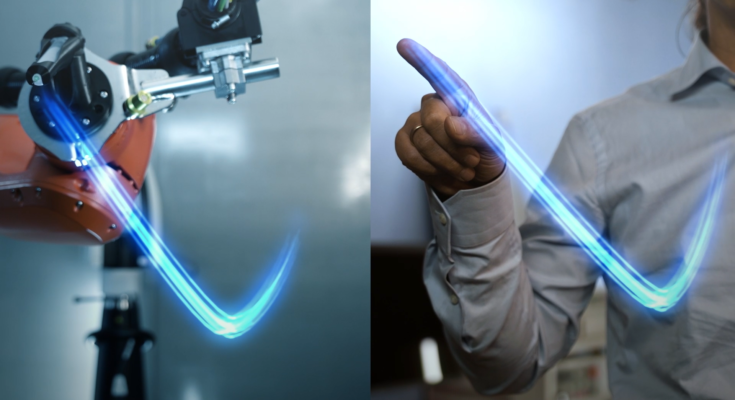

They both provide a more intuitive way to program your robot than conventional programming. But, what’s the difference between TwinTrack and hand guiding?

We just released TwinTrack, our new programming tool for industrial robots. It allows you to program your robot simply by tracing your desired path with the handheld probe of a laser tracker, no conventional programming required.

You might be looking at TwinTrack and wondering “Isn’t it just going to give me the same benefits as hand guiding?”

While there are some similarities between TwinTrack and Hand Guiding, they are very different in what they allow you to achieve.

Here’s a breakdown of the two programming methods.

What is TwinTrack?

TwinTrack provides robot users with a new approach to offline programming. Unlike conventional robot programming – which requires training and often programming skills – TwinTrack can be used by anybody.

If your chosen task is currently performed by a technician, that person can now teach the task directly to the robot without having to rely on programmers who don’t know the task as well as they do.

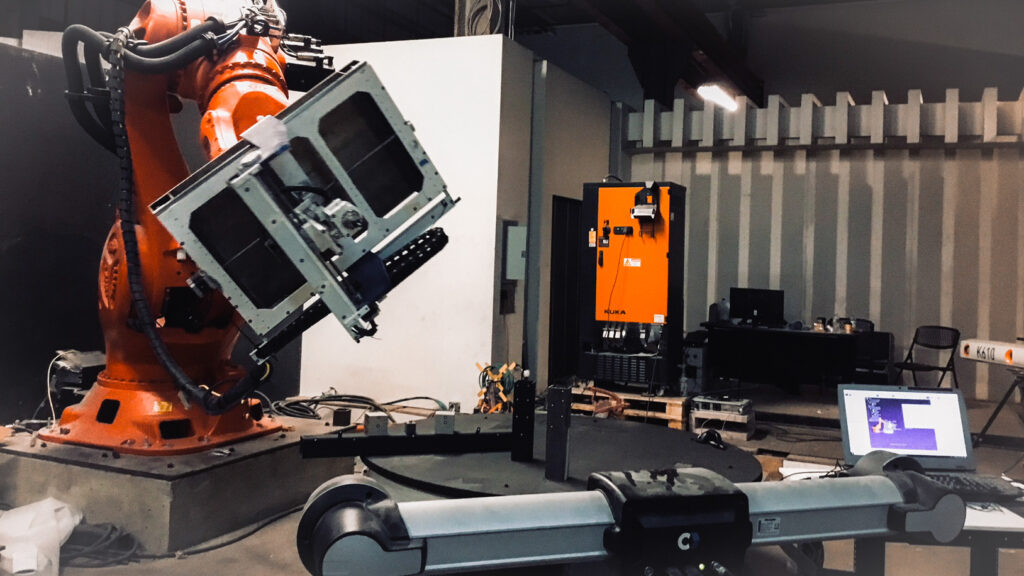

TwinTrack employs an off-the-shelf laser tracker for precise position detection and is compatible with laser scanners from various brands.

