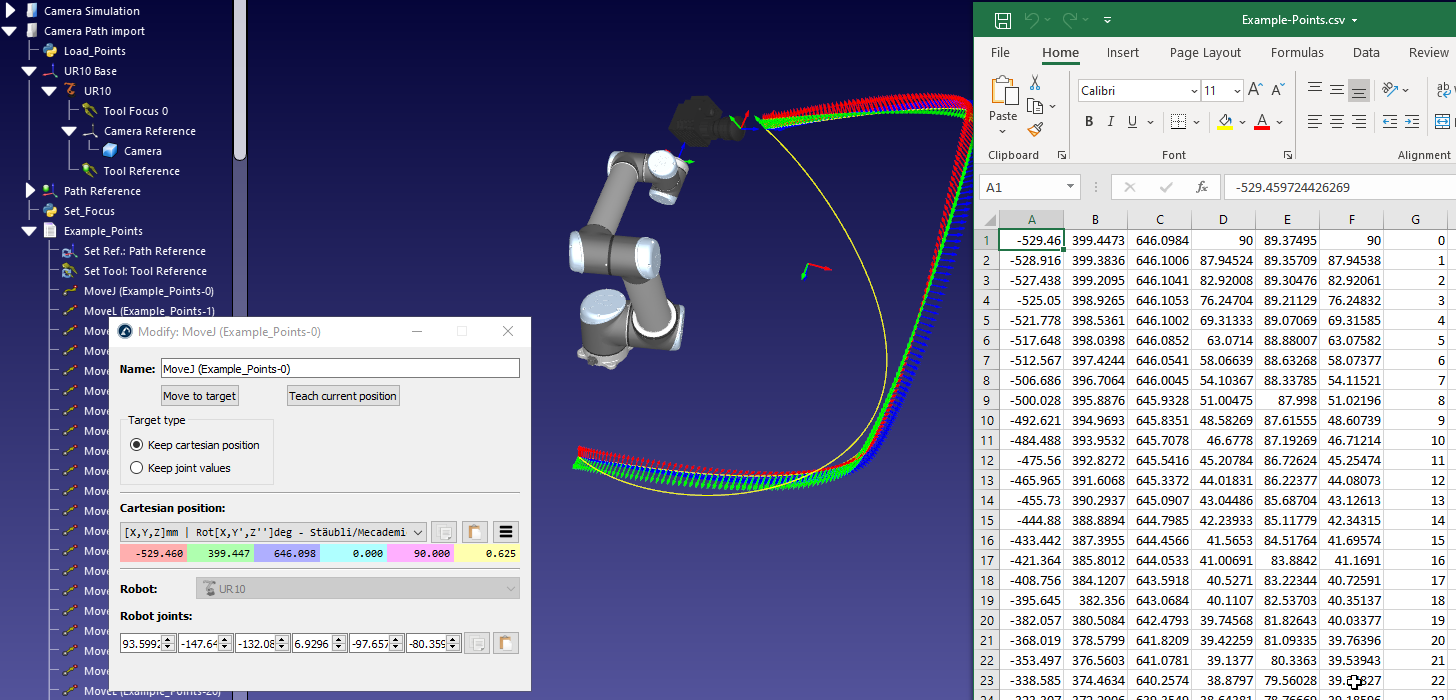

6.7. CSV file to Program (XYZWPR)¶

This example shows how to import targets from a CSV file given a list of XYZWPR coordinates (poses).

- This example is available as a RoboDK script by default:

Select Tools-Run Script

Select ImportCSV_XYZWPR

Select a CSV file (Example: C:/RoboDK/Library/Scripts/ImportCSV_XYZWPR.csv)

- Notes:

The Euler format Z->Y’->X’’ for target orientation is used in this example (it can be easily changed using rotx, roty and rotz functions)

XYZ values must be provided in millimeters, Rx, Ry, Rz values must be provided in degrees.

The active tool and reference frame will be used in the program.

The program will have instructions hidden, you can right click a program and select Show instructions to display the instructions.

You can select one or more movement instructions and select “Select targets” to see the targets.

# This macro can load CSV files from Denso programs in RoboDK.

# Supported types of files are:

# 1-Tool data : Tool.csv

# 2-Work object data: Work.csv

# 3-Target data: P_Var.csv

# This macro can also filter a given targets file

# Type help("robodk.robolink") or help("robodk.robomath") for more information

# Press F5 to run the script

# Visit: http://www.robodk.com/doc/PythonAPI/

# For RoboDK API documentation

from robodk.robolink import * # API to communicate with RoboDK

from robodk.robomath import * # Robot toolbox

from robodk.robodialogs import *

from robodk.robofileio import *

# Start communication with RoboDK

RDK = Robolink()

# Ask the user to select the robot (ignores the popup if only

ROBOT = RDK.ItemUserPick('Select a robot', ITEM_TYPE_ROBOT)

# Check if the user selected a robot

if not ROBOT.Valid():

quit()

# Automatically retrieve active reference and tool

FRAME = ROBOT.getLink(ITEM_TYPE_FRAME)

TOOL = ROBOT.getLink(ITEM_TYPE_TOOL)

#FRAME = RDK.ItemUserPick('Select a reference frame', ITEM_TYPE_FRAME)

#TOOL = RDK.ItemUserPick('Select a tool', ITEM_TYPE_TOOL)

if not FRAME.Valid() or not TOOL.Valid():

raise Exception("Select appropriate FRAME and TOOL references")

# Function to convert XYZWPR to a pose

# Important! Specify the order of rotation

def xyzwpr_to_pose(xyzwpr):

x, y, z, rx, ry, rz = xyzwpr

return transl(x, y, z) * rotz(rz * pi / 180) * roty(ry * pi / 180) * rotx(rx * pi / 180)

#return transl(x,y,z)*rotx(rx*pi/180)*roty(ry*pi/180)*rotz(rz*pi/180)

