In the nuclear industry, robots are more than just automated tools — they are an extension of human arms, allowing people to operate in hazardous radioactive environments. Here is how the ORANO robotics group used RoboDK to validate their digital twin for nuclear teleoperation.

Teleoperation involves controlling the robot remotely from a safe location. The operator often has only visual feedback of the remote environment from cameras and sensors, sometimes with haptic force feedback. This limited view of the robot can introduce difficulties when judging movements, causing collisions or task errors.

This is exactly the challenge that ORANO, a global leader in nuclear mining, enrichment, fuel recycling and dismantling services, set out to solve with RoboDK.

Here’s how they approached the project…

Introducing… ORANO Robotics

Orano is an internationally recognized expert in the nuclear fuel cycle. The company develops pioneering solutions to enhance safety, efficiency, and precision in complex nuclear operations.

Orano Robotics specializes in cutting-edge technology for nuclear decommissioning, inspection, and maintenance. Their systems include mobile robotics, manipulators, and other robotic hardware to address diverse challenges in the nuclear industry.

For this project, the team was looking for a way to tackle a common problem for nuclear teleoperation. Lack of visibility of the physical robot.

The Challenge: Seeing What the Operator Can’t

Teleoperation is a form of robotics where a human operator is part of the control system. In other words, the human controls the robot remotely.

This human-in-the-loop type of robotics is necessary in hazardous environments that are inaccessible to human workers. In the nuclear industry, high levels of radiation mean that hands-on operation and maintenance is impossible. Tasks are too complex or unpredictable for full automation, so the only reliable solution is to control the robot remotely.

However, teleoperation comes with a unique set of challenges.

Traditional setups rely heavily on camera systems to give visual feedback to operators. These offer only a restricted view of the workspace, and video feeds are prone to latency. Without a direct line of sight to the robot, the operator can’t see exactly how the robot is moving at any given moment.

This means that operators require high skill to complete any tasks with the robot. Even skilled operators may struggle to judge distances and orientations precisely. A single misjudged movement can cause tool damage or collisions with the environment.

The Solution: Building a Real-Time Digital Twin with RoboDK

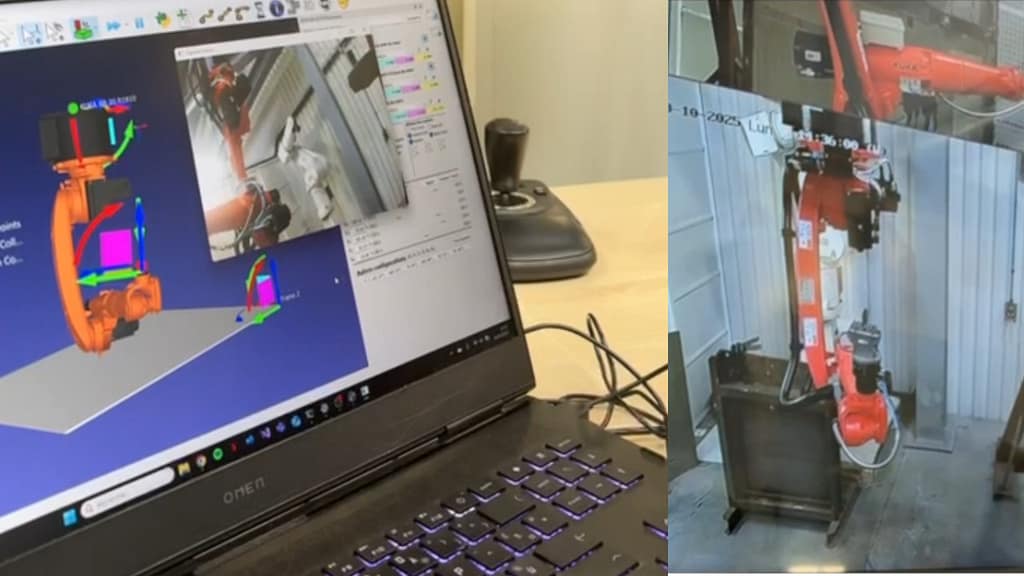

The team at Orano proposed a solution that harnesses the power of RoboDK with a real-time digital twin into their existing Human-Machine Interface (HMI).

