Food printing could be the next thing in high-end restaurants. Here’s how one of our users achieved 3D printed food with a robot, and how you can do the same.

At first glance, 3D printed food might seem quite an impractical application. 3D printing takes ages, doesn’t it? It can take hours to print even a tiny object. Who has the time to wait hours for a robot to print you a pizza!?

And yet, 3D printed food is becoming quite popular. It allows chefs to make complex and intricate food shapes like never before. You can even 3D print food with a robot, as one of our RoboDK users did.

It looks like 3D printed food will be part of the future of high-end gastronomy. According to the annual 3D Printing Conference, supermarkets are already testing 3D print customized cakes and restaurants are offering 3D printed desserts. People have successfully 3D printed a whole range of different foods, including mushroom, chocolate, red pepper, spaghetti, and pizza.

Case Study: 3D Food Printing With RoboDK

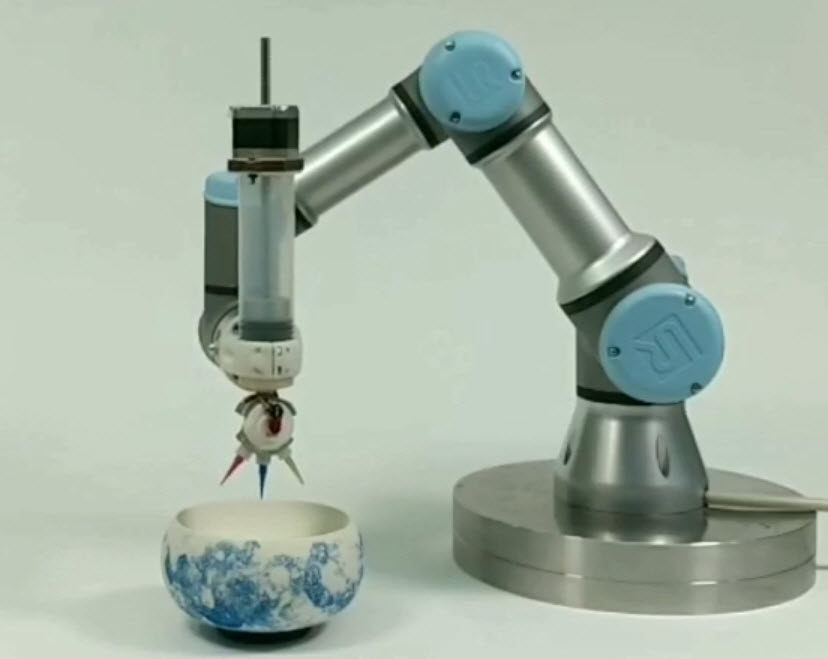

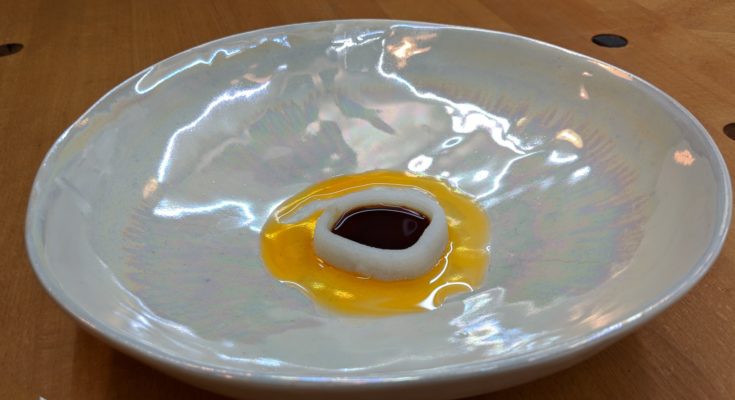

Here, you can see a video of a project perfomed The Hebrew University of Jerusalem where RoboDK was used to control a UR3 Universal Robot for 3D printing.

