Efficiency is often the word on the tip of every manufacturer’s tongue when they are thinking about improving their processes.

And rightfully so! Improving your efficiency can lead to spending less to produce the same products and becoming more competitive in the global marketplace.

There are various ways to improve manufacturing efficiency. But not all of them will work for every manufacturer. The best way to improve your manufacturing efficiency is to take a holistic approach and look at your entire process from start to finish.

Here are 10 perfect ways to improve manufacturing efficiency:

1. What is Manufacturing Efficiency? Define Your Terms

Manufacturing efficiency is a term used to describe the overall effectiveness of a manufacturing process. It is often measured by the amount of product produced relative to the resources used to produce it. In other words, manufacturing efficiency is a ratio of outputs to inputs.

This is the general definition… but it’s always a good idea to start by defining your terms.

Like all companies, you will have your own definition of efficiency based on your specific products and processes. You need to define what efficiency means for your company before you can improve it.

2. Use Manufacturing Efficiency Metrics to Track Progress

If you can’t measure it, you can’t improve it.

There are several metrics that you could use to track your progress toward improving manufacturing efficiency. Which you choose will depend on your specific needs.

Some common efficiency-related metrics include:

- Overall Equipment Efficiency (OEE)

- Total Effective Equipment Performance (TEEP)

- Overall Operations Effectiveness (OOE)

- Throughput

- On Standard Operating Efficiency

- Asset Utilization

Each metric measures different aspects of the manufacturing process. By tracking the right metrics, you can see the impact of your changes.

3. Streamline Communication Across All Departments

Effective communication is essential for any business, but it is especially important in manufacturing. To improve efficiency, it helps to streamline communication across all departments.

A streamlined communication process can help you solve potential issues before they become problems, such as those associated with inefficient project management, information overload, and unrealistic targets.

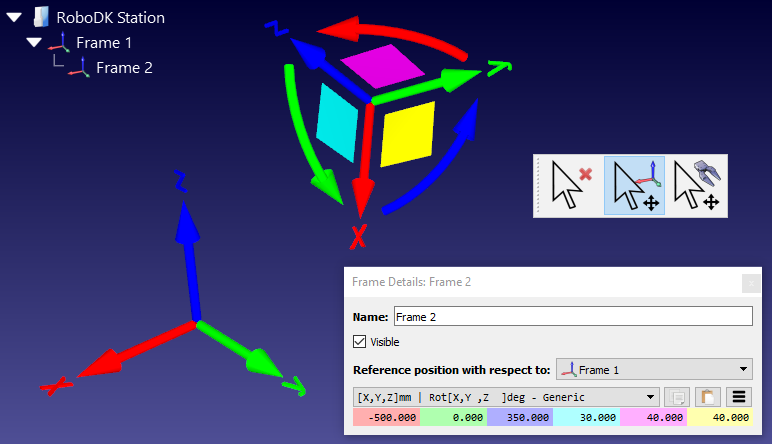

RoboDK for Web is a valuable tool for improving communication around your robotic deployments. It allows you to easily share your robotic projects with others, no matter where those people are in the world or what device they are using.

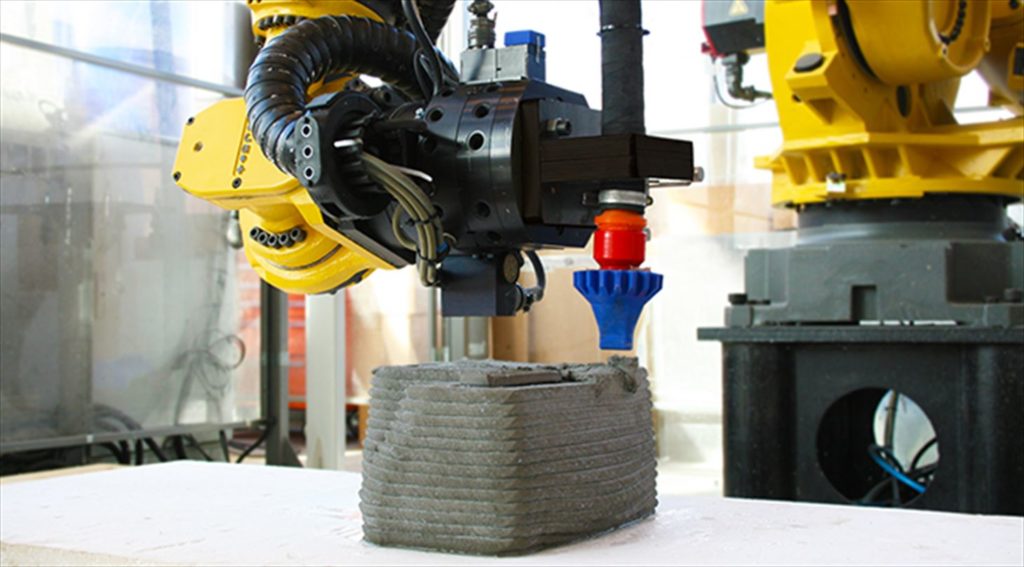

4. Implement a Robotic Solution for Quality and Consistency

One of the most reliable ways to improve efficiency in manufacturing processes is to add robotic automation. Robots can work faster and more consistently than humans, leading to increased quality and reduced machine downtime.

