05-22-2021, 05:58 PM

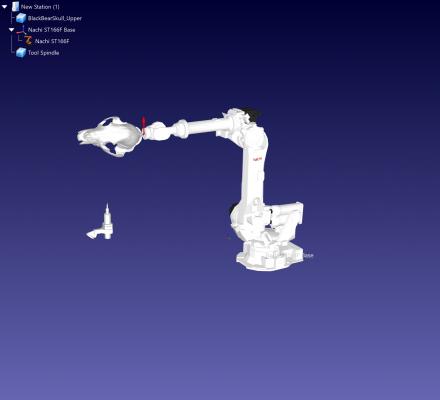

I am wanting to use my robot to carve soft material such as a urethane foam block. Since I do not have a turn table it seems I could accomplish the task if the robot holds the block and moves it against a stationary tool. See the attached photo.

The problem I am having is creating the tool path in master cam. Master cam does not have a machine definition for what is called a head/head machine. Am also having trouble with master cam as I can't get it to cut inside the eye sockets.

Part of the problem is I don't know how RoboDK chooses to translate tool paths. Could I use a machine that has a the 4 & 5 axis on the table to create the tool path. Could RoboDK use that and translate it to the stationary tool setup?

The problem I am having is creating the tool path in master cam. Master cam does not have a machine definition for what is called a head/head machine. Am also having trouble with master cam as I can't get it to cut inside the eye sockets.

Part of the problem is I don't know how RoboDK chooses to translate tool paths. Could I use a machine that has a the 4 & 5 axis on the table to create the tool path. Could RoboDK use that and translate it to the stationary tool setup?