https://drive.google.com/file/d/1qaxofhI...sp=sharing

https://drive.google.com/file/d/134P2WEC...sp=sharing

https://drive.google.com/file/d/1VVz0GD1...sp=sharing

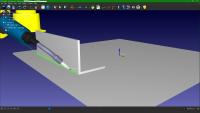

Fanuk sinusoidal weaving

Hi everyone

Our company recently acquired RoboDK.

And now I have questions about the organization of the welding process

We use FANUK robot (AM120IB 30A B PPL)

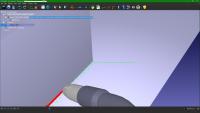

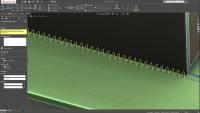

In manual learning mode, we used the "wave sine" function to get sinusoidal motion along the weld

At this moment, I am trying to get this trajectory using Solidworks tools.

I am interested in precision trajectory tuning.

If I use Solidworks tools I have two problems - I spend a lot of time on this and the robot program is very large (more than 100KB for one seam)

Are there some similar tools in the RoboDK program for obtaining similar results without wasting to mch time and memory resources?

https://drive.google.com/file/d/134P2WEC...sp=sharing

https://drive.google.com/file/d/1VVz0GD1...sp=sharing

Fanuk sinusoidal weaving

Hi everyone

Our company recently acquired RoboDK.

And now I have questions about the organization of the welding process

We use FANUK robot (AM120IB 30A B PPL)

In manual learning mode, we used the "wave sine" function to get sinusoidal motion along the weld

At this moment, I am trying to get this trajectory using Solidworks tools.

I am interested in precision trajectory tuning.

If I use Solidworks tools I have two problems - I spend a lot of time on this and the robot program is very large (more than 100KB for one seam)

Are there some similar tools in the RoboDK program for obtaining similar results without wasting to mch time and memory resources?