#return KUKA_2_Pose(xyzwpr)

# csv_file = 'C:/Users/Albert/Desktop/Var_P.csv'

csv_file = getOpenFileName(RDK.getParam('PATH_OPENSTATION'))

# Specify file codec

codec = 'utf-8' #'ISO-8859-1'

# Load P_Var.CSV data as a list of poses, including links to reference and tool frames

def load_targets(strfile):

csvdata = LoadList(strfile, ',', codec)

poses = []

idxs = []

for i in range(0, len(csvdata)):

x, y, z, rx, ry, rz = csvdata[i][0:6]

poses.append(xyzwpr_to_pose([x, y, z, rx, ry, rz]))

#idxs.append(csvdata[i][6])

idxs.append(i)

return poses, idxs

# Load and display Targets from P_Var.CSV in RoboDK

def load_targets_GUI(strfile):

poses, idxs = load_targets(strfile)

program_name = getFileName(strfile)

program_name = program_name.replace('-', '_').replace(' ', '_')

program = RDK.Item(program_name, ITEM_TYPE_PROGRAM)

if program.Valid():

program.Delete()

program = RDK.AddProgram(program_name, ROBOT)

program.setFrame(FRAME)

program.setTool(TOOL)

ROBOT.MoveJ(ROBOT.JointsHome())

for pose, idx in zip(poses, idxs):

name = '%s-%i' % (program_name, idx)

target = RDK.Item(name, ITEM_TYPE_TARGET)

if target.Valid():

target.Delete()

target = RDK.AddTarget(name, FRAME, ROBOT)

target.setPose(pose)

try:

program.MoveJ(target)

except:

print('Warning: %s can not be reached. It will not be added to the program' % name)

def load_targets_move(strfile):

poses, idxs = load_targets(strfile)

ROBOT.setFrame(FRAME)

ROBOT.setTool(TOOL)

ROBOT.MoveJ(ROBOT.JointsHome())

for pose, idx in zip(poses, idxs):

try:

ROBOT.MoveJ(pose)

except:

RDK.ShowMessage('Target %i can not be reached' % idx, False)

# Force just moving the robot after double clicking

#load_targets_move(csv_file)

#quit()

# Recommended mode of operation:

# 1-Double click the python file creates a program in RoboDK station

# 2-Generate program generates the program directly

MAKE_GUI_PROGRAM = False

ROBOT.setFrame(FRAME)

ROBOT.setTool(TOOL)

if RDK.RunMode() == RUNMODE_SIMULATE:

MAKE_GUI_PROGRAM = True

# MAKE_GUI_PROGRAM = mbox('Do you want to create a new program? If not, the robot will just move along the tagets', 'Yes', 'No')

else:

# if we run in program generation mode just move the robot

MAKE_GUI_PROGRAM = False

if MAKE_GUI_PROGRAM:

RDK.Render(False) # Faster if we turn render off

load_targets_GUI(csv_file)

else:

load_targets_move(csv_file)

6.8. Load a KUKA SRC file¶

This example shows how to import a KUKA SRC file as a robot program. Make sure to first load your KUKA robot in RoboDK (the one used for the SRC program), then, run this script using Tools -> Run-Script.

# This macro shows how to load a KUKA SRC file

# PTP movements with joint coordinates and LIN movements with Cartesian information (XYZABC) will be imported as a program.

# This macro also supports defining the tool and the base inline and changing the speed using the VEL.CP global variable

## Example program:

# DEF Milling ( )

#

# $BASE = {FRAME: X 0.000,Y -1000.000,Z 0.000,A 0.000,B 0.000,C 0.000}

# $TOOL = {FRAME: X 466.604,Y -4.165,Z 109.636,A -0.000,B 90.000,C 0.000}

#

# $VEL.CP = 1.00000

#

# PTP {A1 107.78457,A2 -44.95260,A3 141.64681,A4 107.66839,A5 -87.93467,A6 6.37710}

# LIN {X -0.000,Y -0.000,Z 6.350,A -180.000,B 0.000,C -180.000}

#

# $VEL.CP = 0.02117

# LIN {X 276.225,Y 0.000,Z 6.350,A 180.000,B 0.000,C -180.000}

# LIN {X 276.225,Y 323.850,Z 6.350,A -160.000,B 0.000,C 180.000}

# LIN {X -0.000,Y 323.850,Z 6.350,A -180.000,B -0.000,C -180.000}

# LIN {X -0.000,Y -0.000,Z 6.350,A -180.000,B 0.000,C -180.000}

# $VEL.CP = 1.00000

# LIN {X -0.000,Y -0.000,Z 106.350,A -180.000,B 0.000,C -180.000}

#

# END

from robodk.robomath import * # Robot toolbox

from robodk.robodialogs import *

from robodk.robofileio import *

from robodk.robolink import *

#---------------------------

# Start the RoboDK API

RDK = Robolink()

# Ask the user to pick an SRC file:

rdk_file_path = RDK.getParam("PATH_OPENSTATION")

src_file_path = getOpenFileName(rdk_file_path + "/")

if not src_file_path:

print("Nothing selected")

quit()

# Get the program name from the file path

program_name = getFileName(src_file_path)

print("Loading program: " + program_name)

if not src_file_path.lower().endswith(".src"):

raise Exception("Invalid file selected. Select an SRC file.")

def GetValues(line):

"""Get all the numeric values from a line"""

# LIN {X 1671.189,Y -562.497,Z -243.070,A 173.363,B -8.525,C -113.306} C_DIS

line = line.replace(",", " ")

line = line.replace("}", " ")

values = line.split(" ")

list_values = []

for value in values:

try:

value = float(value)

except:

continue

list_values.append(value)

return list_values

# Ask the user to select a robot (if more than a robot is available)

robot = RDK.ItemUserPick('Select a robot', ITEM_TYPE_ROBOT)

if not robot.Valid():

raise Exception("Robot not selected or not valid")

