Path to tool offset

The path to tool offset allows changing the preferred orientation of the tool along the toolpath. This option is mainly used to turn the tool around the Z axis of the TCP. This allows handling the 6th degree of freedom around the tool axis. Several options are offered depending on the application and its requirements. For example, you can choose to minimize the tool orientation or follow the tool orientation along the path.

Since a 6-axis robot is used to follow a 3-axis or 5-axis CNC manufacturing program we have an additional degree of freedom to define. This degree of freedom is usually the rotation around the Z axis of the TCP. This additional degree of freedom is especially useful to avoid singularities, joint limits, collisions or reachability issues.

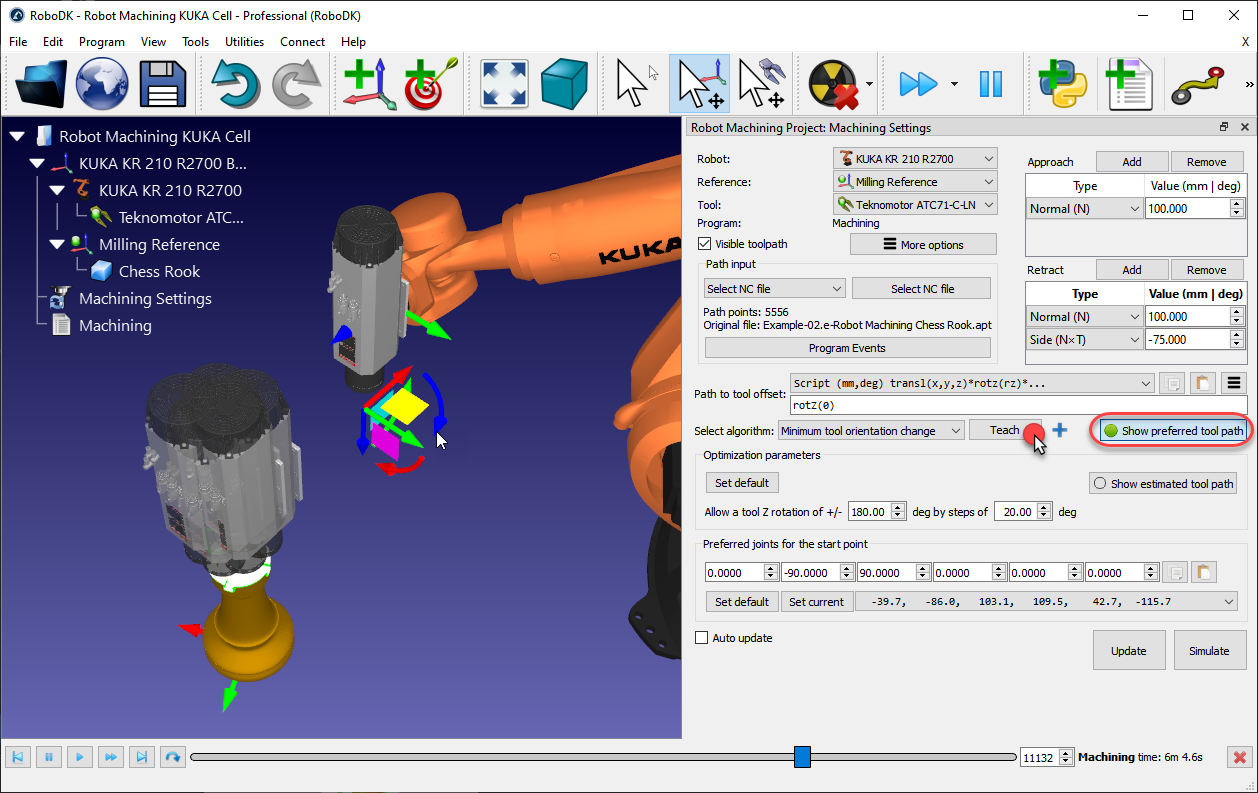

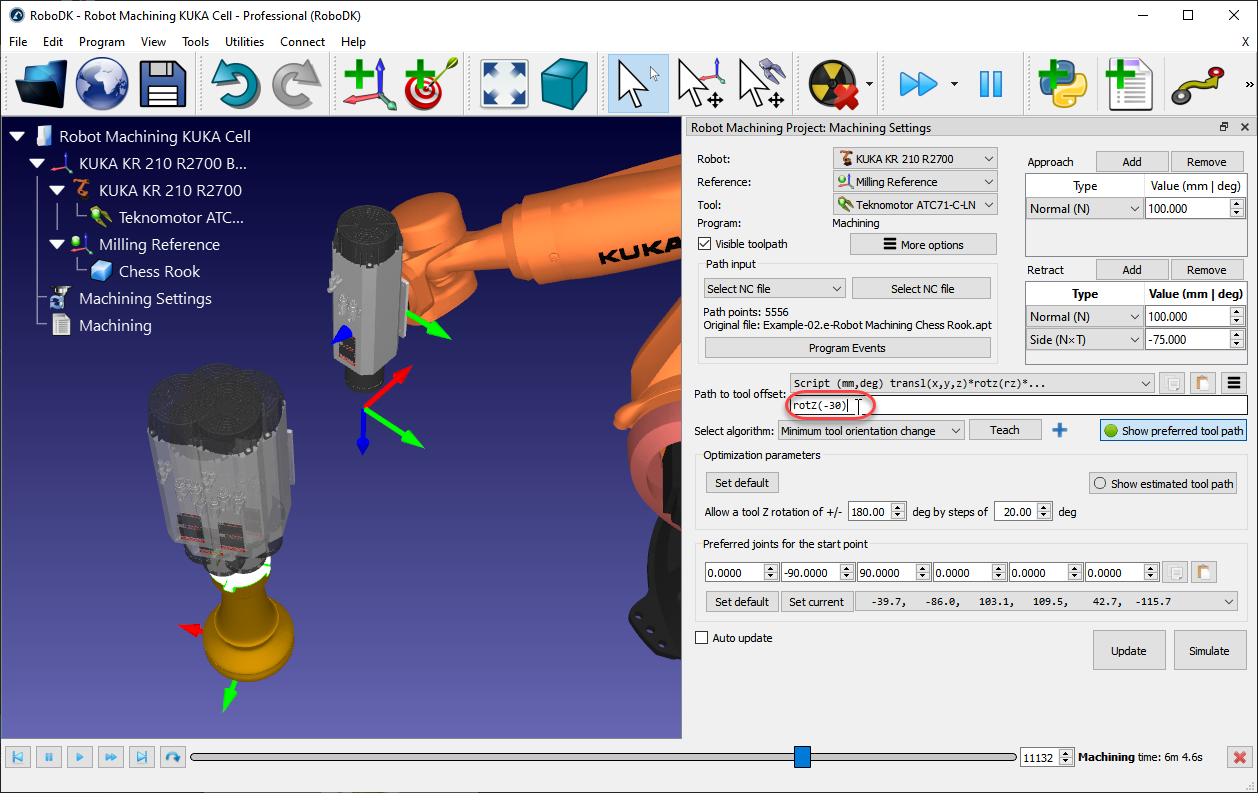

By default, the path to tool offset displays a rotz(0) transformation. This means you can add an additional rotation around the Z axis of the tool. This value can be modified to establish the preferred orientation of the tool, modifying the orientation around the Z axis of the TCP or in combination with other axes. The preferred orientation is the orientation the robot will try to keep while following the toolpath.

By default, RoboDK uses the Minimum tool orientation change algorithm. This means the orientation of the tool is kept as constant as possible along the toolpath. In general, this option is suitable for milling operations as it minimizes robot joint movements. Alternatively, other algorithms/methods are available, such as the tool orientation following the toolpath (useful for cutting applications, where the blade needs to remain tangent along the path), or the robot holding the object if the toolpath needs to be followed attached to the robot tool (for example, for dispensing or polishing applications, also known as Remote TCP configurations).