A pick and place task should be the easiest robot application to program…

They should be at least, but often they are not so simple.

How can you program a pick and place task quickly, easily, and effectively?

Here’s a guide to making programming easy.

It’s clear that some robot programs are harder to create than others. If you’re using complex sensor systems with advanced artificial intelligence algorithms, the programming complexity will also be high.

Some forms of pick and place can be complex — e.g. bin picking, which requires advanced vision algorithms. However, pick and place is usually an extremely simple task. It only involves picking up an item from one location in the robot’s workspace and moving it to another location.

Programming a pick and place task should also be an easy task…

Shouldn’t Programming Pick and Place Tasks Be Easy?

On most robots, pick and place is one of the most straightforward robot programming tasks that you can encounter.

But, that doesn’t mean that it’s always easy.

Sometimes programming is far more complex than it needs to be. You have to fiddle with the robot’s teach pendant, endlessly jogging the robot’s position forward and back. If you want to update a position in the program, it’s awkward and requires you to update far more of your program than you had anticipated. You find yourself constantly having to look up the programming manual to remind yourself of the exact syntax of instructions, using the manufacturer’s programming language.

The problem is that we often think we are limited to only using the programming system that comes from the robot’s manufacturer.

We assume that we have to use the robot’s teach pendant, we have to program using the manufacturer’s programming language, and if we don’t like them there is nothing that we can do.

As a result, people often get stuck using programming methods that require too many lines of code, too many programming steps, and much more time than is really necessary.

Programming a pick and place task should only take a couple of minutes.

5 Different Ways to Program a Pick and Place Task

There are multiple ways you could choose to program a robot for pick and place. Some are easier than others.

Here are 5 of the most common programming methods:

1. From the Robot’s Teach Pendant

The default programming option for most robots is to use the default teach pendant. Although teach pendants can be handy, they usually make programming harder than it needs to be. According to one research survey, users found teach pendant programming to be a “tedious and time-consuming task.” This complexity just doesn’t make sense for a simple task like pick and place.

2. With Hand Guiding

An increasingly popular option for collaborative robots; this programming method involves moving the robot around by hand. It is certainly an easy-to-use option but it suffers from a lack of precision compared to other programming methods. As a result, it’s only really suitable for imprecise pick and place tasks.

3. With the Default Programming Language

The next step from using the teach pendant is to use the robot manufacturer’s default programming language to program the robot offline. If you’re an experienced programmer, this can be pretty quick for a pick and place task as some parts of the program will be easy to copy and paste. However, every robot programming language is different and the task is often clunkier than it needs to be.

4. With Dedicated Offline Programming

Using a good offline programming software can make pick and place programming extremely easy. It can usually be achieved in a matter of minutes and is compatible with any robot. The only potential downside is that it requires you to program the robot from another computer. However, as offline programming is now available for mobile devices, even this is less of a challenge.