# Get the active reference frame

frame = robot.getLink(ITEM_TYPE_FRAME)

if not frame.Valid():

# If there is no active reference frame, use the robot base

frame = robot.Parent()

# Get the active tool frame

tool = robot.getLink(ITEM_TYPE_TOOL)

# Add a new program

program = RDK.AddProgram(program_name, robot)

# Turn off rendering (faster)

RDK.Render(False)

# Speed up by not showing the instruction:

program.ShowInstructions(False)

# Open the file and iterate through each line

with open(src_file_path) as f:

count = 0

for line in f:

# Remove empty characters:

line = line.strip()

print("Loading line: " + line)

# Get all the numeric values in order

values = GetValues(line)

# Increase the counter

count = count + 1

# Update TCP speed (KUKA works in m/s, RoboDK works in mm/s)

if line.startswith("$VEL.CP"):

program.setSpeed(values[0]*1000)

continue

# Check operations that involve a pose

if len(values) < 6:

print("Warning! Invalid line: " + line)

continue

# Check what instruction we need to add:

if line.startswith("LIN"):

target = RDK.AddTarget('T%i'% count, frame)

# Check if we have external axes information, if so, provided it to joints E1 to En

if len(values) > 6:

target.setJoints([0,0,0,0,0,0] + values[6:])

target.setPose(KUKA_2_Pose(values[:6]))

program.MoveL(target)

# Check PTP move

elif line.startswith("PTP"):

target = RDK.AddTarget('T%i'% count, frame)

target.setAsJointTarget()

target.setJoints(values)

program.MoveJ(target)

# Set the tool

elif line.startswith("$TOOL"):

pose = KUKA_2_Pose(values[:6])

tool = robot.AddTool(pose, "SRC TOOL")

program.setTool(tool)

# Set the reference frame

elif line.startswith("$BASE"):

frame = RDK.AddFrame("SRC BASE", robot.Parent())

frame.setPose(KUKA_2_Pose(values[:6]))

program.setFrame(frame)

# Hide the targets

program.ShowTargets(False)

# Show the instructions

program.ShowInstructions(True)

RDK.ShowMessage("Done", False)

print("Done")

6.9. Test Move Feasibility¶

This example creates a program that safely moves the robot through a set of points checking that linear movements can be achieved (including collision checking or not). The points are automatically created as a cube grid around a reference target. If a linear movement can’t be achieved from one point to the next the robot will try a joint movement if a joint movement is also not possible the point will be skipped.

# This macro shows how you can create a program that moves the robot through a set of points

# The points are automatically created as a cube grid around a reference target

# If a linear movement can't be done from one point to the next one the robot will follow a joint movement

from robodk.robolink import * # API to communicate with RoboDK

from robodk.robomath import * # basic matrix operations

from random import uniform # to randomly calculate rz (rotation around the Z axis)

# Name of the reference target

REFERENCE_TARGET = 'RefTarget'

# Check for collisions

CHECK_COLLISIONS = False

#Start the RoboDK API

RDK = Robolink()

# Set collision checking ON or OFF

RDK.setCollisionActive(COLLISION_ON if CHECK_COLLISIONS else COLLISION_OFF)

# Run on robot: Force the program to run on the connected robot (same behavior as right clicking the program, then, selecting "Run on Robot")

# RDK.setRunMode(RUNMODE_RUN_ROBOT)

# Get the main/only robot in the station

robot = RDK.Item('', ITEM_TYPE_ROBOT)

if not robot.Valid():

raise Exception("Robot not valid or not available")

# Get the active reference frame

frame = robot.getLink(ITEM_TYPE_FRAME)

if not frame.Valid():

frame = robot.Parent()

robot.setPoseFrame(frame)

# Get the reference pose with respect to the robot

frame_pose = robot.PoseFrame()

# Get the active tool

tool = robot.getLink(ITEM_TYPE_TOOL)

if not tool.Valid():

tool = robot.AddTool(transl(0, 0, 75), "Tool Grid")

robot.setPoseTool(tool)

# Get the target reference RefTarget

target_ref = RDK.Item(REFERENCE_TARGET, ITEM_TYPE_TARGET)

if not target_ref.Valid():

target_ref = RDK.AddTarget(REFERENCE_TARGET, frame, robot)

# Get the reference position (pose=4x4 matrix of the target with respect to the reference frame)

pose_ref = target_ref.Pose()

startpoint = target_ref.Joints()

config_ref = robot.JointsConfig(startpoint)

# Retrieve the tool pose

tool_pose = tool.PoseTool()

# Retrieve the degrees of freedom or axes (num_dofs = 6 for a 6 axis robot)

num_dofs = len(robot.JointsHome().list())

# Get the reference frame of the target reference

ref_frame = target_ref.Parent()

# Function definition to check if 2 robot configurations are the same

# Configurations are set as [Rear/Front,LowerArm/UpperArm,Flip/NonFlip] bits (int values)

def config_equal(config1, config2):

if config1[0] != config2[0] or config1[1] != config2[1] or config1[2] != config2[2]:

return False

return True

# Create a new program

prog = RDK.AddProgram('AutoCreated')

# This should make program generation slightly faster

#prog.ShowInstructions(False)

# Start creating the program or moving the robot:

program_or_robot = prog

program_or_robot.setPoseTool(tool_pose)

program_or_robot.MoveJ(target_ref)

lastjoints = startpoint

rz = 0

ntargets = 0

for tz in range(-100, 101, 100):

for ty in range(0, 401, 200):

for tx in range(100, -5001, -250):

ntargets = ntargets + 1

# calculate a random rotation around the Z axis of the tool

#rz = uniform(-20*pi/180, 20*pi/180)

# Calculate the position of the new target: translate with respect to the robot base and rotate around the tool

newtarget_pose = transl(tx, ty, tz) * pose_ref * rotz(rz)

