Sporadic path deviations between Fusion360 and reality

after a long time of experimenting and building, my milling machine with a KR360 (KRC2 edition 05) and a self-made turntable is now ready and works so far well. In most cases, the milling tool follows the specified path without any problems and with sufficient accuracy. Unfortunately, sometimes there are movements that do not exist in the simulation that destroy the workpiece.

But first from the beginning:

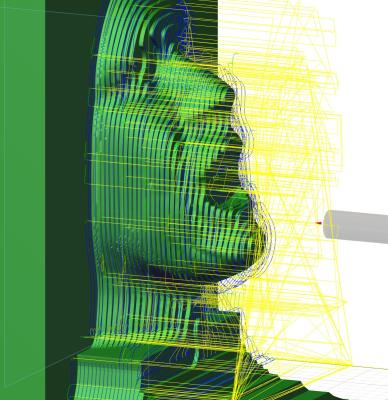

This is how the CAM calculation looks in Fusion360. The tool path is correct and not too much material is removed during the roughing process.

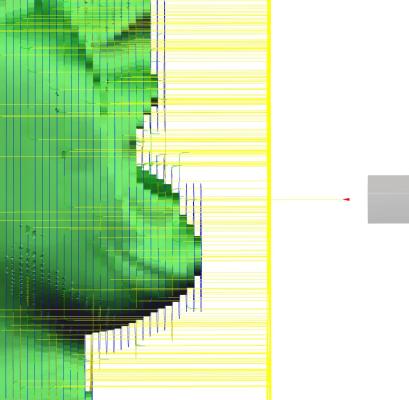

Here again a little more detail. The chin region is cleanly roughed up.

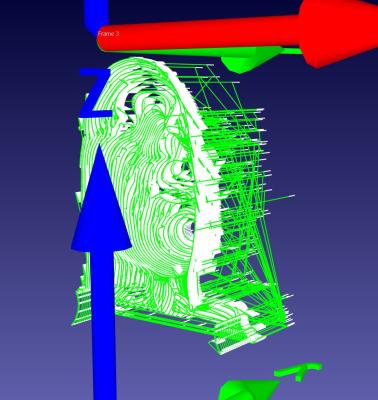

This is how the path looks in RoboDK. Even though it's hard to see, the path looks good so far. I can't see any movements that would explain the faulty milling to me.

To be on the safe side, I also loaded the model of Fusion360's simulation into RoboDK, no path penetrates the model.

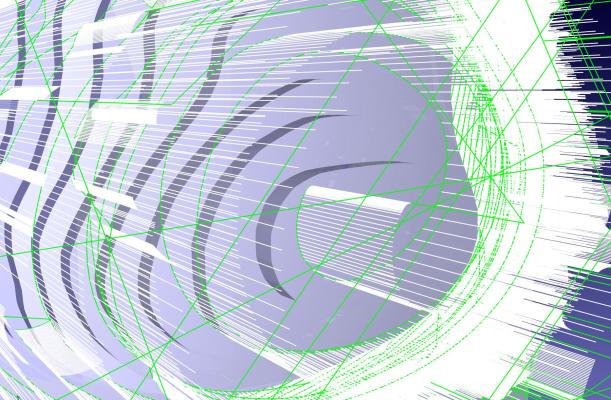

In reality, the result looks like this. At the point marked in red, the milling head moves much too deeply into the material. Such errors happen again and again on the test parts. Fortunately, this error has already occurred in line 5500 and I have observed it with my own eyes. The milling tool repeatedly enters this position cleanly. A sporadic electrical fault can thus be ruled out. It looks like material has been removed from the blue arrow in the wrong place one layer before. First I suspected that the $ADVANCE =3 is too large and therefore the accuracy is too low. Unfortunately, even a $ADVANCE =1 brought no change, the tool moves exactly the same in the red marked zone

Now I don't know how to solve this (hopefully small detail). Otherwise everything runs pretty well!

This is how the code looks:

I would be very happy if someone with more experience with RoboDK could give me some tips.

Chris

after a long time of experimenting and building, my milling machine with a KR360 (KRC2 edition 05) and a self-made turntable is now ready and works so far well. In most cases, the milling tool follows the specified path without any problems and with sufficient accuracy. Unfortunately, sometimes there are movements that do not exist in the simulation that destroy the workpiece.

But first from the beginning:

This is how the CAM calculation looks in Fusion360. The tool path is correct and not too much material is removed during the roughing process.

Here again a little more detail. The chin region is cleanly roughed up.

This is how the path looks in RoboDK. Even though it's hard to see, the path looks good so far. I can't see any movements that would explain the faulty milling to me.

To be on the safe side, I also loaded the model of Fusion360's simulation into RoboDK, no path penetrates the model.

In reality, the result looks like this. At the point marked in red, the milling head moves much too deeply into the material. Such errors happen again and again on the test parts. Fortunately, this error has already occurred in line 5500 and I have observed it with my own eyes. The milling tool repeatedly enters this position cleanly. A sporadic electrical fault can thus be ruled out. It looks like material has been removed from the blue arrow in the wrong place one layer before. First I suspected that the $ADVANCE =3 is too large and therefore the accuracy is too low. Unfortunately, even a $ADVANCE =1 brought no change, the tool moves exactly the same in the red marked zone

Now I don't know how to solve this (hopefully small detail). Otherwise everything runs pretty well!

This is how the code looks:

Code:

&ACCESS RVP

&REL 4

&PARAM TEMPLATE = C:\KRC\Roboter\Template\vorgabe

&PARAM EDITMASK = *

DEF Pusteblume ( )

;FOLD INI

;FOLD BASISTECH INI

GLOBAL INTERRUPT DECL 3 WHEN $STOPMESS==TRUE DO IR_STOPM ( )

INTERRUPT ON 3

BAS (#INITMOV,0 )

;ENDFOLD (BASISTECH INI)

;ENDFOLD (INI)

;FOLD STARTPOSITION - BASE IS 17, TOOL IS 1, SPEED IS 45%, POSITION IS A1 55,A2 -50,A3 50,A4 5,A5 0,A6 -5,E1 0,E2 0,E3 0,E4 0

$BWDSTART = FALSE

PDAT_ACT = {VEL 45,ACC 100,APO_DIST 50}

FDAT_ACT = {TOOL_NO 1,BASE_NO 17,IPO_FRAME #BASE}

BAS (#PTP_PARAMS,80)

PTP {A1 55,A2 -50,A3 50,A4 5,A5 0,A6 -5,E1 0,E2 0,E3 0,E4 0}

;ENDFOLD

;FOLD LIN SPEED IS 0.5 m/sec, INTERPOLATION SETTINGS IN FOLD

$VEL.CP=0.5

$ADVANCE=3

;ENDFOLD

PTP {A1 -23.33140,A2 -49.55890,A3 104.71900,A4 152.47600,A5 58.26180,A6 -74.75400,E1 0.44815,E2 0.00000} C_PTP

LIN {X 34.437,Y 205.000,Z -185.360,A 180.000,B -0.103,C -90.000,E1 0.44815,E2 0.00000} C_DIS

$VEL.CP = 1.00000

LIN {X 34.437,Y 175.000,Z -185.360,A -180.000,B -0.103,C -90.000,E1 0.44815,E2 0.00000} C_DIS

...

...

LIN {X -99.712,Y 305.000,Z -316.287,A -180.000,B -0.103,C -90.000,E1 0.44815,E2 0.00000} C_DIS

ENDChris