Is your factory as efficient as you’d like it to be? You might wonder if factory simulation might be the solution to all your problems.

But what is factory simulation?

What properties should you look for in simulation software?

You might think that you don’t have the time, expertise, or resources to use factory simulation in your facility. And maybe you don’t…

For many manufacturers, full simulation of their factory is overkill. It is a complex process and takes a lot of time.

If your factory is already up and running, it might be better to simulate only particular parts of it. Those parts that you want to improve and make more efficient.

Here’s a brief introduction to using factory simulation software if you’re a busy manufacturer.

What is Factory Simulation?

Factory simulation involves using computer software to model, analyze, and improve the processes within a production facility. On a large scale, it involves simulating an entire factory and all the processes within it. On a smaller scale, it involves using specialist simulation software for particular processes.

When you think of factory simulation, you might imagine the software packages that are used to design large factories from scratch. This is certainly a common application. However, you don’t need to be designing a whole new factory from scratch to benefit from some aspects of factory simulation.

For example, perhaps you are designing a robotic application to automate a process. In this case, a good robot simulation software would be a very useful type of factory simulation for you.

Do You Need Factory Simulation Software as a Manufacturer?

You might be uncertain whether you actually need factory simulation.

It doesn’t matter if you are using a full factory simulation package or just a specialist simulator (like a robot simulator). Whatever your application, there are great reasons for simulating your process.

Some good reasons for choosing factory simulation are that it:

- Increases your understanding of the production operation.

- Promotes standardization across the factory. Using the same software means more consistency.

- Allows you to model and analyze your factory processes, leading to continuous improvement.

- Let’s you perform a “what if” analysis, helping to avoid disaster in the long run.

Siemens’ researchers note that simulation isn’t a “panacea”. But, while it doesn’t solve all problems that can arise in a factory, it can be an extremely useful tool for any manufacturer.

5 Factory Simulation Software Features You Can Benefit From

What features should you be looking for in any factory simulation software? The specific features that will serve your needs will depend on which processes your factory includes.

Here are 5 features that you might benefit from:

1. Robot Simulation

If you are automating any aspect of your process with a robot, you will want to use robot simulation software.

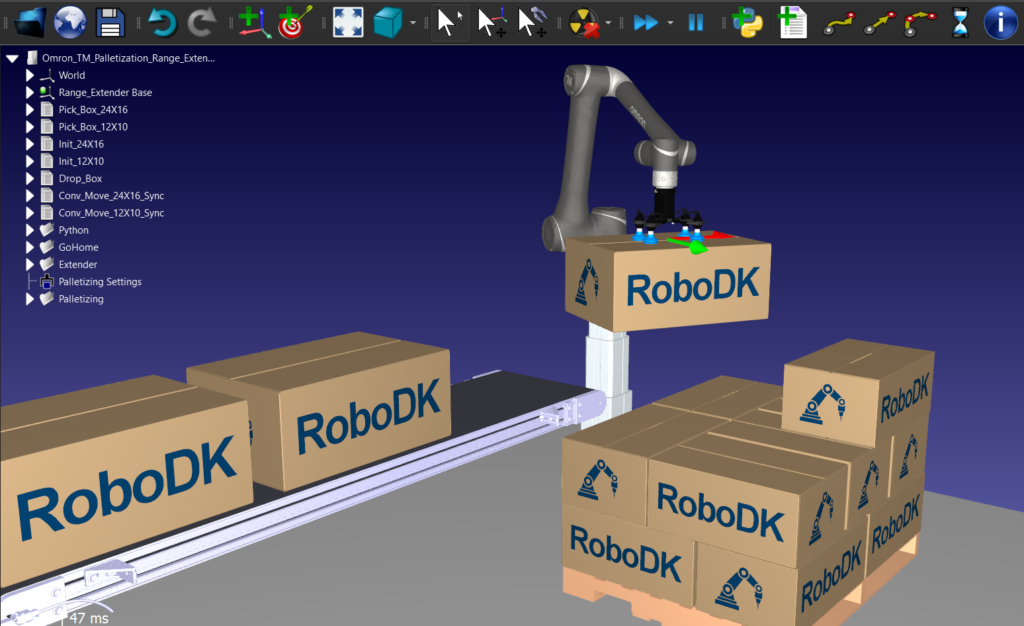

RoboDK is a highly-popular robot simulation software. It supports hundreds of robot models from dozens of brands. Its offline programming functionality also means that you can program your physical robot directly from the simulation, saving huge amounts of time.

2. Logistics Simulation

Logistics is an increasingly important part of any modern manufacturing business. Simulating logistics simulation allows you to streamline aspects of your logistics processes.

By making your logistics processes more efficient, simulation helps you to get more products to your customers quicker and with less waste.

3. Process Simulation

You can simulate almost any process in your manufacturing factory. By modeling these processes using general simulation, you can identify ways to improve the ones that you might have missed otherwise.

Process simulators usually represent the operations in your factory with standardized components such as queues, delays, transactions, and resource utilization.

4. Fluid Simulation

The fluid simulation will likely only be applicable to you if your manufacturing factory handles fluids. Such simulators model how fluids move through parts of a factory.

Fluid simulators are often standalone software packages, though they can also be incorporated into more general-purpose factory simulators.

5. Material Handling Simulation

When simulation material handling, it involves the transportation and storage of raw materials. Material handling simulation helps you to optimize these processes to avoid the wasteful buildup of inventory.

For some material handling simulations, a robot simulator can be helpful if you are using robots to process your inventory.

6 Functional Requirements for Good Factory Simulation Software

What are the markers of good factory simulation software?

Here are 6 functionalities that are useful in factory simulation:

- Create and lay out 3D geometry — It should be easy to build your simulation in 3D and change the layout. For example, in RoboDK you can drag items with the mouse or enter their precise location.

- Define features and constraints — Features should be quick and easy to define, such as adding a target location for your robot to move to.

- Add non-geometrical information — Simulation is more than just 3D CAD design. You should be able to add extra information, such as the speed and acceleration of a robot.

- Provide libraries of components — The software should support a large catalog of components, as is the case with the RoboDK Library.

- Import and export common file formats — Your simulator shouldn’t restrict the file formats you can use. For example, RoboDK supports most standard file formats.

- Analyze and test the layout — The simulator should make it easy to test different configurations of your components so you can optimize your layouts.

There are, of course, many more functionalities that might be necessary for your specific situation. It’s a good idea to write down your required functionalities before you start your search for a simulator.

How to Find the Right Software for Your Factory Simulation

The right factory simulation software for you will depend hugely on which aspects of your factory you want to improve.

If you are looking to add robotics and automation to your factory, a good robot simulator would make the most sense. While you won’t simulate absolutely every aspect of your factory with such a simulator, it has a wide enough applicability and flexibility to be useful without being overwhelming.

What aspect of your factory do you most want to simulate? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.. Also, check out our extensive video collection and subscribe to the RoboDK YouTube Channel