In a world where digital technology is constantly evolving, it’s no surprise that the way we create art is changing too. Artists have long been at the forefront of new fabrication techniques, having incorporated industrial manufacturing technology since at least the early 1960s.

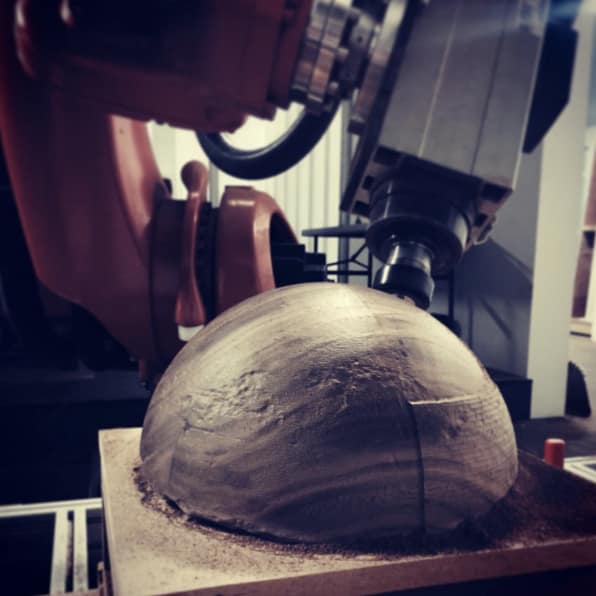

One of the most exciting recent developments in the art world is digital art fabrication, a set of manufacturing processes used to create physical artwork. This includes processes like 3D printing, robot milling, and engraving.

Digital fabrication offers artists a whole new way to create their work, allowing for a previously impossible level of collaboration between artists and industrial fabricators.

Let’s see how one robotic fabrication studio is helping some of the world’s biggest artists and designers to realize their ideas.

About Neoset Designs

Neoset Designs is a digital fabrication firm based in Connecticut, USA. The studio has carved out a niche by focusing almost exclusively on metal additive and subtractive processes using robots. This specialization allows them to handle the fabrication of highly complex parts involving metal, wood, and foam.

The team at Neoset has used RoboDK for years. We have previously reported on their collaborations with Spotify on the music platform’s RapCaviar Pantheon project in 2017, and with artist Robert Longo.

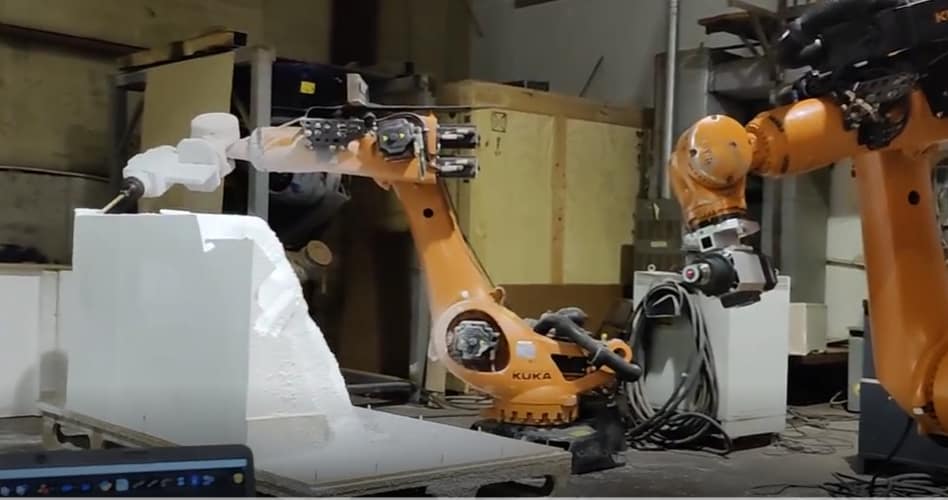

In their studio, they offer a number of robotic fabrication services. These include large-scale robotic manufacturing, metrology-grade 3D scanning, and state-of-the-art laser and camera tracking for adaptive robotic control.

The team has had the privilege of working with some of the world’s most talented artists and designers, including a recent, high-profile project with the fashion designer Louis Vuitton.

Add the video showing Robot Calibration at Neoset Designs:

What Is Digital Fabrication and How Does it Work

Digital art fabrication is the process of creating 3D objects from digital designs for artistic purposes. Unlike industrial manufacturing, where productivity and strict accuracy are the main goals, artists are often more interested in the expressive nature of their fabrications.

As with manufacturing, the process for most digital fabrications starts with a CAD file created by the artist. With robotic milling, fabricators then send this to the robot, which uses a series of cutting tools to carve the object out of a block of material.

One reason artists are drawn to robotic fabrication is the high degree of flexibility it offers. Indeed, this precision and the robot’s large workspace allow artists to create complex shapes and forms that would be difficult or impossible to achieve using traditional methods.

An Incredible Collaboration: Neoset and Louis Vuitton

Neoset collaborates with some of the world’s most iconic and pioneering brands and artists. A standout recent collaboration was with Louis Vuitton.

Louis Vuitton is a world-famous fashion house, known for its luxurious and high-quality products. For their collaboration, Neoset created a set of five massive statues that were shown in Miami, USA, for the company’s Art Basel LVMH Show.

In this case, the team used robotic milling to create the sculptures out of foam. On the day that they were installed, the artistic director of the company, Virgil Abloh, passed away. One of the sculptures was of Abloh. As a result, the installation became a moving tribute to this talented artist.

How Neoset Designs Uses RoboDK for Robotic Digital Art Fabrication

Conventional robot programming would make this type of robotic artwork creation very complex. However, the team at Neoset has removed much of this complexity by using RoboDK.

A key aspect of Neoset’s workflow is using RoboDK as a process controller. This allows the team to implement custom logic for their advanced additive processes—something that would be too cumbersome or unrealistic to perform directly in the KUKA controller. This advanced control is crucial for the hybrid additive-subtractive methods they specialize in.

RoboDK has been the catalyst that gives us confidence to step forward when proposals for difficult projects come to our door. From the platform’s flexibility that makes customization nearly effortless, to the calibration package that provides a user-friendly pathway to dramatically improving system accuracy and reliability, RoboDK gives us the competitive edge we need to thrive in a market that only rewards the best-prepared players. But what I personally love about the product is its value as an educational tool—one I can use with every newcomer to help them quickly and effectively learn about robots in a way that’s perfectly aligned with how robots operate in the field.

CEO at Neoset Designs

Neoset has fully automated the production workflow using RoboDK’s API by using custom Python scripts to produce and refine all the required robot toolpaths to fabricate each unique piece..

RoboDK makes programming for digital art far more accessible than it was in the past. The team can directly load and process the CAD files for the artwork into RoboDK’s offline programming environment. RoboDK’s machining wizard can then output code for a variety of robotic manipulators.

This simplicity and flexibility allow the team to focus on the most important part of robotic art fabrication—ensuring that the resulting art pieces fully reflect the design and vision of the artists.

The Future of Digital Art Fabrication

Surely, Neoset’s project with Louis Vuitton is just the latest in the company’s growing catalog of exciting artistic projects.

Both the artists and RoboDK believe that digital fabrication techniques like robot milling can create unique and innovative works of art. As more artists begin to see the possibilities of the technology, we expect to see more projects like these.

After all, we are looking forward to seeing what Neoset Designs does next with RoboDK!

What do you think of robot-created artworks? Join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.. Also, check out our extensive video collection and subscribe to the RoboDK YouTube Channel