01-20-2021, 12:01 PM

Hi,

I am a researcher at the University of La Rioja (Spain).

We have a TM5-700 robot and we are trying to define the TPC in RoboDK by using the 6-point method, connecting to the robot and getting the coordnates. We are following the instructions of the video tutorial "TCP definition - RoboDK - Omron TM Cobot Training - Part 12" at the RoboDK Youtube channel.

According to the video tutorials, the values of the joints should not be used, because of some discrepancy that is introduced by the factory calibration of the TM Robots. Instead, the XYZ and rotation coordinates of the flange should be used with these robots. So, in the video tutorials, the command FLANGE_XYZ is used to get these coordinates and use them as the poses to define the TCP. According to the tutorial, the XYZ and rotation coordinates of the flange in TMFlow and in RoboDK should match by using this command.

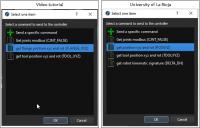

However, we have noticed that the command list is different in our version of RoboDK (v5.2.1) than from the one in the video tutorial (see the attached image). In our case, we do not have the command FLANGE_XYZ. Instead, we are using the command POSXYZ, which we supposed that would do the same, but we cannot obtain the propper coordinates for the TCP definition. As we have seen, it seems that RoboDK gets the coordinates of the flange of the real robot, but it immediately assigns them to the tool (not the flange), thus making the robot in RoboDK to adopt a very different pose than that of the real robot.

Is there something that we are doing wrong? Is there another way to do the TCP definition after the last updates?

Thank you very much!

Rodolfo

I am a researcher at the University of La Rioja (Spain).

We have a TM5-700 robot and we are trying to define the TPC in RoboDK by using the 6-point method, connecting to the robot and getting the coordnates. We are following the instructions of the video tutorial "TCP definition - RoboDK - Omron TM Cobot Training - Part 12" at the RoboDK Youtube channel.

According to the video tutorials, the values of the joints should not be used, because of some discrepancy that is introduced by the factory calibration of the TM Robots. Instead, the XYZ and rotation coordinates of the flange should be used with these robots. So, in the video tutorials, the command FLANGE_XYZ is used to get these coordinates and use them as the poses to define the TCP. According to the tutorial, the XYZ and rotation coordinates of the flange in TMFlow and in RoboDK should match by using this command.

However, we have noticed that the command list is different in our version of RoboDK (v5.2.1) than from the one in the video tutorial (see the attached image). In our case, we do not have the command FLANGE_XYZ. Instead, we are using the command POSXYZ, which we supposed that would do the same, but we cannot obtain the propper coordinates for the TCP definition. As we have seen, it seems that RoboDK gets the coordinates of the flange of the real robot, but it immediately assigns them to the tool (not the flange), thus making the robot in RoboDK to adopt a very different pose than that of the real robot.

Is there something that we are doing wrong? Is there another way to do the TCP definition after the last updates?

Thank you very much!

Rodolfo