# First, make sure the target is reachable:

newtarget_joints = robot.SolveIK(newtarget_pose, lastjoints, tool_pose, frame_pose)

if len(newtarget_joints.list()) < num_dofs:

print('...target not reachable!! Skipping target')

continue

# Create a new target:

newtarget_name = 'Auto T%.0f,%.0f,%.0f Rz=%.1f' % (tx, ty, tz, rz)

print('Creating target %i: %s' % (ntargets, newtarget_name))

newtarget = RDK.AddTarget(newtarget_name, ref_frame, robot)

# At this point, the target is reachable.

# We have to check if we can do a linear move or not. We have 2 methods:

can_move_linear = True

# ------------------------------

# Validation method 1: check the joints at the destination target

# and make sure we have the same configuration

# A quick way to validate (it may not be perfect if robot joints can move more than 1 turn)

# To improve this method we would have to check configurations on all possible solutions

# from the inverse kinematics, using SolveIK_All()

if False:

target_joints_config = robot.JointsConfig(newtarget_joints)

if not config_equal(config_ref, target_joints_config):

# We can't do a linear movement

can_move_linear = False

print("Warning! configuration is not the same as the reference target! Linear move will not be possible")

# update the reference configuration to the new one

config_ref = target_joints_config

# -------------------------------

# -------------------------------

# Validation method 2: use the robot.MoveL_Test option to check if the robot can make a linear movement

# This method is more robust and should provide a 100% accurate result but it may take more time

# robot.MoveL_Test can also take collisions into account if collision checking is activated

issues = robot.MoveL_Test(lastjoints, newtarget_pose)

can_move_linear = (issues == 0)

# We can retrieve the final joint position by retrieving the robot joints

if can_move_linear:

newtarget_joints = robot.Joints()

# ---------------------------------

if can_move_linear:

# All good, we don't need to modify the target.

# However, we could set the joints in the target as this may allow us to retrieve the robot configuration if we ever need it

newtarget.setAsCartesianTarget() # default behavior

newtarget.setJoints(newtarget_joints)

# It is important to have setPose after setJoints as it may recalculate the joints to match the target

newtarget.setPose(newtarget_pose)

# Add the linear movement

program_or_robot.MoveL(newtarget)

else:

#print(newtarget_joints)

# Check if we can do a joint movement (check for collisions)

issues = robot.MoveJ_Test(lastjoints, newtarget_joints)

can_move_joints = (issues == 0)

if not can_move_joints:

# Skip this point

print("Skipping movement to: " + str(newtarget_joints))

continue

# Make sure we have a joint target and a joint movement

newtarget.setAsJointTarget() # default behavior

# Setting the pose for a joint target is not important unless we want to retrieve the pose later

# or we want to use the Cartesian coordinates for post processing

newtarget.setPose(newtarget_pose)

# Make sure we set the joints after the pose for a joint taget as it may recalculate the pose

newtarget.setJoints(newtarget_joints)

# Add the joint movement

program_or_robot.MoveJ(newtarget)

# Remember the joint poisition of the last movement

lastjoints = newtarget_joints

# Showing the instructions at the end is faster:

prog.ShowInstructions(True)

# Hiding the targets is cleaner and more difficult to accidentaly move a target

#prog.ShowTargets(False)

print('Program done with %i targets' % ntargets)

6.10. Docked UI¶

This example shows how to embed a window in RoboDK. In this case a GUI window created with TKInter is added as a docked window in RoboDK.

from tkinter import *

from robodk.robolink import *

import tkinter

import threading

# Create a new window

window = Tk()

# Close the window

def onClose():

window.destroy()

quit(0)

# Trigger Select button

# IMPORTANT: We need to run the action on a separate thread because

# (otherwise, if we want to interact with RoboDK window it will freeze)

def on_btnSelect():

def thread_btnSelect():

# Run button action (example to select an item and display its name)

RDK = Robolink()

item = RDK.ItemUserPick('Select an item')

if item.Valid():

RDK.ShowMessage("You selected the item: " + item.Name())

threading.Thread(target=thread_btnSelect).start()

# Set the window title (must be unique for the docking to work, try to be creative)

window_title = 'RoboDK API Docked Window'

window.title(window_title)

# Delete the window when we close it

window.protocol("WM_DELETE_WINDOW", onClose)

# Add a button (Select action)

btnSelect = Button(window, text='Trigger on_btnSelect', height=5, width=60, command=on_btnSelect)

btnSelect.pack(fill=X)

# Embed the window

EmbedWindow(window_title)

# Run the window event loop. This is like an app and will block until we close the window

window.mainloop()

6.11. Estimated cycle time¶

This example shows how to calculate estimated cycle times.

- More information about how RoboDK estimates cycle times here:

# This example shows how to quickly calculate the cycle time of a program

# as a function of the linear and joint speeds

#

# Important notes and tips for accurate cycle time calculation:

# https://robodk.com/doc/en/General.html#CycleTime

# Start the RoboDK API

from robodk.robolink import * # RoboDK API

RDK = Robolink()

# Ask the user to select a program

program = RDK.ItemUserPick('Select a program (make sure the program does not change the robot speed)', ITEM_TYPE_PROGRAM)

# Retrieve the robot linked to the selected program

robot = program.getLink(ITEM_TYPE_ROBOT)

# Output the linear speed, joint speed and time (separated by tabs)

writeline = "Linear Speed (mm/s)\tJoint Speed (deg/s)\tCycle Time(s)"

print(writeline)

# Prepare an HTML message we can show to the user through the RoboDK API:

msg_html = "<table border=1><tr><td>" + writeline.replace('\t', '</td><td>') + "</td></tr>"

for speed_lin in [1, 5, 10, 20, 50, 100, 200, 500]:

for speed_joints in [1, 5, 10, 20, 50, 100, 200, 500]:

