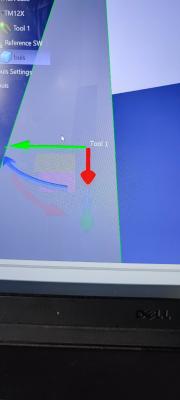

I am trying to let my robot follow the outer edges of a metal part. When simulating the path in RoboDk offline, the path (green line) is followed exactly. After connecting to the robot, the path is not followed exactly anymore. For example on this straight section:

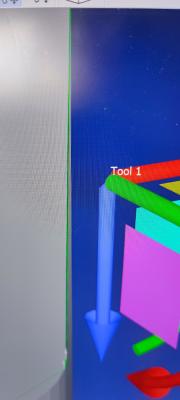

Another example of the position of the tool not following the green line while running the program:

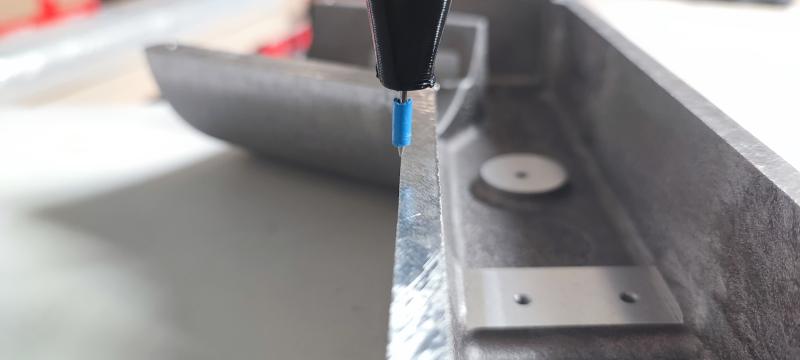

When moving the arm to a random point on the part manually and looking at its position in RoboDk, the location of the tool is correct:

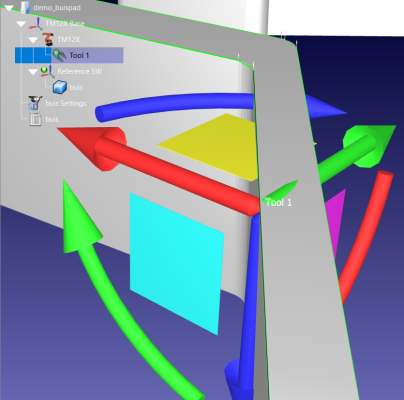

I would think the model and calibration of the reference frame to not be the problem, since the offset is present both in RoboDk and real life, and sampling a random point while checking its position in RoboDk and real life is accurate (enough. I agree that some error can be attributed to the model and calibration of reference frame).

What could be the issue? What is causing this error between the path and the actual tool position?

Another example of the position of the tool not following the green line while running the program:

When moving the arm to a random point on the part manually and looking at its position in RoboDk, the location of the tool is correct:

I would think the model and calibration of the reference frame to not be the problem, since the offset is present both in RoboDk and real life, and sampling a random point while checking its position in RoboDk and real life is accurate (enough. I agree that some error can be attributed to the model and calibration of reference frame).

What could be the issue? What is causing this error between the path and the actual tool position?