In an era where advanced technologies are now becoming the norm in manufacturing, automation and robotics could now be a replacement for human welders.

So what is the future of welding jobs?

Will skilled welding become a job of the past?

Will welding join the list of jobs that were “lost” to technology, like switchboard operators, assembly line workers, and human computers?

Welding is a core task in many manufacturing processes. We know that the task of welding is unlikely to go away anytime soon (unless someone comes up with a vastly superior new way of joining metals).

But the job of welding is perfect for robotic automation. Robotic welding is more consistent, safer, and more reliable than manual welding. It may soon be as common as CNC machining, with robots becoming the obvious choice for most welding tasks.

The question becomes…

What will the job of the welding professionals become?

The Current State of Welding

The welding industry is currently at a crossroads.

According to research by the American Welding Society the majority of welding professionals are aged over 45. There is a growing concern for about the shortage of skilled workers.

This shortage has a significant impact on manufacturing companies. For example, it leads to project delays and increased labor costs as businesses compete for a few skilled workers.

The welding community knows that robotics is one way to solve this problem. When polled, many of the research participants saw robotic welding as part of the solution, not a threat.

Of course, robotics isn’t the only solution… but it is one of the fastest to implement.

Other ways that the welding industry is working to tackle the skills shortage is by investing in comprehensive training programs, apprenticeships, and retraining initiatives. In the long term, this will help return skilled welders to the workforce, but it will take time.

The Rise of Robotic Welding

Robotic welding has been around for years — the first welding robot was, in fact, the first ever industrial robot! The Unimate, created in 1962, performed welding in the automotive industry.

Despite this early start, it has taken time for robotic welding to really stick in some industries. For many companies, adding robots is still a daunting prospect. Welding professionals may not have enough experience with robots to be comfortable working alongside them.

However, there are now so many benefits to robotic welding that it’s hard to ignore.

A few of these benefits include:

- More efficient gas management.

- Tracking and data analysis.

- Optimized use of wire and other consumables.

- More consistent weld quality.

- Continuous operation without breaks.

Robotic welding is well and truly here to stay. But that doesn’t mean that human welders are out of a job.

The Human Element in Welding

Despite the rise of robotic welding, the human touch remains integral to the welding process.

Humans outperform robots in complex decision-making, problem solving, and customization.

A robot can perform exactly the same weld the same way every time… but a human can adapt their welding to even the most intricate and complex changes.

We might think that the job of welding has remained fairly stable for the last 50 or more years. However, during this time, a plethora of new technologies has [arrived into the job][NEWTECH] including laser welding, electron beams, and friction stir welding.

With each new technology, welders have been required to learn and adapt to incorporate the new technology into their jobs.

Robotic welding is just the latest of these technologies. The human touch will remain vital because — like all technologies — robots can’t make decisions, adapt to unexpected changes, or solve unknown problems.

In the future, robots might perform the routine welding…

But skilled welders will still do the thinking.

As one industry professional said “My job is a constant evolution. As a welder, I believe that I need to learn something new every day. I’m really impressed with how simple and easy it was to get the robot up and running.”

The Future of Welding

Nobody can say exactly what will happen in the future.

However, the future of welding is likely to involve close collaboration between human welders and robots. With robots handling the repetitive welding tasks, skilled human welders will have more time and energy to focus on more complex, unique, lower-volume tasks.

One thing is certain. The skill of robot programming will be a significant benefit to welding professionals.

By learning to operate and program robots, welders can future-proof their jobs and gain a professional advantage in their careers.

Having more robotic welding experts in the job market could also create a virtuous loop that drives further robot adoption. As more welders are aware of the benefits of robotic technology, they will propose robots as a solution to their teams. This, in turn, will drive the need for even more robot-savvy welding professionals.

How You Can Take Advantage of Robot Welding

What is the first step that you can take to gain an advantage in this world of robot welding?

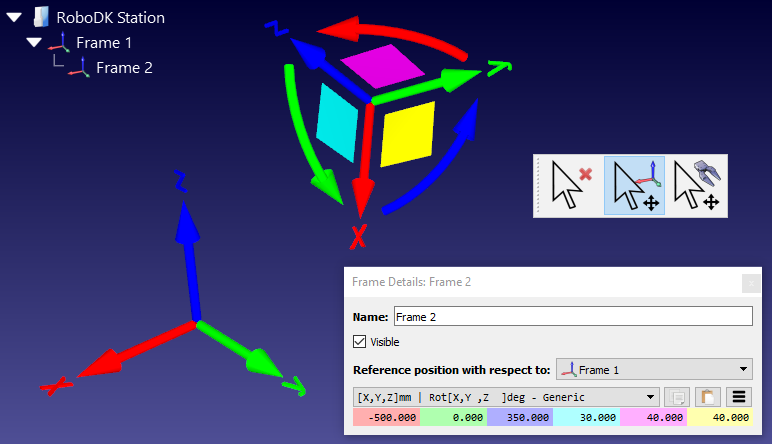

One way you can significantly smooth the barriers to entry into robotic welding is finding the right robot programming platform. A tool like RoboDK can help you to quickly get to grips with robotic technology, even if you don’t yet have access to a physical welding robot.

The Welding Add-in for RoboDK also makes it even easier to program welding tasks. With a range of advanced features to aid the welding process, the barriers to entry are lower than ever before!

What concerns or hopes do you have for the future of robotic welding? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.. Also, check out our extensive video collection and subscribe to the RoboDK YouTube Channel