Posts: 4,628

Threads: 2

Joined: Apr 2018

Reputation:

215

Do you have the Program Loop option checked?

Can you share the RDK project file?

Posts: 4,628

Threads: 2

Joined: Apr 2018

Reputation:

215

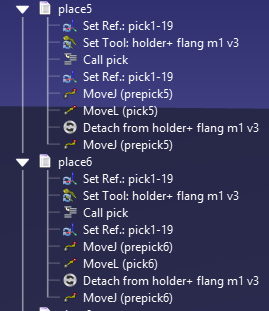

I don't understand what you mean. Both programs are different but they both call the pick program which has additional movements. Therefore, the pick sequence will be the same for both.

Posts: 6

Threads: 2

Joined: Jul 2023

Reputation:

0

07-09-2023, 03:17 PM

(This post was last modified: 07-09-2023, 03:17 PM by kong.)

In programs place 3 4 5 no repeats 2 rounds but place6 repeats 2 rounds

I may not type English fluently. Sorry

Posts: 4,628

Threads: 2

Joined: Apr 2018

Reputation:

215

I don't understand what you mean. When I run the place program they are executed once.

It would be great if you can share a video. You should not have issues uploading small MP4 videos here.

Posts: 4,628

Threads: 2

Joined: Apr 2018

Reputation:

215

It looks like the pick operation is grabbing the conveyor. You can lock the conveyor and any other parts (right click on the object and select Lock), so you can make sure the robot does not take these parts.