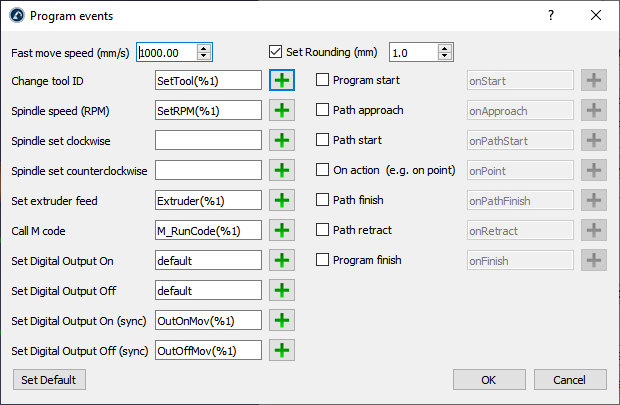

Program Events

Select Program Events to display special events that need to be taken into account when generating robot programs. This includes triggering a tool change, setting the spindle speed in RPM or triggering specific programs on program start or program finish.

You can specify a rounding valuein Program events. This will automatically create a rounding instruction at the beginning of your program and will help making the robot machining programs smoother, preventing the robot to shake. For example, on an ABB robot this will set the ZoneData value in mm, on a Fanuc robot this will set the CNT value as a percentage and on Universal Robots controllers it will set the blending value in mm.

If you are using G-code or NCI files, custom M codes will be triggered by default as function calls to M_RunCode (the M code is passed as a parameter). You can remove the custom M calls by deleting the call to M_RunCode.

Move your mouse cursor over the corresponding field for more information to customize each section.

For example, when changing the tool you can use the %1 value to represent the tool ID provided by your CAM software. If you prefer triggering static functions instead of passing arguments you can replace SetTool(%1) by SetTool%1. When using tool 2, this would generate SetTool2 instead of SetTool(2).