What’s the best place to discover the latest developments in the robotics industry? For many, it’s the Automatica trade fair in Germany. Here’s what we learned at RoboDK during this year’s Automatica 2025!

Automatica is held every two years in Munich, Germany. As Europe’s leading trade fair for automation and robotics, it is one of the best places to connect with robotics companies and users from all over the globe.

The 2025 edition was one of the most vibrant in recent years. RoboDK was there on the ground to explore the latest developments.

Let’s have a look at the trade fair and what we learned this year…

Setting the Stage at Automatica 2025

Every two years, the world’s biggest and most innovative technology companies converge on the giant Messe München conference center in Munich, Germany.

The center hosts multiple key industry trade shows concurrently, which this year included the SicherheitsExpo security fair, World of Quantum technology fair, and Laser World of Photonics fair.

For robotics, the primary show of interest is Automatica.

Automatica is the largest trade fair for robotics and automation in Europe. This year, it was visited by over 49,300 people from more than 90 countries. This included 800 exhibitors and over 1,100 robots on display.

At RoboDK, we explored the trade fair halls to bring you the best and most interesting developments from this year’s event.

Introducing Comau: Democratizing Advanced Robotics

Comau is a world-leading provider of robotic solutions with over half a century of experience in industrial robotics. The company boasts an impressive track record of industry-leading solutions, including the groundbreaking collaborative AURA cobot with 170 kg payload capacity that it launched in 2020.

This year, we caught up with Gioacchino Civiletti, Product Manager at Comau at their booth in Hall B5, who showed us the company’s latest collaborative robots in their MyCo range.

Cobots for Many Applications

The company’s MyCo cobot range covers payloads from 3 to 15 kg. They are suitable for a wide range of applications including arc welding, pick and place, palletizing, and even educational use.

A significant benefit of Comau’s new cobots is how they can help to optimize floor space. Through a combination of technology, training, and after-sales support, they help new users to benefit from the company’s wide expertise.

You can find the MyCo robot models ready for use in RoboDK in our Robot Library

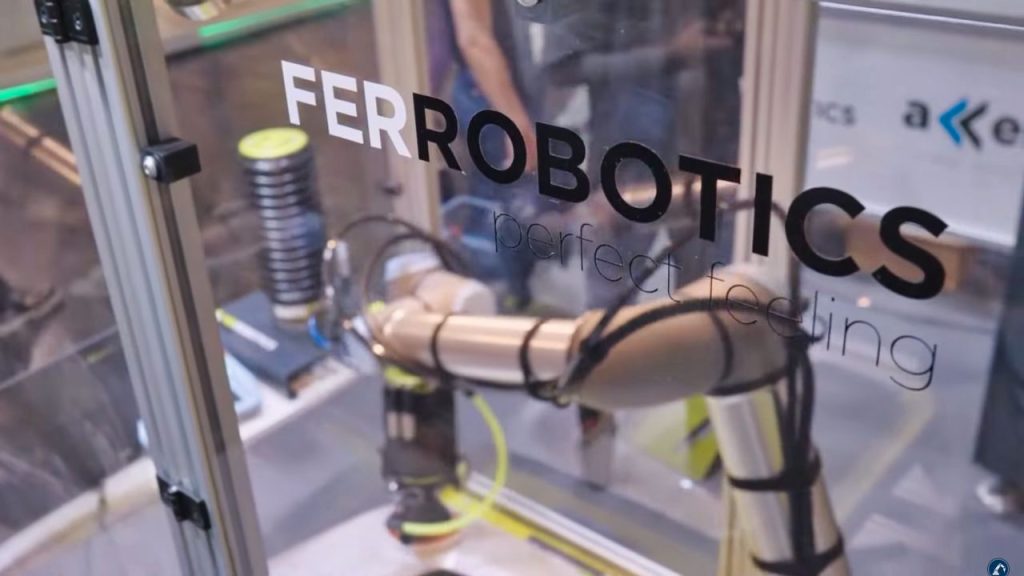

Introducing FerRobotics: Giving Robots the Sense of Touch

FerRobotics is an Austria-based company specializing in sensitive products for grinding, sanding and other surface finishing processes.