Ndiaye Hamedine, an engineer at Orano, explained:

“Our goal was to provide a clear HMI to the operator showing the robot’s position in its environment, while managing functional safeguards and being independent from the robot manufacturer.”

The system uses a virtual model of the robot in a simulated environment that is continually updated with real-time data from the physical robot. The operator can then see the robot moving in the simulation, providing extra information about its position and orientation besides the live camera feeds.

Some key features they used included:

- Accurate 3D Workspace Modeling — The team imported STEP files of the remote workspace and the KUKA robot to ensure that the important aspects of the system were represented accurately.

- Live Joint Position Retrieval — RoboDK’s real-time capability allowed for a two-way data flow between the simulation and KUKA controller. Joint angles were retrieved from the controller and translated into live motion in the simulation.

- Collision Detection — Built-in collision detection in RoboDK allowed the operator to monitor the robot fully in the virtual workspace and avoid collisions in the real environment.

Hamedine says:

“RoboDK enabled us to validate a digital twin for a KUKA robot with real-time synchronization between the physical and simulated systems, demonstrating the feasibility of hybrid supervision in an industrial context.”

The System: Hardware and Software

To create this teleoperation system, the team at Orano combined off-the-shelf automation components with powerful robot programming software and custom scripts.

Hardware components include:

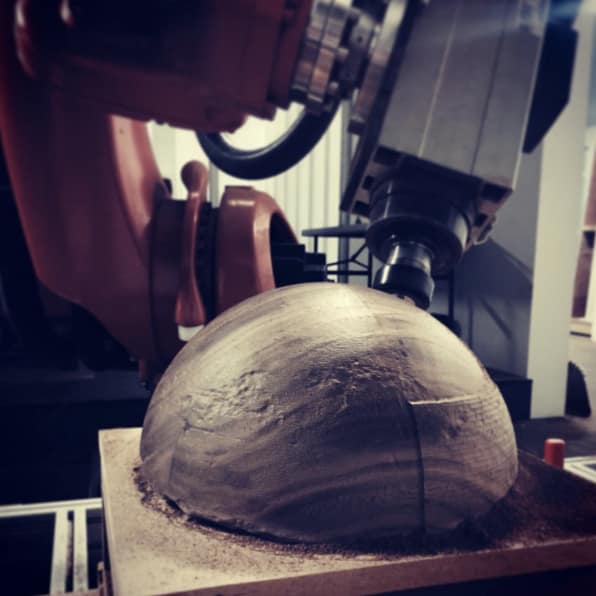

- KUKA KR20 R1810 robot — This 6-axis industrial manipulator provides sufficient repeatability and high stiffness to be suitable for remote handling in nuclear applications.

- KUKA controller — The robot’s controller handles both the teleoperated commands sent by the system’s Human-Machine Interface and the real-time joint positions that are sent to the simulation in RoboDK.

- IP camera — This camera sensor captures additional visual feedback from the workspace for real-time operation and for recording and verification.

Software components include:

- RoboDK — The RoboDK graphical environment provides real-time visualization, digital twin modeling, and collision detection to help the operator.

- Python scripts — These custom programs execute the team’s control logic and facilitate communication between the KUKA controller and RoboDK.

- OBS Studio — OBS Studio serves as a software bridge. Since RoboDK natively supports only USB cameras, OBS is used to convert the IP stream into a virtual webcam.

This modular combination of components ensures that the system is flexible and easily extensible for future software developments.

The Results: Safer, Smarter Teleoperation

With this system, the team built a fully functional teleoperation system that combines visual feedback with a digital twin. This combination allows operators to perform tasks in radioactive environments even when they don’t have direct visual access to the robot.

The digital twin created in RoboDK provides a clear representation of the robot’s position in its environment, helping to ensure safe and accurate manipulation. This allows the operator to monitor the physical movements. Even when the robot is completely hidden, proactively detect collisions, and operate more efficiently while minimizing guesswork.

After the success of this validation project, the team at Orano aims to further build on the digital twin with teleoperation concept to applications where robust collision avoidance is critical. These may include inspection, maintenance, and handling tasks.

What challenges could you solve by creating a digital twin? Join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.. Also, check out our extensive video collection and subscribe to the RoboDK YouTube Channel