Do you wonder if 3D manufacturing simulator software could improve your processes? It might…

But how will simulation help? How can you ensure that you get the most from your simulator without wasting time?

Here’s a clear and concise guide to 3D simulator software for manufacturing businesses.

Simulation software is a thriving and growing market. According to market reports, the simulation software is expected to reach a market value of $26.9 billion over the next 4 years.

There are some very compelling reasons to adopt simulation into some of your manufacturing processes. Firstly, you need to understand what it is and how it can apply to your specific business.

What is 3D Simulator Software and Do You Need It?

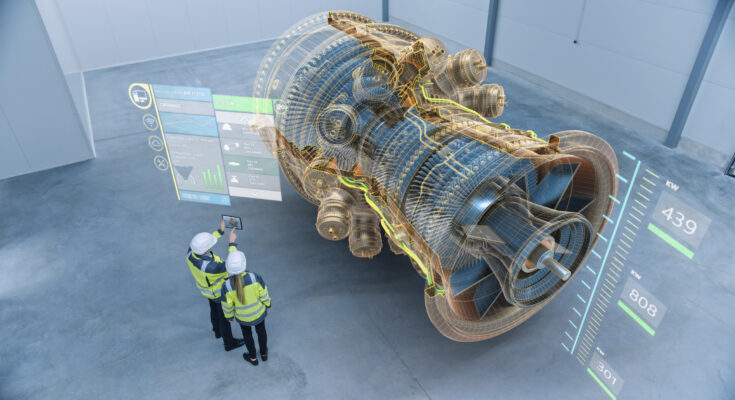

Simulation involves using a computer program to model certain aspects of a manufacturing environment. Many systems and processes can be simulated.

Some types of simulation software merely use computer algorithms with very little visual feedback. Moreover, 3D simulation software renders the results of the simulation in a three-dimensional visual model. This is making it easier to understand the data.

However, you might wonder if simulation is really worth it for your manufacturing processes.

Wouldn’t it be quicker just to build the physical system? That way, you might think, you wouldn’t have to mess around with software beforehand. You would immediately start to gather real-world data.

The fact is that you can’t afford not to use simulation.

As we’ll see below, there are many great benefits to using simulation software in your manufacturing processes. Your competitors are already using 3D simulators and gaining those benefits.

5 Types of Simulation for Manufacturing

There are various types of simulation that you can use in manufacturing. Some are 3D simulators while others have simpler visual interfaces with powerful algorithms behind them.

Here are 5 common types of simulators you might use:

1. Robotic Simulation

Robotic simulation allows you to design and simulate automated applications involving robot systems. A good robot simulator will support many robot brands and allow for simple but powerful simulations.

RoboDK is an example of a feature-filled robotic simulator.

2. FEA Simulation

A common simulation step during product design, finite element analysis (FEA) allows you to test the effect of physical stresses on materials.

In addition, good FEA simulation software makes it easy for you to proactively improve your designs.

3. CAD/CAM Modeling

An extremely common form of 3D software, CAD/CAM packages allow you to design your products in a computer environment.

Computer-aided design (CAD) functionality focuses on the initial design phase. Computer-aided manufacturing (CAM) functionality lets you simulate the manufacturing process.

4. Discrete Event Simulation

Discrete event simulation (DES) is used to optimize a whole range of manufacturing processes including production process design, facility layouts, and process parameter optimization.

Some DES software packages have 3D interfaces while others only support text-based input and output.

5. Intelligent Simulation

Artificial intelligence (AI) is everywhere these days. This is also true in manufacturing simulations where the use-cases for AI are growing steadily.

Intelligent simulation uses AI to improve the quality of simulation for many different applications including product development, management, and automation.

How to Start Using Manufacturing Simulation the Easy Way

How can you start using simulation software in your manufacturing business?

A good place to start is to remember that you don’t have to simulate everything. In fact, trying to simulate everything would be a bad idea — it would waste a lot of time and make your operations unnecessarily complex.

It’s much easier to identify a particular part of your process that you want to improve and focus exclusively on simulating that.

Thus, a good candidate is robotic automation.

Manufacturers are often hesitant to start using robots. Furthermore, they are unsure how the robot will fit in with their existing processes.

A good robot simulator lets you see the robot in action on a specific target application. It’s an easy, low-cost way to validate that robotic automation is the right choice before you invest in any physical robotic hardware.

7 Great Benefits You’ll See When You Use 3D Simulation

How will adding 3D simulation make your operations better?

Here are 7 great benefits you can see when you start using manufacturing simulation software:

- Faster time to market — Simulation is almost always faster than testing ideas out in the real world. This means you can smooth out potential problems early and get your new products and updates to market much faster.

- Less costly downtime — Working with a simulation means you are not taking your physical processes out of production to make changes. This is why robotic simulation and offline programming can save you lots of costly downtime.

- Easier and quicker to change out components — Changeovers are a huge source of wasted time and resources in manufacturing environments. A robot simulator, for example, allows you change your robot’s task very quickly or even switch it with a completely different robot.

- Reduced inventory — Excess inventory is one of the major wastes in manufacturing. Simulators help you to optimize your material handling processes, reducing costly inventory buildup.

- Better information about your processes — The more data you gather about your process, the better you can optimize those processes. Simulators start giving you this valuable data from early on in the design process.

- Spot and rectify inefficiencies — It’s often hard to see problems and inefficiencies in an already-running system. Simulators make it easier to spot and debug inefficiencies early. For example, RoboDK will automatically flag up singularities, which are hard to spot in a physical robot.

- Use fewer resources to run your facility — The more you leverage your simulations, the less likely you are to have people running around your manufacturing facility trying to reactively fix problems. This makes your facility more efficient overall.

Which Type of 3D Simulator to Try First

Which of the various types of manufacturing simulators should you start using first?

This really depends on your situation. Try to identify which aspects of your manufacturing process are most inefficient and which will have the biggest impact by improving the process.

Finally, if you are implementing robotic automation, check out our simulator page to find out about robot simulation.

What aspect of your manufacturing process would you like to simulate? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.. Also, check out our extensive video collection and subscribe to the RoboDK YouTube Channel