What is Hand Guiding?

Hand guiding is a mode of online programming that is usually associated with collaborative robots. It allows the user to program the robot by physically dragging it between the desired locations in the workspace.

As it is an online programming method, it requires access to the physical robot during programming. Also, it requires you to touch the robot when it is operational so the robot must operate in a safe mode at a reduced velocity.

3 Similarities Between TwinTrack and Hand Guiding

At a basic level, there are some similarities between the two programming methods. Here are the 3 most relevant similarities:

1. Don’t Require Conventional Programming

Both TwinTrack and hand guiding provide an easy-to-use way to program a robot without conventional robot programming.

By conventional programming, we mean:

- Using the manufacturer’s proprietary programming language to create programs on the robot’s teach pendant or offline.

- Jogging the robot into position using the robot’s teach pendant.

Both of these options require training and/or significant experience with industrial robotics. As a result, they are not easily accessible to new robot users.

2. Intuitive Target Teaching

Programming a robot involves teaching the targets that you want it to move to. In conventional robot programming, this requires that you have an in-depth knowledge of the coordinate system of the robot. At the very least, you should understand Euler angles and be able to perform geometrical calculations using them.

Both TwinTrack and hand guiding allow you to dispense with these completely. You just indicate where you want the robot to move (using either the handheld probe or the by moving robot itself) and the system learns the target.

3. Both Point and Path Teaching

Most robot movements can be reduced to targets or paths. If you want the robot to move to a particular point, you teach a target. If you want the robot to trace a specific line or curve, you teach it the path.

Both TwinTrack and hand guiding allow you to teach points and paths (though some forms of hand guiding might not support paths).

5 Differences Between TwinTrack and Hand Guiding

While the two programming methods are similar in some ways, there are more differences between them than there are similarities.

Here are 5 important differences between TwinTrack and hand guiding:

1. Speed

One problem with hand guiding is that you need to physically drag the robot around its workspace to teach points and paths. This can take a long time and can be quite tiresome if you have to program a large task.

With TwinTrack, you can program points as quickly as it takes to move your hand to the target locations.

2. Precision

Hand guiding is often criticized for being a low precision method of programming a robot. This is a fair criticism. It’s very difficult to position the robot precisely when you are dragging it around.

As it uses a laser tracker, TwinTrack can detect the target position down to a precision of 0.150mm, the width of a human hair.

3. Robot Compatibility

A major issue with hand guiding is that it is restricted to only a few robot manufacturers. If your manufacturer provides a hand guiding option, you can use it. If not, there is little that you can do.

TwinTrack is compatible out-of-the-box with over 500 robots from 50 robot manufacturers and this number is rising all the time.

4. Offline Programming

A fundamental difference between the two programming methods is that TwinTrack is designed as an offline programming tool and hand guiding is only a form of online programming.

The problem with online programming is that it requires you to have the robot physically present. This means taking it out of production for longer whenever you want to make changes to the robot’s program.

Having said that, it is also possible to use TwinTrack for online programming.

5. Calibration

One added bonus of TwinTrack is that it also allows you to calibrate your robot using only the hardware that it runs on.

Calibration ensures that your robot’s digital twin in the offline programming software is truly an accurate representation of the real robot. Accuracy is a common concern for first-time users of offline programming.

Which is Better? TwinTrack or Hand Guiding?

So, you’ve looked at the similarities and the differences between the two technology and you’re wondering which is the best option for you.

As with so many decisions in life and business, the answer is “It depends.”

If your robot comes with hand guiding and you are not concerned about the speed of programming, precision, offline programming, or calibration, it might make sense for you to just stick with hand guiding. As long as it doesn’t require extra investment on your part — i.e. it’s a standard feature for your robot — then you really have nothing to lose by trying it out.

However, if any of the benefits of TwinTrack are important to you, it makes sense to look into it as a possibility.

Your choice of robot programming tool will be an important one so you owe it to yourself to get it right.

Which factor is most important for your robot application? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.