In the rapidly evolving landscape of robotics, one technology stands out as a game-changer: Digital Twins. These virtual replicas of real-world objects and processes have revolutionized robotic programming, offering a myriad of benefits that go beyond mere simulation.

In this article, let’s delve into the world of Digital Twins and explore how they are reshaping offline programming, ensuring precision, safety, and efficiency in robotic applications.

Defining Digital Twins

Before we dive into the advantages, let’s demystify Digital Twins. They are sophisticated virtual models that simulate the behavior and characteristics of physical entities, be it a robot or an entire production line. These twins are not mere static replicas but dynamic simulations capable of mimicking real-world scenarios with remarkable accuracy.

One of the significant advantages of Digital Twins in robotic programming is the ability to safely visualize and test various scenarios in a controlled and accurate virtual environment before implementing them in the real world.

Digital Twins in robotic programming can be understood through two primary lenses:

1. Modelling and Simulation: A Secure Rehearsal Space

Modelling and Simulation represent offline programming where code is generated from a virtual model without real-time interactions. It acts as a secure rehearsal space for robots.

2. Real-time Monitoring: Bridging the Virtual-Real Divide

Real-time Monitoring, with tools like TwinBox, enables online communication, allowing immediate feedback between the real and virtual robots.

Benefits of Digital Twins

Digital Twins are pivotal in optimizing offline robotic programming, offering opportunities for innovations, safety, and accuracy in visualizations and applications. By leveraging the potential of Digital Twins, industries can stay ahead in the competitive landscape. They can navigate complex systems with enhanced insights and reliability. The future promises substantial opportunities for advancements and applications of Digital Twin technology in robotic programming. Driving industries towards unprecedented levels of operational efficiency and excellence, Digital Twins also allow programmers and operators to identify potential issues, optimize robot performance, and safeguard both the robot and its environment. Such foresight is vital to prevent expensive errors and system downtime, enhancing the reliability of robotic systems. Furthermore, the improved accuracy of these simulations minimizes the need for fine-tuning paths.

The amalgamation of rich data and detailed simulations empowers engineers and programmers to innovate and enhance robotic applications. The interaction between virtual and real-world data provides profound insights. Improving operational efficiency, enabling predictive maintenance, optimizing resource allocation, and fostering the development of innovative solutions, ultimately enhancing product quality and customer satisfaction.

Transition to the Real World

Builders can create precise virtual models of real robotic cells, enabling them to make necessary adjustments directly in this environment before implementing them on the robot. This ensures synchronization and a seamless transition between the simulated and real worlds. The precision in adjustment and direct communication between the digital twin and the actual robot ensures that every concept developed within the simulation can be accurately translated into the real world, allowing for real-time interaction and consistency.

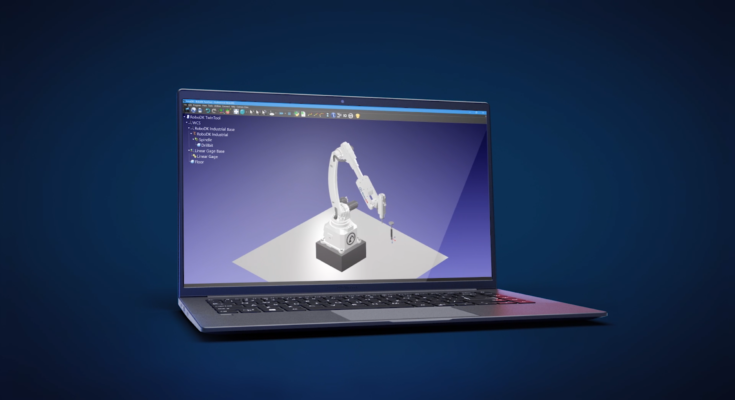

RoboDK software is at the forefront of exploiting Digital Twins for detailed simulation and offline programming of robots. Facilitating the simulation of complex structures, from entire factory layouts to individual cells, right from a computer. The software also allows for the seamless creation of comprehensible instructions. Ensuring accurate replication of simulations on robots, thus mitigating risks, and promoting safety by providing a platform for testing and visualizing different situations.

Conclusion: the Future of Robotic Programming

In conclusion, Digital Twins are pivotal in optimizing offline robotic programming. Industries that leverage this technology gain a competitive edge by navigating complex systems with enhanced insights and reliability. As we look ahead, the future promises even greater opportunities for advancements and applications of Digital Twin technology. Driving industries toward unprecedented levels of operational efficiency and excellence.

Ready to harness the power of Digital Twins with RoboDK? Take the first step towards revolutionizing your robotic programming and visualization processes today. Download RoboDK’s Trial License to learn more and start your journey towards enhanced robotic programming.

What questions do you have about Digital Twins? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum. Also, check out our extensive video collection and subscribe to the RoboDK YouTube Channel.