12-17-2019, 08:23 PM

(This post was last modified: 12-17-2019, 08:48 PM by cotenicolas.)

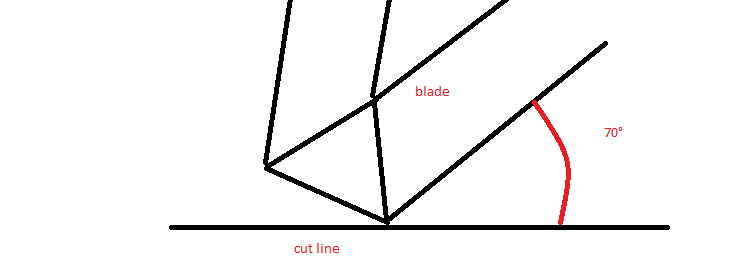

i'm trying to cut a hole into a part using a knife blade. The part is held into the robot arm and the blade fixed in space.

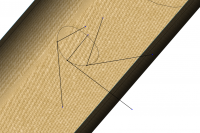

here is the part and cut section that I want to cut using the knife blade

Since this is a knife blade, the knife blade must rotate to be able to stay tangeant to the cut line . The blade must also have an angle of attack (alpha) around 70°

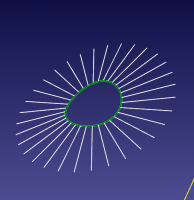

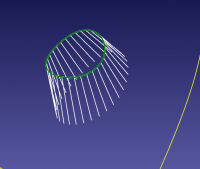

I've imported the curves using solidworks plugin, I've tried two scenarios : Scenario 1 where the normals of the cut line are parallel to the part surface

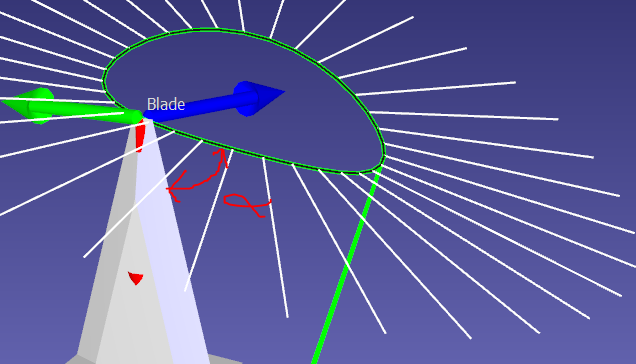

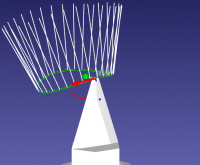

Using this, the knife rotates around the cut line, however the angle of attack of the blade (alpha) doesnt stay consistent throughout.

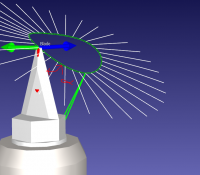

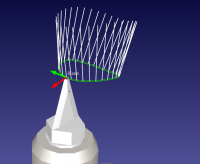

Second senario, I selected the normals perpendicular to the part

The orientation of the blade along the cut line seems to be pretty good, however, it doesnt rotate to follow the path

How do I set the parameters so that the blade stays tangeant to the cut line, and has the right angle compared to the surface of the part?

here is the part and cut section that I want to cut using the knife blade

Since this is a knife blade, the knife blade must rotate to be able to stay tangeant to the cut line . The blade must also have an angle of attack (alpha) around 70°

I've imported the curves using solidworks plugin, I've tried two scenarios : Scenario 1 where the normals of the cut line are parallel to the part surface

Using this, the knife rotates around the cut line, however the angle of attack of the blade (alpha) doesnt stay consistent throughout.

Second senario, I selected the normals perpendicular to the part

The orientation of the blade along the cut line seems to be pretty good, however, it doesnt rotate to follow the path

How do I set the parameters so that the blade stays tangeant to the cut line, and has the right angle compared to the surface of the part?