There are various CNC toolpath software packages on the market. But, not all of them are suitable for robot machining.

What are your options if you want your generated toolpaths to control a robot instead of a conventional CNC machine?

A few key software features are necessary if you want to control your robot easily and efficiently. Plus, there are some important considerations you will need to make if you want to get the most from your machining robot.

Here’s a quick guide to CNC toolpath software for robot machining.

What is a CNC Toolpath?

A CNC toolpath is the path that a computer-controlled cutting tool takes through a workpiece. Toolpaths must be planned with care to ensure the correct cutting rate for the machined material to achieve the desired surface finish.

The traditional way to program CNC toolpaths was to code them by hand using G-Code, a specialist programming language for machining. This programming language still underlies most machining operations today.

However, these days it is far more common that you use Computer-Aided Machining (CAM) software to automatically generate the required G-Code out of the 3D models of your part. This G-Code is then sent to your CNC machine which uses the instructions to machine the part.

Toolpaths for CNC: How They Fit With Robot Machining

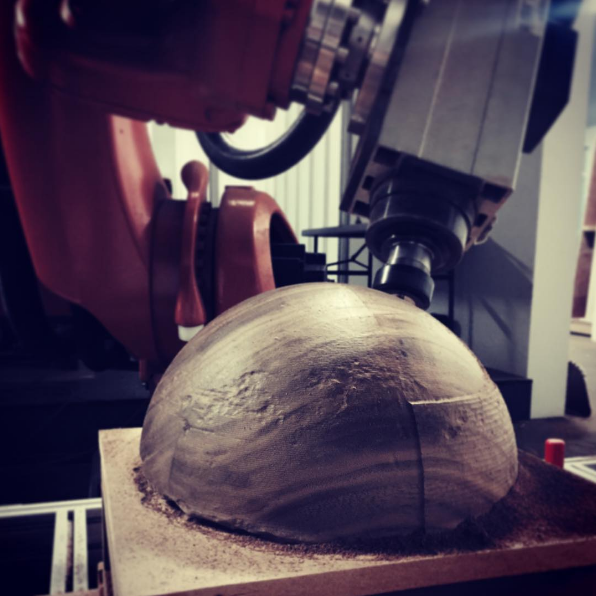

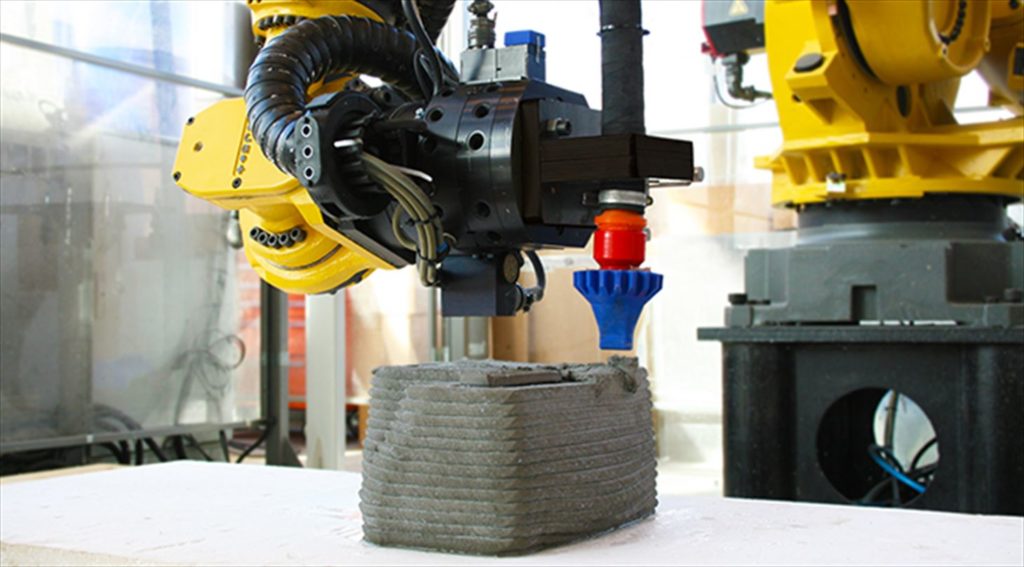

Robotic machining is a form of computer-controlled machining where a robot is used in place of a conventional CNC machine. For certain machining tasks, it has some advantages over conventional machines including improved flexibility and the ability to work with larger workpieces.

