Adding robots to your business? It used to mean to mean investing big in software and changing everything. But, it doesn’t have to be like this!

Some years ago, I started a new position in a robotics research lab. The robot that they were using — a hulking, black hydraulic monster — was rigged up with a proprietary hardware interface. The whole system was locked into this hardware… and the programming language that it used.

I was sent on a training course to use the hardware. But, there was a problem. I hated the programming language. Its clunky graphical interface didn’t suit my preference for text-based programming. But, I had no option. I had to use it or I couldn’t use the robot.

Slowly, I became adept at using the system. However, realistically, it was over a year until I was an expert in programming the robot. I would have been up and running much quicker if I’d been able to program in one of my favorite programming languages from the start.

If I had been working in a manufacturing environment instead of in a research lab, this could have severely restricted the robot’s productivity!

Unfortunately, this can be a common situation with robots.

Why Robot Software Is Often Inflexible

A traditional problem with robots is that every manufacturer uses their own software.

Many industrial robot manufacturers create their own programming languages, design packages, and software tools. Sure, this has an advantage. It allows users access to all of the functionality of their robots. But, it comes at a terrible cost.

When you add a new robot to your business, you often have to change how you do things to accommodate the robot.

At RoboDK, we think that this is unacceptable. It should be the other way round.

It doesn’t have to be like this…

The Power of Plugins and Interoperability

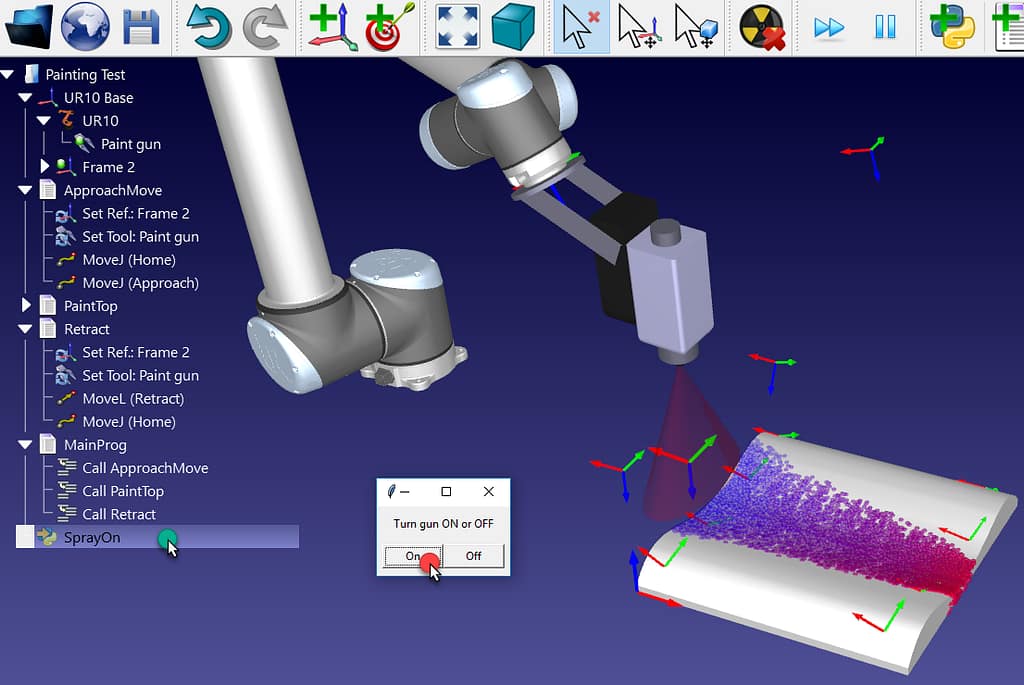

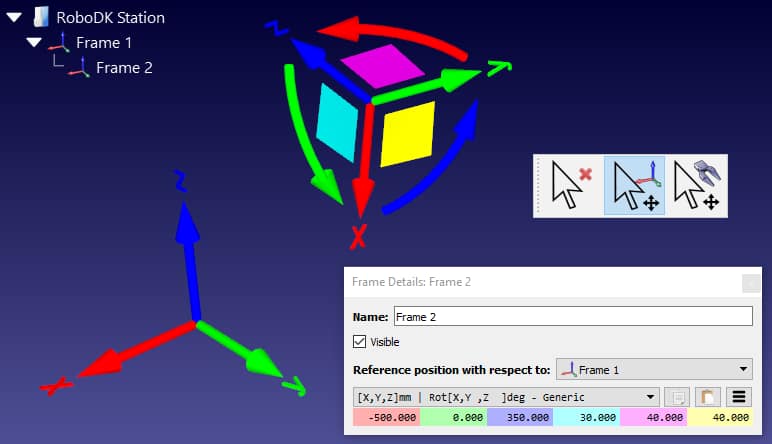

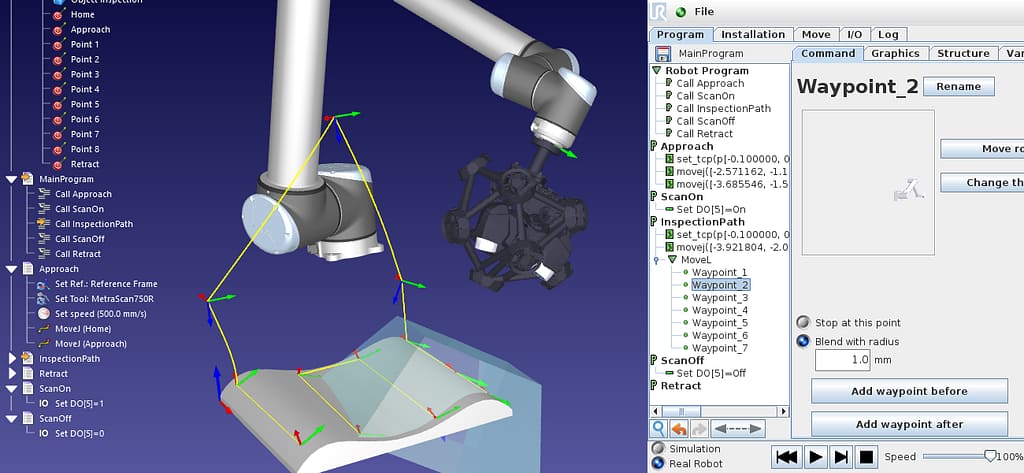

On the surface, RoboDK is just an offline programming software for industrial robots. But, it’s really much, much more than that.

RoboDK can be a bridge between your favorite CAD/CAM software and your preferred robot.

There’s no need to change which design packages you use.

There’s no need to tie yourself in knots trying to get the robot software to play nice with your favorite CAM package.

There’s no need to change everything to accommodate the robot.

You simply slot RoboDK into your workflow between your existing CAD/CAM package and the physical robot. You can then turn your designs into robot programs with no fuss.

That’s the power of interoperability.

The Age of Interoperability

“Interoperability” means the ability of different computer softwares to exchange and make use of information.

We are currently entering The Age of Interoperability.

Think of all the software automation services that are available these days. The type of services which send a Twitter post whenever you post an image on Facebook, or which turn off your home heating automatically whenever your calendar says you’re on holiday. Interoperability allows us to spend more time doing the important tasks, without having to mess around copying data from one place to another.

