Comau is a global leader in advanced automation and robotics, combining over 50 years of experience with a complete portfolio of high-performance industrial and collaborative robots.

As both a system integrator and a robotics manufacturer, Comau has been shaping the evolution of industrial automation since its origins in the automotive sector, where we integrated complex production lines powered by hundreds of robots and designed to build thousands of vehicles.

Today, we bring the same engineering excellence to a wide range of traditional and emerging industries, including those operating in unstructured environments. Our approach goes beyond technical expertise: it is rooted in innovation, passion, and the ability to transform automation challenges into efficient, future-ready solutions.

Who Are Comau?

Founded in Turin, Italy, Comau is a global leader in automation solutions. With a comprehensive robot portfolio known for reliability, precision, and cost-effective performance, Comau continues to push the boundaries of what robotics can achieve. This is why the partnership with RoboDK is centered around robotics at its core. Together, they enable users to simulate, program, and deploy Comau robots more efficiently than ever—accelerating integration workflows and unlocking new levels of flexibility for both newcomers and automation experts. From simulation to real-world deployment, Comau and RoboDK provide a powerful, end-to-end ecosystem for robotic programming and advanced automation.

Common Applications for Comau Robots

Comau robots are found across many diverse businesses and sectors. From the company’s defining role Comau robots are found across many diverse businesses and sectors. From the company’s defining role in automotive manufacturing, it now serves a wide range of industries.

Some common application areas include:

- Logistics Automation — With Automha, Comau significantly enhances its offering of high-performance and scalable solutions, reconfirming and strengthening its Italian roots and operations.

- Food and Beverage Packaging — Robots like the Racer-5 are especially suited to sensitive environments, enabling hygienic handling and packaging of foodstuffs.

- Pharmaceutical Production — Strict contamination controls are also applicable for pharmaceutical manufacturing, and Comau has solutions specially designed for cleanroom environments.

- Renewable Energy Manufacturing — Comau continues to build on its foundational robotic application by bringing its automated assembly expertise into tasks like solar panel installation and hydrogen fuel cell production.

- Shipbuilding and Heavy Industry — With integrated solutions for [robotic welding][MR4WELD], Comau enables automated welding and inspection of large steel structures suited to marine environments.

With such applications, Comau robots are helping many businesses transform their complex production environments to be faster, more flexible, and more consistent.

Programming Your Comau Robot: The 3 Core Options

With the recent collaboration between RoboDK and Comau, programming a Comau robot has never been easier.

Whatever programming solution you choose, the most important thing is picking one that suits your application and level of expertise.

Here are the 3 core options for programming Comau robots:

1. PDL2 Language (Native Programming)

Most industrial robot brands have their own proprietary programming language, and Comau is no different.

The PDL2 language is the traditional method for programming the company’s industrial robots. This text-based programming language is similar in syntax to Pascal with extra functions to control robotic manipulators.

Programs in PDL2 can be created on the robot’s teach pendant (such as theTP5) or on a computer using Roboshop .

2. TPX Teach Pendant with Easy Prog

Teach pendants have been a cornerstone of industrial robotic programming for decades… But they have changed little in all that time.

Comau’s recent addition changes that with their TPX, a teach pendant with added graphical features. The pendant includes a basic 3D simulator to visualize the robot. It also includes the company’s Easy Prog feature, which allows for visual programming without requiring knowledge of PDL2.

3. RoboDK: Simplifying Comau Robot Programming

If you want to really streamline your robot programming, RoboDK and our partnership with Comau provides a perfect solution.

RoboDK provides a flexible way to program, simulate, and deploy Comau robots offline.

By integrating RoboDK into your setup, you gain:

- CAD/CAM Integration — You can import tool paths directly from your preferred design software and export them directly to your Comau robot.

- Offline Simulation — Simulation allows you to validate trajectories, test the robot for reachability, and avoid collisions. Offline programming helps to reduce deployment time without needing to take the physical robot out of production.

- Post-Processing and Direct Control for Comau — With our Comau post processors, RoboDK automatically generates PDL2 robot programs with correct syntax and motion logic. You can even use the real-time drivers to test and fine-tune your programs live on the physical Comau robots.