When you are programming your robot for a machining task, you will likely use the same process as with conventional CNC machining.

This process is:

- Generate computer models of your part in your preferred CAD program.

- Use CAM software to generate the CNC toolpath in G-Code from those models.

- Export this toolpath to your robot or CNC machine.

CNC machines natively understand G-Code so this third step is usually extremely straightforward. It just involves copying the generated G-Code file to the machine.

However, robots do not natively understand G-Code. They are usually programmed using the manufacturer’s proprietary programming language.

As a result, you need to use a dedicated robot programming tool to quickly and effectively program your robot for machining tasks.

What CNC Toolpath Software is Available

There are various options for CNC toolpath software, ranging from free software (often targeted at hobbyists) to expensive packages for industry.

In general, the tools come under the category of CAD/CAM software, which means that they can be used to both build the 3D models of your parts and generate the G-Code toolpaths.

The problem with most software is that it does not contain support for robot machining. This means you have to do the extra work to integrate the program with your robot… and this work can be significant!

Unless you pick a tool that makes robot machining easy…

An Integrated Robotic CNC Toolpath Software

There is an option if you are looking for an easy, reliable tool for robot machining.

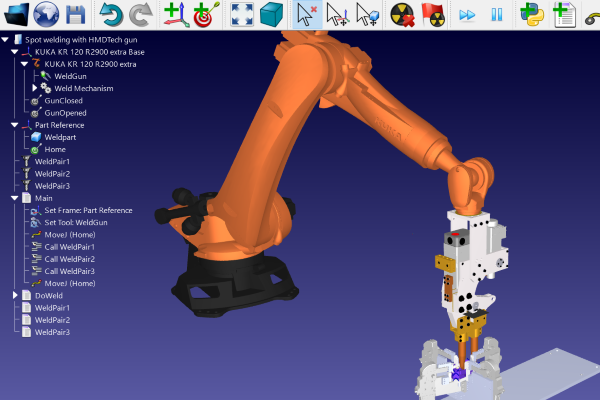

RoboDK is a dedicated robot programming tool that supports hundreds of robot models from dozens of robot manufacturers.

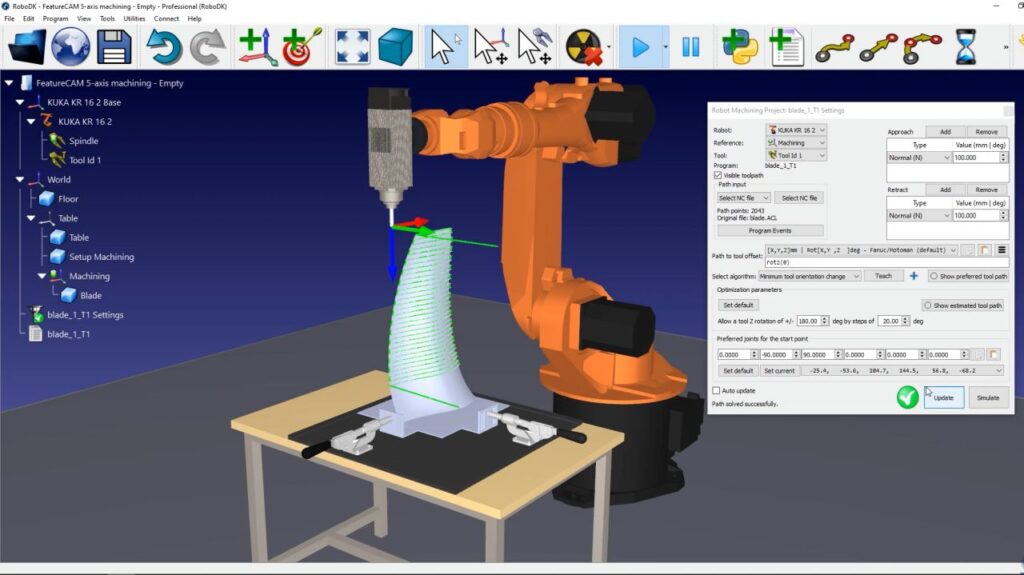

Among its many features and supported applications, RoboDK contains an integrated machining wizard that allows you to work with CNC toolpaths within the software itself.