You can apply robots to many tasks in a manufacturing business, including:

- Assembly

- Painting

- Welding

- Inspection

- Packaging

- Palletizing

- and many more.

5. Use Conveyor Systems to Move Parts and Products

Time lost to transportation is one of the major wastes in manufacturing. Conveyors are a very well-established tool for moving parts and products through a manufacturing facility quickly.

When you are using conveyors, you also need to ensure you are using them efficiently. This includes setting the right flow rate and optimizing their operation for the loads each conveyor will be carrying.

RoboDK makes it easy to add conveyor systems to your robotic cell. With RoboDK’s built-in conveyor belt objects, you can easily simulate a conveyor belt in your environment. This helps you optimize the position and orientation of your robots to improve efficiency.

6. Use Software to Improve Manufacturing Efficiency

There are various software solutions that can help you improve manufacturing efficiency. Which type is right for you will depend on which aspects of your operations you want to make more efficient.

Some popular manufacturing software types include:

- Manufacturing Execution Systems (MES)

- Factory simulators, such as logistics, fluid, or material handling simulation

- Enterprise Resource Planning (ERP) systems

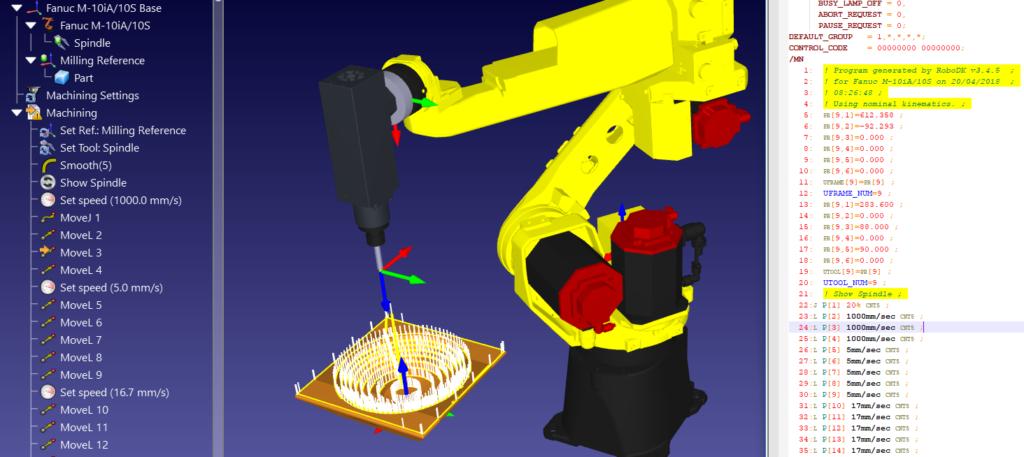

- Robot simulation programs like RoboDK

7. Reduce Downtime in as Many Ways as You Can Find

Another way to improve your manufacturing efficiency is to reduce downtime. Downtime is when a part of your process cannot operate effectively because of factors like maintenance, employee breaks, or underutilization.

There are many ways you can minimize downtime in your business including implementing preventative maintenance, training employees in new skills, and using robotic automation.

8. Optimize Your Plant Layout Design

The layout of your facility can have a noticeable impact on manufacturing efficiency. An inefficient plant layout can lead to longer travel distances, increased downtime, and a higher level of stress for employees.

Tips for optimizing your plant layout design include breaking your task into steps, minimizing movement waste, and designing your automation solutions around your space restrictions.

9. Train Your Employees On New Technologies

Your employees are a critical part of your manufacturing process. By training them to use the latest manufacturing techniques and technologies, you help them improve their own efficiency.

When your employees are familiar with the capabilities of technologies like robotics, they will work more effectively with these technologies. This helps improve your overall efficiency and can lead to increased productivity.

RoboDK provides a number of free resources to help train your employees to use robots.

10. Implement These Strategies with RoboDK

Robot simulation can be a valuable tool for applying strategies like these to your manufacturing operations.

RoboDK can help you improve efficiency in various ways, including helping you to:

- Optimize the design of your robot deployment in simulation

- Train your employees on robotics technologies

- Simulate and optimize the layout of your robotic processes

- Generate CNC programs for robot machining and machine tending

Even without simulation, robots are a great way to improve efficiency. But, by implementing your efficiency improvement strategies with RoboDK, you can get the most out of a robotic investment.

Which parts of your manufacturing process reduce efficiency more than anything else? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum. Also, check out our extensive video collection and subscribe to the RoboDK YouTube Channel.