Entirely closed systems are becoming a thing of the past.

We’re seeing interoperability in a whole range of industries. According to one research study, for example, within the construction industry “multidiscipinary software interoperability is becoming a widely adopted business culture.”

That’s why it’s surprising that interoperability is so limited in industrial robotics. Sure, software developers can create plugins for specific robot manufacturers. But, there are very few independent solutions which allow you to connect your favorite CAD/CAM package with your favorite robot.

RoboDK is that very solution.

With our new set of software plugins, it’s now easier than ever to use your robot on your own terms.

The 6 New RoboDK-Supported Plugins

Plugins are one of the most intuitive ways to connect two softwares together.

In the latest version of RoboDK, we have added some new plugins which increase its interoperability with some very popular CAD/CAM programs.

The release includes the following three plugins:

- SolidWorks — This plugin provides a seamless link between the most popular CAD package and RoboDK. Do you use SolidWorks? Read this article to learn what it does.

- Mastercam — The most popular high-end CAM package is now also supported out the box. Read this article to learn what the new plugin does.

- Rhino — This plugin for one of the most popular freeform surface modeling CAD packages allows you to achieve astonishing new applications with RoboDK. Read this article to learn more.

The release also includes support for the following three plugins (available from the suppliers):

How Plugins Can Improve Your Workflow

We often talk about “workflow” in business, but many of us have little “flow” in our work. We jump around from task to task doing a little bit of this and a little bit of that. Even in manufacturing businesses, where the concept of “process flow” is strongly established, it’s common to see processes which are not well optimized.

The problem with this is that it can severely restrict productivity. According to psychologists, task switching (i.e. jumping between tasks) can cut a person’s productivity by 40%.

Whenever we open a new software program, it takes time to re-accustom ourselves with it. This can be a real problem when we’re jumping between software packages all the time.

We might tweak our design in a CAD package, then open up a separate CAM package to update the machining path. Then, if we were using a separate robotics software we would have to export the models and paths, open up the robot software and program with that. All this jumping around takes a lot of time and brainpower.

Our new plugins mean that you can pass information from CAD/CAM packages at the touch of a button. Also, they have in-built themes for SolidWorks, Mastercam and Rhino. This makes it much easier to jump between the programs because the mouse controls and color themes match.

Welcome to The Age of Interoperability!

What interoperability issues have you had with robot software in the past? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram or in the RoboDK Forum.