It also has native plugins for many popular CAD/CAM packages. This means you can add it easily into your production workflow.

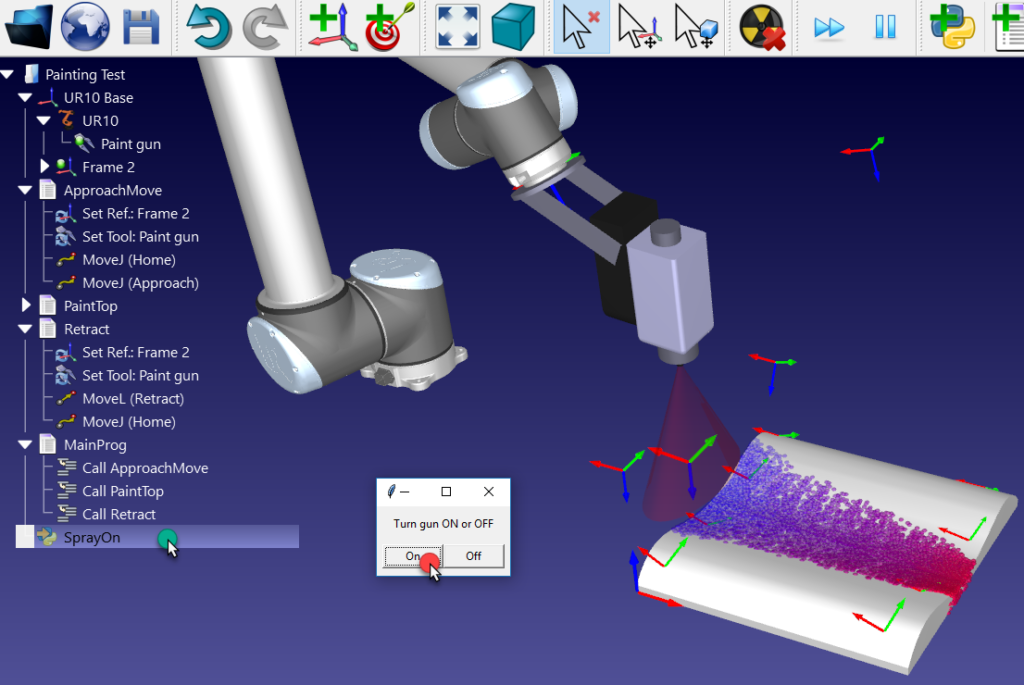

You simply load your generated CNC toolpath into the machining tool and RoboDK will automatically generate a robot program for the machining operation. You can also use the software’s simulation capability to test the operation before you send the program to the physical robot.

3 Very Useful Features of RoboDK’s Machining Tool

Some distinctive features of RoboDK make it especially useful as a tool for robot machining.

The 3 top features that you are likely to use are:

Visualize the Toolpath

There is a whole category of software tools called “G-code simulators.” These exist so that you can visualize your generated toolpath before you send it to the CNC machine itself.

With RoboDK, there is no need for an extra G-Code visualization tool. The integrated machining wizard generates a visualization of the toolpath right inside the RoboDK itself. It also shows how the robot will move along this toolpath.

Collision Avoidance

One difference between robots and CNC machines is that robots are more in danger of collisions. Due to their flexible workspace, they can collide with the environment, with the workpiece, or with other objects within their workspace.

RoboDK automatically detects collisions that might occur during your machining task. As this is done during the simulation stage, it allows you to correct for these collisions before the program is sent to the physical robot.

Solves Singularities

Singularities are a unique problem for robots and other complex mechanical structures. They occur when the robot’s program tries to instruct the robot to make a physically impossible move. A few different types of singularity can occur.

By programming your machining task with RoboDK, you can solve singularities before they become a problem. The software automatically detects and solves singularities.

How to Visualize Your CNC Toolpath With the Machining Wizard

The best way to start using RoboDK’s machining wizard is to download a free trial copy on our download page.

You can find examples of robot machining projects, video tutorials, and detailed practical guidance on our documentation page.

What CNC toolpath software do you currently use? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram, youtube or in the RoboDK Forum.