In the world of automation and manufacturing, industrial robots stand as a testament to human ingenuity and technological advancement. These sophisticated machines have revolutionized the way industries operate. But as industrial robots become an integral part of modern manufacturing, ensuring their safe and efficient operation is of paramount importance. Collision avoidance, in particular, emerges as a central concern, given the potential risks associated with unintended robot movements in densely populated factory floors.

While the aim is straightforward—preventing robots from making unintended contact with objects, other robots, or humans—the implementation has some complexities. Unlike controlled laboratory settings, factory floors are dynamic. Workers move about, new objects are introduced, and other robots shift positions. Predicting every possible movement in such an ever-changing environment is a daunting task.

Sensors

Traditional robots often rely on a limited set of sensors, which might not capture the entire scope of their surroundings. Blind spots can lead to miscalculations, increasing the risk of collisions. And industrial robots come in various shapes and sizes, each with its own set of moving parts. Humans don’t move with the predictability of machines. They might change directions abruptly or make unexpected gestures, making it challenging for robots to anticipate and avoid collisions.

Collision Avoidance in Dynamic Environments: The Role of AI in Industrial Robotics

Data processing

So, collision avoidance requires real-time data processing. Any lag in processing sensory input or in executing a response can lead to mishaps, especially when robots operate at high speeds. In settings where multiple robots work in tandem, effective communication is crucial. A failure in relaying positional data or intended movement can result in two robots inadvertently moving into each other’s paths.

Complex environments

Consequently, as robots navigate complex environments, they rely on a myriad of sensors to understand their surroundings. Cameras capture visual data, lidar measures distances with laser light, and ultrasonic sensors detect obstacles through sound waves. AI excels in merging these multi-modal data streams to form a comprehensive, real-time view of the environment—a process known as sensor fusion.

Learning

By integrating diverse sensory inputs, AI ensures that robots have a holistic understanding of their surroundings, reducing blind spots and enhancing decision-making. And in the fast-paced world of industrial robotics, decisions need to be made in the blink of an eye. AI’s prowess in rapidly processing vast amounts of data ensures that robots can make split-second decisions, be it a sudden stop or a change in direction.

The true strength of AI lies in its ability to learn and adapt. As robots encounter new scenarios or challenges, AI algorithms refine their strategies, ensuring better outcomes in the future. This continuous cycle of learning and updating is vital for robots to remain effective and safe in ever-evolving industrial settings.

Experience the Power of Smart Robots with RoboDK

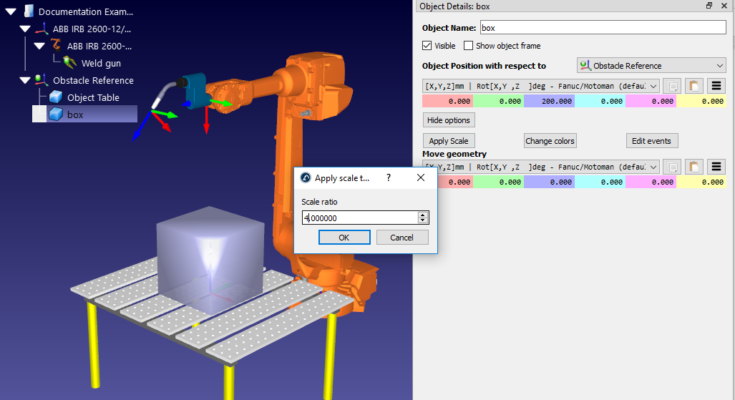

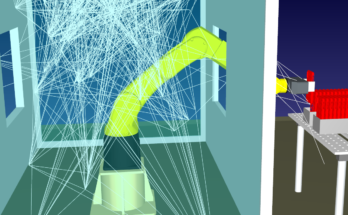

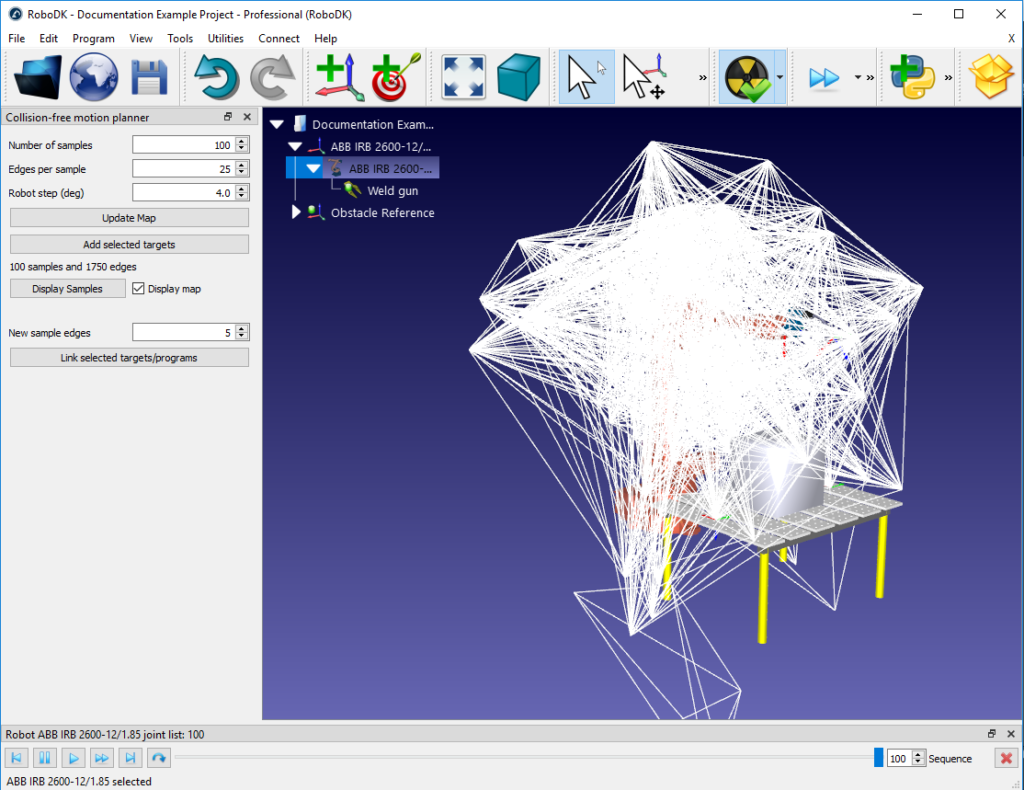

Collision checking with RoboDK can help you prevent collisions in your real setup. Can be used in different ways such as visually checking collisions, automatically avoid collisions for robot machining projects or generate a collision-free map to automatically create collision-free programs.

Learn more about Collision avoidance with RoboDK in our Documentation such us how to Setup for Motion Planning.

What questions do you have about smart robots? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum. Also, check out our extensive video collection and subscribe to the RoboDK YouTube Channel.