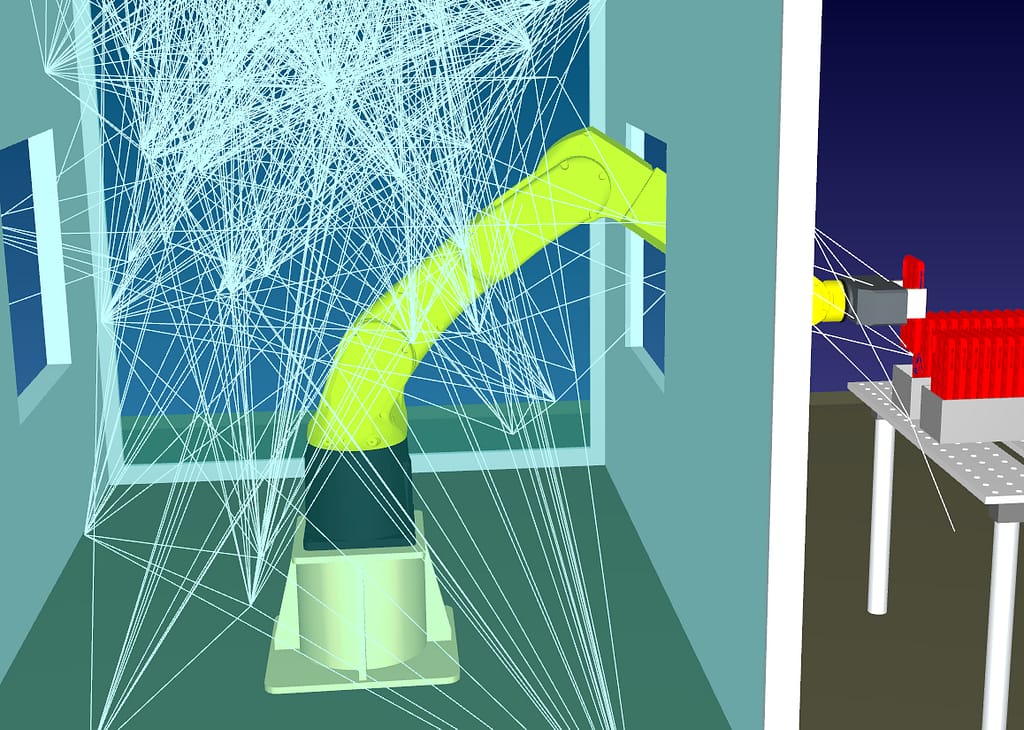

5. With Virtual Reality

Okay, perhaps VR is not a “common” programming method yet, but it seems likely that it will grow in popularity over the coming years. Even now, it’s possible to program a robot with VR.

What’s the Easiest Method to Program Pick and Place?

Unless you are using advanced functionality, such as bin picking, you don’t need to get complicated to program a pick and place task.

If performance isn’t important and your robot supports hand-guiding (though most robots don’t support this), then you could use that option for a quick way to program the task.

However, the easiest option in most cases is certainly with a dedicated offline programming software.

Sure, we might be biased by saying that. But, it’s undeniable that the number of steps that are required to program a pick and place task in RoboDK is much fewer than in many other methods. You can program the task in only a matter of minutes.

3 Simple Steps to Program Your Pick and Place Task

If you are using offline programming, the steps for programming pick and place are very simple.

They are:

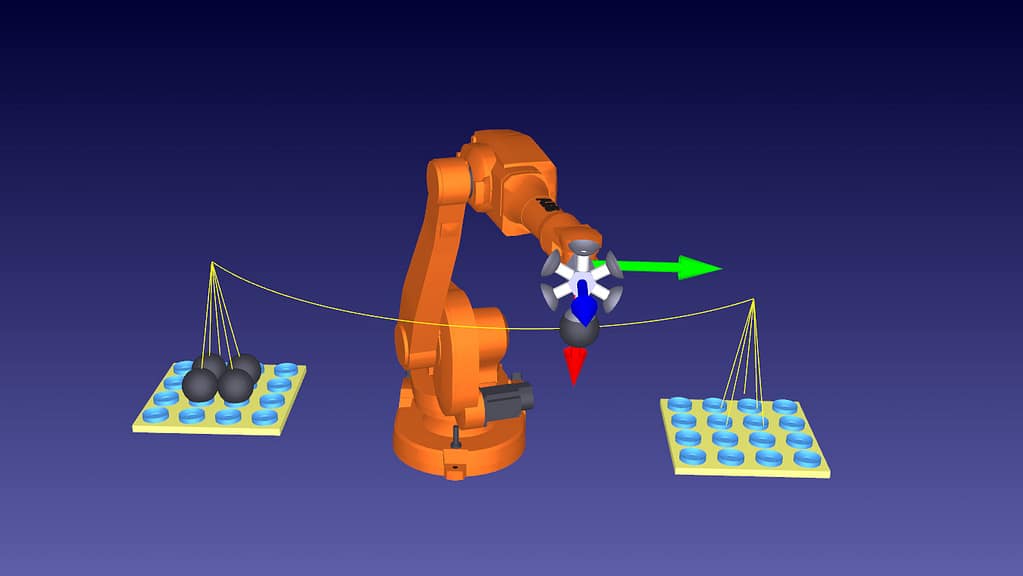

- Set up your robot workstation in offline programming — Add the necessary virtual items and robot to the simulation. The setup doesn’t have to be a full representation of the real environment (in fact, this is usually a waste of time). Just include enough items to complete the task.

- Create targets for the key positions in the task — Then, create the reference frames that are important in the task. The 4 required targets are: the pick location, the place location, and the two associated approach locations.

- Program the robot movements — Finally, create the robot program by cycling through these 4 locations. This should only take a minute or two for simple pick and place tasks.

That is really all it takes to program a pick and place task in offline programming!

A Quicker Way to Learn Pick and Place Programming

Want to see how easy it is to program a pick and place task?

Check out our webinar on pick and place programming.

What pick and place task are you considering? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.