11-30-2022, 03:13 AM

Our arm had a pretty significant collision and we ended up replacing the spindle. I have a calibrated cell that I was about to start filtering programs through, but after the collision I wanted to recalibrate it with the new spindle.

1) is this necessary? If not, I'll stop here and start filtering. I don't have a ballbar to test it as is, maybe I could mill a small test part instead to verify it.

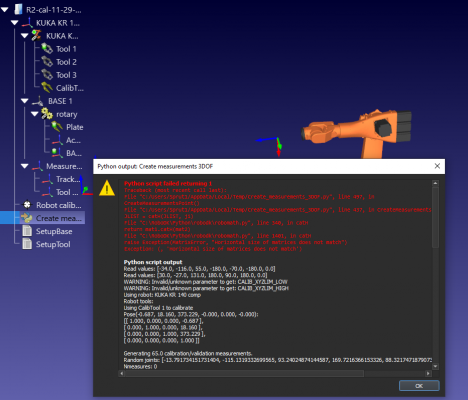

2) I was setting up the cell and got to the point to create the 65 calibration poses, and keep getting a python code failure.

1) is this necessary? If not, I'll stop here and start filtering. I don't have a ballbar to test it as is, maybe I could mill a small test part instead to verify it.

2) I was setting up the cell and got to the point to create the 65 calibration poses, and keep getting a python code failure.