Spotlight on 3 Comau Robots in the RoboDK Library

Our Robot Library supports over 1,200 robot models from 80+ brands, including a comprehensive range of Comau robots.

Here are 3 featured robots you can find in the library:

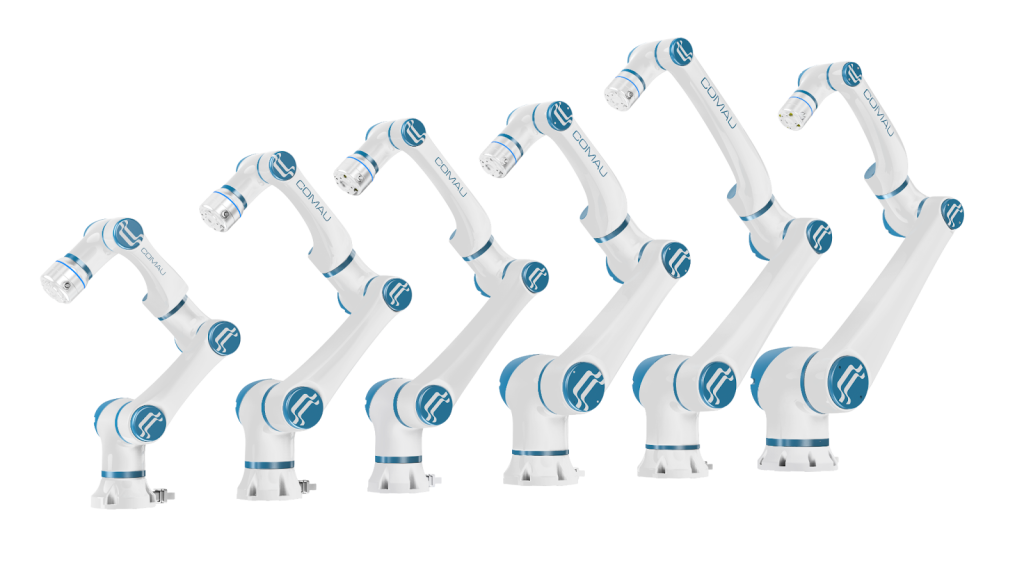

1. MyCo Family

In recent years, Comau’s range of collaborative robots has grown significantly, with its newest MyCo range being the latest.

The MyCo Cobots family delivers a versatile set of lightweight, easy-to-install collaborative robots (payload 3–15 kg, reach 590–1300 mm) designed for fast integration, high precision, flexible redeployment and safe human-robot collaboration in a wide range of industrial applications.

2. S-Family and Comau N220

Introducing the S-Family: a new generation of small robots designed to meet the diverse automation needs of customers in General Industry sectors. Developed by Comau, a leading industrial automation provider, the S-Family combines traditional expertise with cutting-edge technologies to provide exceptional performance and accuracy.

The robot offers a 13 kg payload with a maximum reach of 1960 mm, and an 18 kg payload with a maximum reach of 1730 mm. Both ensuring excellent cycle time, repeatability, and path-control accuracy.

The Comau N220 is one of the company’s core industrial robots, offering 220 kg payload capacity and an impressive 2.67 m reach.

Designed for tasks like machining, heavy handling, and engraving, the robot also comes in a ceiling-mounted variant in our Robot Library. The N-220-2.6-ceiling allowing for even more applications.

3. Comau e.DO

The Comau e.DO is a 6-axis educational robot designed for learning, research, and prototyping. It is widely used in schools to teach technology, mathematics, and physics.

The company also provides a range of supporting educational materials to facilitate learning, including activity cards, training packages, and interactive apps.

Getting Started with RoboDK for Comau Robots

Getting started with Comau robot programming in RoboDK is quick and simple:

- Download and install RoboDK.

- Search for your Comau model in the Robot Library and load it.

- Create, simulate, and export your program directly to the robot controller.

- Test the program offline or connect live using RoboDK’s real-time drivers.

RoboDK provides a powerful workflow for both industrial automation and many other applications. With full support for Comau’s ecosystem, RoboDK is the perfect partner for the company’s extensive range of robots.’s ecosystem. RoboDK is the perfect partner for the company’s extensive range of robots.

What will be your first application with your Comau robot? Join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.. Also, check out our extensive video collection and subscribe to the RoboDK YouTube Channel