Many of our RoboDK users employ FerRobotics tools in our simulator. We spoke to Ronald Naderer, CEO of FerRobotics, at the company’s booth in Hall B6 about the benefits of using their system when moving from a CAD system to a real robotic process.

Solving the Challenge of Force Control in CAD

As a global leader in Active Compliant Technology, FerRobotics equips cobots with what they call “contact intelligence”. This helps to address a common issue with robotic surface finishing — while the CAD file can generate trajectories for the surface passes, you can’t see process parameters like force or RPM of the tool.

Naderer explained:

“Robotic sanding and grinding is one of the most complicated processes to simulate. You can see the robot movement, but you cannot see the force. We have a very good experience using RoboDK because we can simulate the whole process.”

Introducing Autonox: Redefining Robot Mechanics for Robust Machining

Autonox is a provider of controller-independent robotic mechanics that supports a wide range of robotic structures and specifications.

As many RoboDK users employ our software for robotic machining, we were interested to learn from Autonox’s expertise.

We spoke to Elisabeth Schärtl from Autonox at the company’s booth in Hall A4.

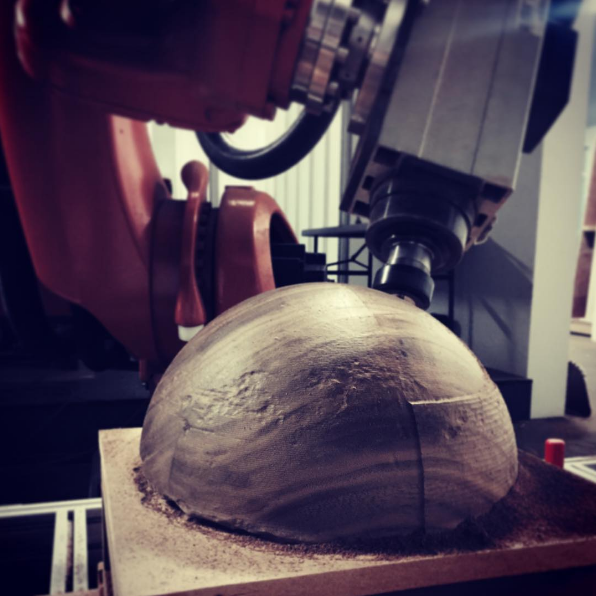

The First Robotic Machining of Tempered Steel

One application that the company had on show was developed in collaboration with Siemens and Fraunhofer IFAM. It combines the concept of CNC control with specialized damping features to create a high-stiffness robotic hardware.

This makes the system suitable for milling very hard materials like tempered steel, which was not possible previously with robotic machining.

Schärtl explained:

“Of course, it is not in competition with classic CNC machining. It is still a robot. But you now have the possibility to machine bigger parts with a precision that has not been possible with a robot until now.”

The exact path accuracy of the milling process varies depending on the specific application and materials. However, the company is already achieving very promising accuracies, with even more developments expected in the future.

Looking Ahead: What Automatica 2025 Tells Us About Robotics

This year’s Automatica underscored a major theme in robotics, where technologies are used in connected ecosystems instead of isolated systems. From Comau’s new cobot range to the application-specific developments of FerRobotics and Autonox, we are seeing solutions that push the boundaries of what is possible with robotic automation.

Takayuki Ito, President of the International Federation of Robotics, said in a summary of the trade fair “Automatica is one of the most important events for the entire European robotics industry. It brings together global technology leaders and users to exchange ideas, explore innovations, and drive the future of automation.”

At RoboDK, we believe in creating solutions that bring different technologies together to make life easier for robot users. This means continuing to connect with companies that are pushing the boundaries of what is possible with robotic automation.

We are already looking forward to the next Automatica in 2027, to see what fresh developments are just around the corner!

What trends in robotics are you noticing this year? Join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.. Also, check out our extensive video collection and subscribe to the RoboDK YouTube Channel