12-13-2022, 08:26 PM

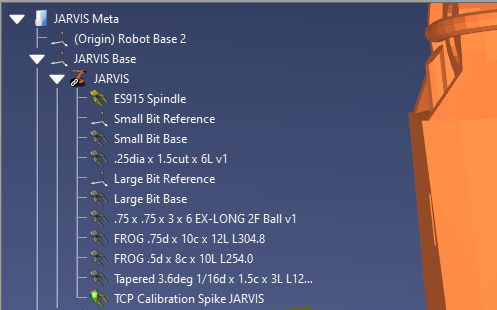

Having the ability to make folders for different tools would be a great way to keep things organized for a milling/machining robot. This is just a small and developing list of tools, but it would be great to make "Flat," "tapered," "ball," etc folders to organize the tools and de-clutter the tree a little bit.

The advantage of this vs exporting different tools into a library to import later is simply speed and efficiency.

Having all of the tools preloaded into the workstation, just organized by folders makes for quick tool assignment for tool path programming. I use Fusion360, as well as Vectric Aspire to generate toolpaths. While Fusion360 can export tool data into RoboDk via add-on, Aspire does not have the proper post-processors or add-ons to do that. So toolpaths get generated in Aspire and uploaded into RoboDK as G-Code, then turned into Python with appropriate TCP configurations for our Kuka KRC2 to process.

Thanks.

The advantage of this vs exporting different tools into a library to import later is simply speed and efficiency.

Having all of the tools preloaded into the workstation, just organized by folders makes for quick tool assignment for tool path programming. I use Fusion360, as well as Vectric Aspire to generate toolpaths. While Fusion360 can export tool data into RoboDk via add-on, Aspire does not have the proper post-processors or add-ons to do that. So toolpaths get generated in Aspire and uploaded into RoboDK as G-Code, then turned into Python with appropriate TCP configurations for our Kuka KRC2 to process.

Thanks.