# Set the robot speed

robot.setSpeed(speed_lin, speed_joints)

# Update the program and retrieve updated information:

# https://robodk.com/doc/en/PythonAPI/robodk.html#robodk.robolink.Item.Update

result = program.Update()

instructions, time, travel, ok, error = result

# Print the information

newline = "%.1f\t%.1f\t%.1f" % (speed_lin, speed_joints, time)

print(newline)

msg_html = msg_html + '<tr><td>' + newline.replace('\t', '</td><td>') + '</td></tr>'

msg_html = msg_html + '</table>'

RDK.ShowMessage(msg_html)

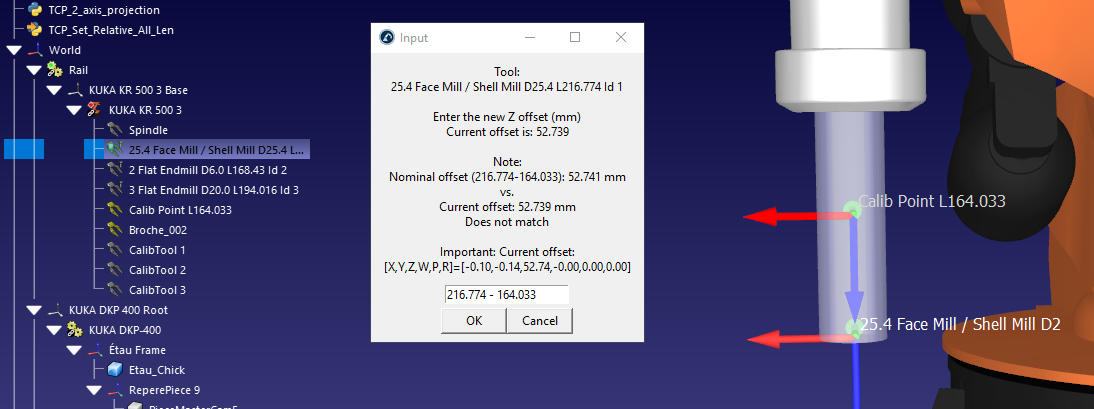

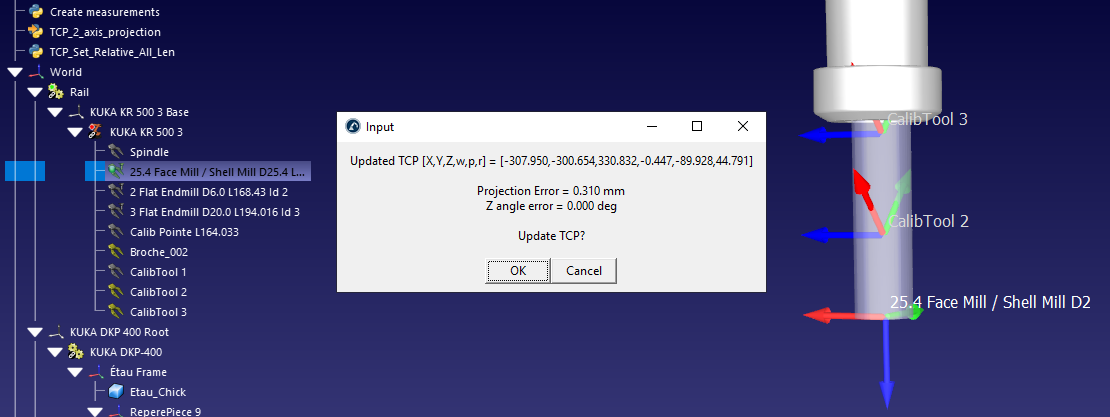

6.12. Change tool¶

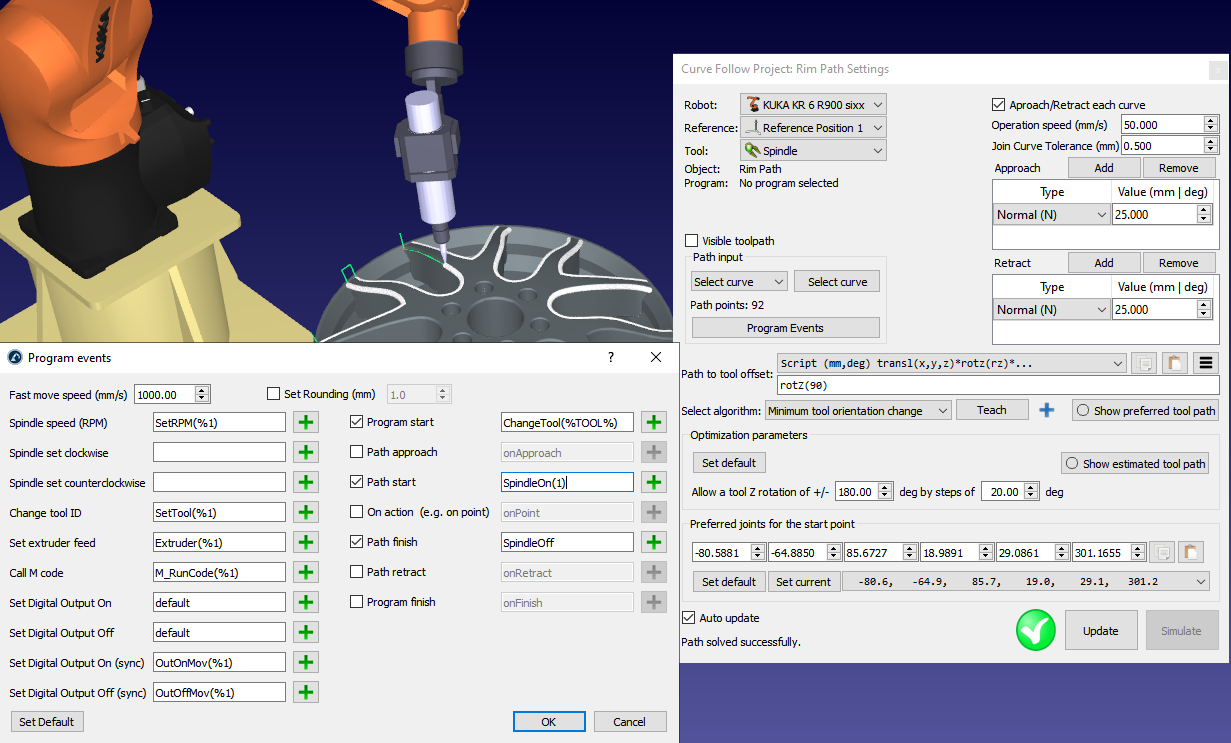

This macro allows updating the tool given an ID that is passed as an argument for robot machining purposes. If no ID is passed as argument it will pop up a message. This macro can be used together with a robot machining project to change the tool as it simulates. Double click your robot machining project, select Program Events, and enter SetTool(%1) for a tool change event.

# This macro allows updating the tool given an ID that is passed as an argument

# If no ID is passed as argument it will pop up a message

# This macro can be used together with a robot machining project to change the tool as it simulates

# Double click your robot machining project, select Program Events, and enter SetTool(%1) on change tool event

# https://robodk.com/doc/en/RoboDK-API.html

import sys # allows getting the passed argument parameters

from robodk.robolink import *

from robodk.robodialogs import *

RDK = Robolink()

TOOL_ID = 0

if len(sys.argv) >= 2:

TOOL_ID = int(sys.argv[1])

else:

tool_str = mbox("Enter the tool number:\n(for example, for Tool 1 set 1)", entry='1')

if not tool_str:

# No input

quit()

TOOL_ID = int(tool_str)

# Select a robot

robot = RDK.Item('', ITEM_TYPE_ROBOT)

if not robot.Valid():

raise Exception("Robot not available")

# Create the tool name

tool_name = 'Tool ' + str(TOOL_ID)

print("Using robot: " + robot.Name())

print("Setting tool: " + tool_name)

# Select the tool

tool = RDK.Item(tool_name, ITEM_TYPE_TOOL)

if not tool.Valid():

raise Exception("Tool %s does not exist!" % tool_name)

# Update the robot to use the tool

robot.setTool(tool)

print("Done!")

6.13. Project curve to surface¶

This example projects the features (points/curves) to a surface and calculates the normals to the surface. This example takes 2 objects: (1) an object with curves and/or points and (2) an object with one or more surfaces.

# This example takes 2 objects:

# 1 - Object with features (curves and/or points)

# 2 - Object with surface (additional features are ignored)

# This example projects the features (points/curves) to the reference surface and calculates the normals to the surface

from robodk.robolink import * # RoboDK API

RDK = Robolink()

# Set to True to invert the normals (flip the normals)

FlipNormals = False

# Set the type of projection

ProjectionType = PROJECTION_ALONG_NORMAL_RECALC

# Available values include:

#PROJECTION_NONE = 0 # No curve projection

