Yaskawa Motoman robots

RoboDK supports all Yaskawa Motoman robot controllers since XRC controllers. You can create JBI program files directly from RoboDK and move the real robot from RoboDK using the driver for Yaskawa Motoman robots.

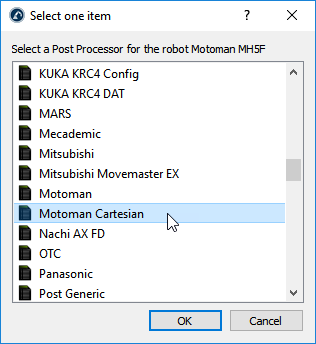

By default, when you generate a JBI program from RoboDK you may see the target output in pulses. Some operations, such as changing the tool from your program (SETTOOL) or editing Cartesian targets (Relative Job) require specific software options. If you want to generate programs using Cartesian coordinates you can change the default driver to Motoman Cartesian.

More information about post processors and how to customize them is available in the post processors section.

RoboDK driver for Yaskawa Motoman

Robot drivers provide an alternative to Offline Programming. With the Yaskawa/Motoman drivers you can move a robot directly from RoboDK as you simulate your program (Online Programming). More information available in the Robot Drivers section.

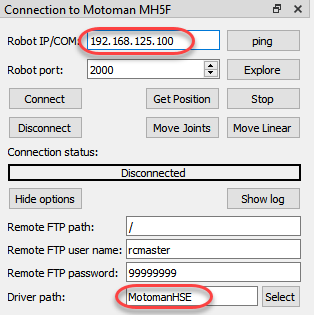

Since RoboDK version 4.2 you can connect to the robot controller using RoboDK’s robot driver using the High-Speed Ethernet Server (HSE) protocol and the driver called MotomanHSE. This driver does not require you to have the MotoCom software option. This communication protocol (also called “Remote”) is available by default with recent Yaskawa robot controllers. This protocol allows you to move and monitor the robot from a computer at a refresh rate of 70 Hz.

Select Connect-Connect to Robot, enter the robot IP and select Connect (you can ignore the port). Make sure you are using the latest driver path that supports HSE protocol (MotomanHSE).

To enable this mode of operation on the robot you should simply set the teach pendant to Remote mode.

This allows using RoboDK’s Run on robot option for online programming and debugging. The connection can be established through a standard Ethernet connection (TCP/IP - UDP).

The configuration should be done automatically and there is no need to set up anything specific on the robot controller side.

The following controllers work with the High-Speed Ethernet Server driver:

●DX100

●DX200

●FS100

●NX100

●YR1000

A connection between RoboDK and any Motoman robot can also be established to move the robot automatically from a connected PC using RoboDK and Motoman’s MotoCom software option and the apimotoman driver.

Update Pulses per degree information

Yaskawa Motoman robots require knowing the ratio of pulses per degree for all robot axes to convert angular joint values to pulses and vice-versa. RoboDK automatically generates programs with the correct pulse information if the pulses per degree ratio is properly provided in the robot parameters.

You can load the ALL.PRM file from your Yaskawa Motoman controller in RoboDK to automatically extract the pulses/degree ratio. The ALL.PRM file should be available when you perform a full controller backup. Following steps demonstrate the procedure to be used in this case:

1.Open your robot in RoboDK.

2.Drag and drop the ALL.PRM file in RoboDK to open it.

3.Accept the changes and you should see the pulses/degree information updated for your robot. You may see a warning message if you didn’t select the correct robot.

4.The pulses/degree information is saved with your RDK project file. You can also save the robot by right clicking on it and selecting Save as… and replace this robot in other projects by right clicking on a robot and select Replace robot.

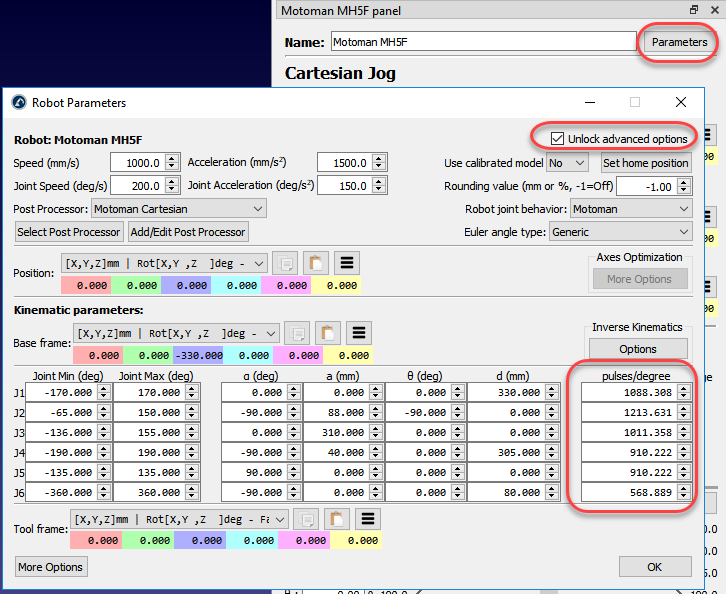

Follow these steps to verify if this information is available for your robot (or to update it):

1.Double click your Yaskawa Motoman robot in RoboDK

2.Select Parameters

3.Select Unlock advanced options

4.Review or update the pulses/degree values for each joint

Once this information is updated you can generate your programs with the correct pulses/degree information.