The days of fully automated or fully manual manufacturing are over. Human-robot collaboration is already becoming a rising star in manufacturing.

But, there are still challenges to getting that collaboration right. Humans are inherently unpredictable, while robotic systems require predictability.

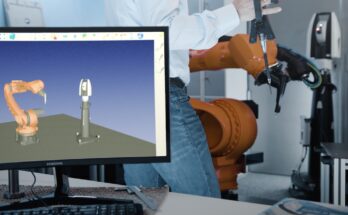

Researchers from the Université du Québec à Chicoutimi show how RoboDK can break down the barriers between robots and humans.

The project explored disassembly battery packs for the Nissan Leaf electric car. It showcases how RoboDK can be used for streamlining production schedules, while remaining flexible to changing demands and working procedures.

Heres how the researchers applied some well-known planning approaches to this automotive application.

The Challenge of Unpredictable Humans

We humans are unpredictable creatures. We respond to many changing factors in our environment, often in surprising ways.

This unpredictability makes humans very flexible to unexpected changes… but it can also be very problematic for human-robot collaboration.

The researchers, part of the Laboratoire d’Automatique et de Robotique interactive (LAR.i), started by exploring how previous researchers had tackled this problem.

When performing a task like battery disassembly, a robotic system needs to schedule its task. But it also needs to account for the human’s unpredictable actions.

Ways that researchers have tried to deal with human unpredictability include:

- Static Allocation — Some researchers try to define the human behavior statically. They model humans as predictable and rigid, though this doesn’t reflect reality.

- Online Scheduling — Some systems account for unexpected changes by performing on-the-fly scheduling. This allows the system to update when the human makes an unplanned action.

- Human Factors Planning — Some researchers have gone even further and incorporated advanced models of human behavior into the system. These include factors like the human’s fatigue over time, experience with the task, physical ergonomics, and varying trust towards the robot.

These approaches all attempt to harmonize the capabilities of both humans and robots in a shared workspace.

The Project: Nissan Leaf Disassembly

The Nissan Leaf is an electric car designed to be eco-friendly while still including advanced features for safety and convenience. With the Leaf, Nissan says it aims to combine sustainability, technology, and practicality.

The research project by researchers at LAR.i centers on the disassembly of battery packs for the Nissan Leaf. This is a core step in the recycling of these batteries and thus contributes significantly to the car’s sustainability.

A challenge with these battery packs is that disassembly involves some complex steps. These can’t be carried out by robots alone — they need human intervention.

The disassembly process involves steps including unscrewing, detaching of wires and cables, and storing battery components. Robots are capable of performing some of these alone, but some are too intricate.

The Traveling Salesman Problem

A core part of the human-robot system was the need to reschedule planning to respond to changes from the human worker.

The researchers decided to formulate this problem using The Traveling Salesman Problem, a classic formulation for algorithmic planning.

The Traveling Salesman Problem involves finding the shortest possible route for a salesperson to take when traveling between a list of cities. It is used for a variety of problems in computer science, most notably for logistics and delivery applications.

In this research, the human-robot collaboration used this approach to plan the optimal task sequence for the battery disassembly. To do this, they combined it with the Knapsack Problem, a planning problem for resource allocation.

For a detailed description of how the researchers achieved this, read their published paper on the project.

The 3 Phases of the Robotic System

The system was split into 3 distinct phases, each taking a different part of the planning for the Nissan Leaf battery pack.

These 3 phases were:

- Offline Planning Phase — The system begins with the offline planning step, which used RoboDK for simulation. This phase included predictive analytics to plan for expected human behavior during the disassembly task.

- Online Adaptation Mechanism — At the heart of the system is a dynamic feature designed to monitor and adjust to the human worker’s real-time performance. This adjusts the robot’s tasks on-the-fly to align more accurately with the human.

- Human Variability and Error Correction — The system also includes a sophisticated error correction module to respond to unpredictable human actions.

Together, these 3 phases allow the robotic system to get the best of both worlds by combining offline planning with online rescheduling.

How the Team Used RoboDK

RoboDK’s critical role in the project was to bridge the gap between simulation and real-world execution. For this, the researchers used it in both the offline planning and operational phases of the task.

The team used RoboDK’s powerful Python interface to develop the planning algorithm.

By simulating the execution of tasks, the team could assign a quantifiable cost to each task in the disassembly process. RoboDK’s cycle time estimation allowed them to calculate an expected time for each task during the planning phase. This also gave the researchers valuable insights for optimizing the task offline.

The simulation’s high accuracy ensured that the transition from offline planning to real-world operation was seamless.

Advancing Human-Robot Collaboration

With the rise of collaborative robotics, it seems likely that there will be an increased need for systems for robust human-robot interaction.

Projects like this one show how useful RoboDK can be in providing a bridge between theoretical planning of tasks and practical execution. The software allowed the researchers to create a system that seamlessly jumped between the controlled simulation and messy real-world.

We look forward to seeing even more projects like this.

What tasks do you perform that would require human-robot collaboration? Join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.. Also, check out our extensive video collection and subscribe to the RoboDK YouTube Channel