#PROJECTION_CLOSEST = 1 # The projection will be the closest point on the surface

#PROJECTION_ALONG_NORMAL = 2 # The projection will be done along the normal.

#PROJECTION_ALONG_NORMAL_RECALC = 3 # The projection will be done along the normal. Furthermore, the normal will be recalculated according to the surface normal.

#PROJECTION_CLOSEST_RECALC = 4 # The projection will be the closest point on the surface and the normals will be recalculated

#PROJECTION_RECALC = 5 # The normals are recalculated according to the surface normal of the closest projection

#-------------------------------------------------------------

# Ask the user to provide the object with the features

object_features = RDK.ItemUserPick("Select object with the features to project (curves and/or points)", ITEM_TYPE_OBJECT)

if not object_features.Valid():

quit()

# Ask the user to provide the object with the surface used as a reference

object_surface = RDK.ItemUserPick("Select Surface Object to project features", ITEM_TYPE_OBJECT)

if not object_surface.Valid():

quit()

# Create a duplicate copy of the surface object

object_surface.Copy()

new_object = RDK.Paste(object_surface.Parent())

new_object.setName("Recalculated Normals")

new_object.setVisible(True)

# Hide the objects used to build the new object with the desired curves

object_features.setVisible(False)

object_surface.setVisible(False)

# Turn Off rendering (faster)

RDK.Render(False)

# Add all curves, projected as desired (iterate through all curves until no more curves are found)

curve_id = 0

while True:

# Retrieve the curve points

curve_points, name_feature = object_features.GetPoints(FEATURE_CURVE, curve_id)

print(name_feature)

curve_id = curve_id + 1

npoints = len(curve_points)

if npoints == 0:

break

print("Adding curve %s with %i points" % (name_feature, npoints))

curve_points_proj = RDK.ProjectPoints(curve_points, object_surface, ProjectionType)

# Optionally flip the normals (ijk vector)

if FlipNormals:

for ci in range(len(curve_points_proj)):

x, y, z, i, j, k = curve_points_proj[ci]

curve_points_proj[ci] = [x, y, z, -i, -j, -k]

RDK.AddCurve(curve_points_proj, new_object, True, PROJECTION_NONE)

# Add all points projected

point_list, name_feature = object_features.GetPoints(FEATURE_POINT)

npoints = len(point_list)

print("Adding %i points" % npoints)

if npoints > 0:

#RDK.AddPoints(point_list, new_object, True, PROJECTION_ALONG_NORMAL_RECALC)

point_list_proj = RDK.ProjectPoints(point_list, object_surface, ProjectionType)

RDK.AddPoints(point_list_proj, new_object, True, PROJECTION_NONE)

#RDK.AddCurve(curve_points, new_object, True, PROJECTION_NONE)

# Set the curve width

new_object.setValue('DISPLAY', 'LINEW=2')

# Set the curve color

new_object.setColorCurve([0.0, 0.5, 0.5])

# Turn On rendering (Optional)

RDK.Render(True)

print("Done")

6.14. Filter curve normals¶

This macro shows how to average the normals of an object containing curves. This macro can also filter points that are too close to each other. The user must select an object, then, a copy of this object is created with the averaged normals.