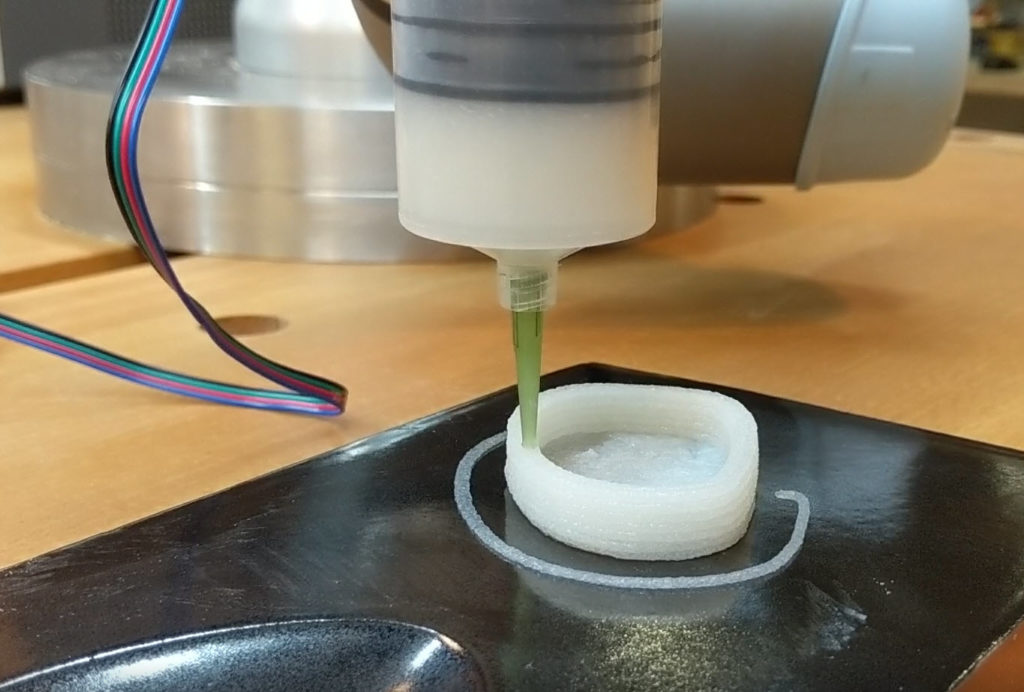

The setup included a syringe extruder (see below for more information on these) which printed the liquid food into intricate shapes. The food then set into a solid gel and sauces were added by hand.

How 3D Printed Food Works

The principle of 3D printing food is fundamentally the same as printing any other material. It is an additive manufacturing process where the material is built up layer-by-layer. The thick liquid material is extruded in a small stream onto a printing bed and a robot moves the extruder around the printing bed to draw the desired shape of the current layer. Once that layer has set, the next layer begins.

The most common materials for 3D printing are ABS and PLA plastic. These have good melting and hardening properties. As a result, the printed objects have very similar material properties to the raw material.

One of the challenges of food printing is that food does not have reliable material properties. Different foods melt at different temperatures, heat changes their material properties, and they are subject to spoilage.

Engineers have come up with various ingenious methods for extruding food. Three common methods are:

- Syringe extruders — This is the method used in the video. It involves loading the liquid-paste food into a capsule which is loadied into a large syringe. The extruder can gradually push the liquid out. The method works with a whole range of different foodstuffs from mashed potato to bread dough.

- Melting extruders — These work in a similar way to the plastic extruders in normal (i.e. non-food) 3D printers. They take solid foodstuffs — usually chocolate — and melt them before printing through a heated extruder. The MMuse Chocolate 3D printer is one example.

- Granular material binding — This involves using grains of food — usually sugar — and binding them together in the desired pattern by selectively melting and recrystallizing the material using heat and water. In this way, it is closer to stereolithographic printing than additive printing. The ChefJet 3D printer is probably the best example. It can print amazing full-color structures from sugar.

In most cases, you will use a syringe extruder if you want to print food. They are compatible with the most diverse range of foodstuffs and are easy to build and use.

5 Components You Need to 3D Print Food With a Robot

If you want to replicate the 3D food printing success from the video, you will need a few different components.

If you want to replicate the 3D food printing success from the video, you will need a few different components.

- The Robot — Theoretically, you could use any size of robot for 3D printing food. It all depends on how big your food needs to be. Tiny robots (e.g. Meca500 or UR3) can produce small edible decorations, while larger robots could potentially build a full-sized gingerbread house (if you had a big enough oven, of course).

- An Extruder — The type of extruder will depend on which foodstuff you are printing. Syringes are the most versatile.

- A Printing Material — The food! You will have to process the food so that it is printable by the machine. This usually means making it a thick liquid paste so that it can be dispensed by the syringe. If you want the food to set into a jelly-like solid, you will need to add some sort of hydrocolloid (here’s my favorite hydrocolloid recipe collection).

- A 3D Model — You will need a digital model of the pattern that you want to print. This should be in a CAD format which will be converted into a 3D printing path by your software.

- A Software Solution — You can make life easy for yourself by picking the best software solution for the job. RoboDK includes a 3D printing wizard which automatically generates a robot path for any robot.

Flavor: The Most Important Component

Pretty food is all very well. However, your decoration will be worth nothing if your food doesn’t taste great.

In fact, I would go one step further. I would say that your 3D printed food has to taste even better than great. It needs to taste absolutely amazing!

There’s nothing more disappointing than a spectacularly-decorated meal that tastes bland.

Food Ink was the first pop-up restaurant to serve all 3D printed food. You can bet that they spent just as long making the food taste amazing as they did designing the 3D printing patterns. It takes a lot of experimentation to get the right balance between flavor, texture and design.

How to 3D Print Food With RoboDK

If you want to print food with a robot for yourself, the process is very similar to normal 3D printing with a robot.

Check out our 3D printing demonstration to see how easy it is to do with RoboDK.

Then, go to the relevant documentation pages for instructions on how you can achieve it for yourself.

Would you eat a meal that was 3D printed by a robot? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram or in the RoboDK Forum.

It’s going to be end of mine day, however before end I am

reading this great post to improve my know-how.