# This macro shows how to average the normals of an object containing curves.

# This macro can also filter points that are too close to each other.

# The use must select an object, then, a copy of this object is created with the normals averaged.

# For more information about the RoboDK API:

# Documentation: https://robodk.com/doc/en/RoboDK-API.html

# Reference: https://robodk.com/doc/en/PythonAPI/index.html

#-------------------------------------------------------

# Enter the size of the average filter, in number of samples.

# If this value is set to -1 it will popup a message asking the user to enter a value

FilterNormalSamples = -1 # in samples

# Enter the distance, in mm, to filter close points.

# For example, if we want one point each 2 mm at most, we should enter 2.

# Set to -1 to not filter the number of points.

FilterPointDistance = -1 # in mm

# ------------------------------------------------------

# Start the RoboDK API

from robodk.robolink import * # RoboDK API

from robodk.robomath import * # Robot toolbox

from robodk.robodialogs import *

RDK = Robolink()

# Ask the user to select the object

obj = RDK.ItemUserPick("Select the object or the tool to filter curves") # we can optionally filter by ITEM_TYPE_OBJECT or ITEM_TYPE_TOOL (not both)

# Exit if the user selects cancel

if not obj.Valid():

quit()

# Ask the user to enter the filter size

if FilterNormalSamples <= 0:

str_avg_filter = mbox("Enter the filter size (the number of points/normals used for the average filter).\nFor example, if the filter size is 10 units, the 10 closest normals are used to average each individual normal.", entry="10")

if not str_avg_filter:

# The user selected cancel

quit()

# Convert the user input to an integer

FilterNormalSamples = int(str_avg_filter)

if FilterNormalSamples <= 0:

RDK.ShowMessage("Invalid Filter value. Enter a value >= 1", False)

raise Exception(msg)

# Iterate through all object curves, extract the curve points and average the normals

curve_id = 0

obj_filtered = None

while True:

points, name_feature = obj.GetPoints(FEATURE_CURVE, curve_id)

# points is a double array of float with np points and xyzijk data for each point

# point[np] = [x,y,z,i,j,k] # where xyz is the position and ijk is the tool orientation (Z axis, usually the normal to the surface)

np = len(points)

# when curve_id is out of bounds, an empty double array is returned

if np == 0 or len(points[0]) < 6:

break

msg = "Filtering: " + name_feature

print(msg)

RDK.ShowMessage(msg, False)

curve_id = curve_id + 1

# For each point, average the normals in the range of points [-FilterNormalSamples/2 ; +FilterNormalSamples/2]

new_normals = []

for i in range(np):

id_avg_from = round(max(0, i - 0.5 * FilterNormalSamples))

id_avg_to = round(min(np - 1, i + 0.5 * FilterNormalSamples))

# Make sure we account for the start and end sections (navg is usually FilterNormalSamples, except near the borders)

n_avg = id_avg_to - id_avg_from

normal_i = [0, 0, 0]

for j in range(id_avg_from, id_avg_to):

ni = points[j][3:6]

normal_i = add3(normal_i, ni)

# Normalize

normal_i = normalize3(normal_i)

#this would not be correct: normal_i = mult3(normal_i, 1.0/n_avg)

# Add the new normal to the list

new_normals.append(normal_i)

# Combine the normals with the list of points

for i in range(np):

points[i][3:6] = new_normals[i][0:3]

# Filter points, if desired

if FilterPointDistance > 0:

lastp = None

points_filtered = []

points_filtered.append(points[0])

lastp = points[0]

for i in range(1, np):

if distance(lastp, points[i]) > FilterPointDistance:

points_filtered.append(points[i])

lastp = points[i]

points = points_filtered

# For the first curve: create a new object, rename it and place it in the same location of the original object

if obj_filtered is None:

obj_filtered = RDK.AddCurve(points, 0, False, PROJECTION_NONE)

obj_filtered.setName(obj.Name() + " Filtered")

obj_filtered.setParent(obj.Parent())

obj_filtered.setGeometryPose(obj_filtered.GeometryPose())

else:

# After the first curve has been added, add following curves to the same object

RDK.AddCurve(points, obj_filtered, True, PROJECTION_NONE)

# Set the curve display width

obj_filtered.setValue('DISPLAY', 'LINEW=2')

# Set the curve color as RGBA values [0-1.0]

obj_filtered.setColorCurve([0.0, 0.5, 1.0, 0.8])

6.15. Change curve normals¶

This example shows how to change the curve normal of an object to point in the +Z direction by changing the i, j and k vectors to (0,0,1).

#This Script changes the normals of the curve to point in +Z direction by changing the i,j,k vectors to (0,0,1)

#----------------------------------------

# Start the RoboDK API

from robodk.robolink import * # RoboDK API

RDK = Robolink()

# Ask the user to select the object

obj = RDK.ItemUserPick("Select the object or the tool to filter curves") # we can optionally filter by ITEM_TYPE_OBJECT or ITEM_TYPE_TOOL (not both)

# Exit if the user selects cancel

if not obj.Valid():

quit()

curve_list = []

i = 0

# Iterate through all object curves, extract the curve points and retrieve the curves in a list

while True:

curve_points, name_feature = obj.GetPoints(FEATURE_CURVE, i)

if len(curve_points) == 0:

break

i = i + 1

curve_list.append(curve_points)

# Retrieved list contains each points as [x,y,z,i,j,k]

# Change the i,j,k vectors to 0,0,1

for curve in curve_list:

for idx in range(len(curve)):

i, j, k = curve[idx][3:6]

curve[idx][3:6] = [0, 0, 1]

#print(new_curve)

#Add all maniplated curves as a new object

obj_new = None

for curve in curve_list:

obj_new = RDK.AddCurve(curve, obj_new, True, PROJECTION_NONE)

# Set the new object name and parent

obj_new.setName(obj.Name() + " New")

obj_new.setParent(obj.Parent())

obj_new.setGeometryPose(obj_new.GeometryPose())

# Set the curve display width

obj_new.setValue('Display', 'LINEW=4')

# Set the curve color as RGBA values [0-1.0]

obj_new.setColorCurve([0.0, 0.5, 1.0, 0.8])

#Delete all curves on the object first retrieved

obj.setParam("DeleteCurves")

6.16. Attach object to a robot link¶

This example shows how to attach an object to a robot link. Once you place the object at the preferred position, you can run the script in your RoboDK station.

# This script allows you to attach an object to a robot link

from robodk.robolink import * # API to communicate with RoboDK

from robodk.robodialogs import *

RDK = Robolink() # Initialize the RoboDK API

# Select the robot

# Add the shape to a robot link

robot = RDK.ItemUserPick('Select a robot to add an object', ITEM_TYPE_ROBOT)

if not robot.Valid():

raise Exception('No robot selected. Add a robot to attach this geometry to a link')

while True:

value = mbox('Enter the joint to attach the object to:\n' + robot.Name() + '\nExample: 0 is the base, 3 is joint 3', entry='3')

if not value:

quit(0)

link_id = int(value)

robotlink = robot.ObjectLink(link_id)

if robotlink.Valid():

break

RDK.ShowMessage("Invalid link. Select a valid robot link")

object = RDK.ItemUserPick('Select the object to add', ITEM_TYPE_OBJECT)

if not object.Valid():

raise Exception('Object not selected')

# List of objects to merge (first one must be the robot link)

merge = [robotlink, object]

# Merge the object

RDK.MergeItems(merge)

# Set original object invisible (or delete)

object.setVisible(False)

# object.Delete()

6.17. Move robot using a keyboard¶

This example shows how to move the robot using the keyboard. This macro needs to be executed as a separate process to properly intercept the keyboard (not within RoboDK). This example could be extended to move the robot using an Xbox controller, a Wii Remote or any other input device. You can find the Game Controller Add-in in the Add-in Marketplace.

# This macro allows moving a robot using the keyboard

# More information about the RoboDK API here:

# https://robodk.com/doc/en/RoboDK-API.html

# Type help("robodk.robolink") or help("robodk.robomath") for more information

# Press F5 to run the script

# Note: you do not need to keep a copy of this file, your python script is saved with the station

from robodk.robolink import * # API to communicate with RoboDK

from robodk.robomath import * # basic matrix operations

RDK = Robolink()

# Arrow keys program example

# get a robot

robot = RDK.Item('', ITEM_TYPE_ROBOT)

if not robot.Valid():

print("No robot in the station. Load a robot first, then run this program.")

pause(5)

raise Exception("No robot in the station!")

print('Using robot: %s' % robot.Name())

print('Use the arrows (left, right, up, down), Q and A keys to move the robot')

print('Note: This works on console mode only, you must run the PY file separately')

# define the move increment

move_speed = 10

from msvcrt import getch

while True:

key = (ord(getch()))

move_direction = [0, 0, 0]

# print(key)

if key == 75:

print('arrow left (Y-)')

move_direction = [0, -1, 0]

elif key == 77:

print('arrow right (Y+)')

move_direction = [0, 1, 0]

elif key == 72:

print('arrow up (X-)')

move_direction = [-1, 0, 0]

elif key == 80:

print('arrow down (X+)')

move_direction = [1, 0, 0]

elif key == 113:

print('Q (Z+)')

move_direction = [0, 0, 1]

elif key == 97:

print('A (Z-)')

move_direction = [0, 0, -1]

# make sure that a movement direction is specified

if norm(move_direction) <= 0:

continue

# calculate the movement in mm according to the movement speed

xyz_move = mult3(move_direction, move_speed)

# get the robot joints

robot_joints = robot.Joints()

# get the robot position from the joints (calculate forward kinematics)

robot_position = robot.SolveFK(robot_joints)

# get the robot configuration (robot joint state)

robot_config = robot.JointsConfig(robot_joints)

# calculate the new robot position

new_robot_position = transl(xyz_move) * robot_position

# calculate the new robot joints

new_robot_joints = robot.SolveIK(new_robot_position)

if len(new_robot_joints.tolist()) < 6:

print("No robot solution!! The new position is too far, out of reach or close to a singularity")

continue

# calculate the robot configuration for the new joints

new_robot_config = robot.JointsConfig(new_robot_joints)

if robot_config[0] != new_robot_config[0] or robot_config[1] != new_robot_config[1] or robot_config[2] != new_robot_config[2]:

print("Warning!! Robot configuration changed!! This will lead to unextected movements!")

print(robot_config)

print(new_robot_config)

else:

# move the robot joints to the new position

robot.MoveJ(new_robot_joints)

#robot.MoveL(new_robot_joints)

6.18. Connect to Robots¶

This example shows how to connect to all robots available in the RoboDK station using robot drivers and move the robot to the positions set in RoboDK. This example shows how to communicate with more than one robot at the same time.

- More information here:

Online programming using the RoboDK API for Python: https://robodk.com/doc/en/RoboDK-API.html#PythonAPIOnline

Robot drivers: https://robodk.com/doc/en/Robot-Drivers.html#RobotDrivers

# Type help("robodk.robolink") or help("robodk.robomath") for more information

# Press F5 to run the script

# More information about the RoboDK API here:

# https://robodk.com/doc/en/RoboDK-API.html