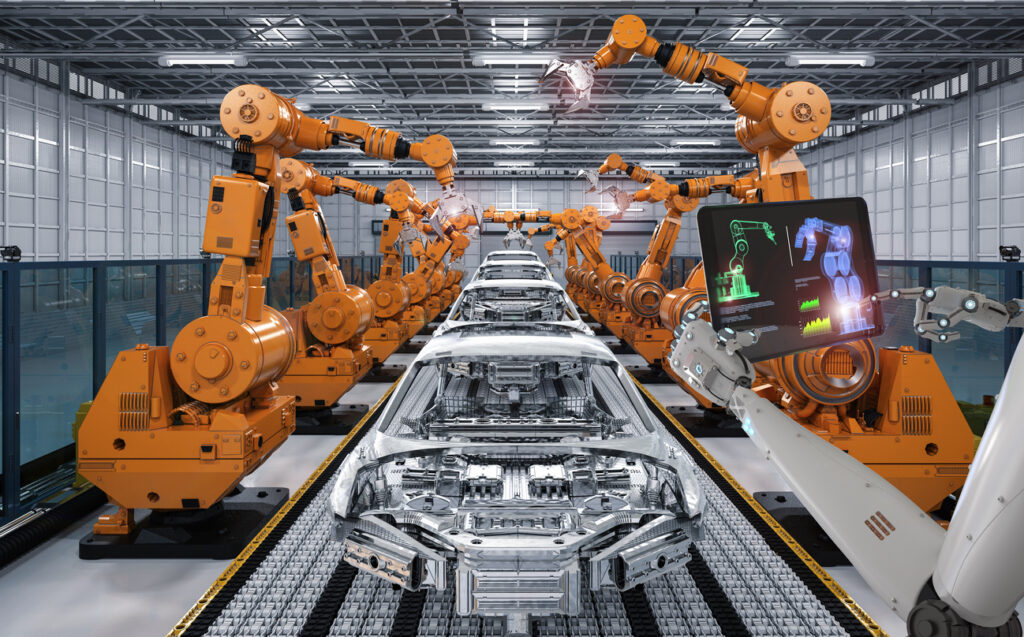

The rise of Industry 4.0 has ushered in a new era of industrial automation characterized by the convergence of digital technologies and physical manufacturing processes. At the heart of this revolution are industrial robot arms, dynamic machines that redefine how businesses operate and shape the future of automation.

In this blog post, we will explore the transformative power of industrial robot arms within the context of Industry 4.0, and how they are propelling the manufacturing industry forward.

Enabling Connectivity and Collaboration in Smart Factories

As Industry 4.0 emphasizes the integration of cyber-physical systems, industrial robot arms serve as the backbone connecting the physical and digital realms. These intelligent machines have advanced sensors and software, enabling them to communicate, collaborate, and coordinate seamlessly with other devices, systems, and human workers.

By enabling connectivity and collaboration, industrial robot arms facilitate the realization of intelligent factories where automation systems work harmoniously, sharing real-time data and optimizing production processes.

Robot Arms: Enhancing Productivity, Flexibility, and Quality

Industrial robot arms bring a multitude of benefits to the manufacturing landscape. With their remarkable precision, speed, and repeatability, these machines can perform various complex tasks with unmatched efficiency.

Their ability to quickly adapt to changing production needs makes them highly flexible and versatile. Moreover, industrial robot arms improve product quality by eliminating human error and ensuring consistent and precise operations. By leveraging these capabilities, businesses can achieve enhanced productivity, greater agility, and high product quality.

Leveraging Real-time Data for Predictive Maintenance and Optimization

In the era of Industry 4.0, data is king. Industrial robot arms play a crucial role in collecting and analysing real-time data from their sensors, allowing for predictive maintenance and optimization of production processes. Moreover, it enables proactive maintenance by continuously monitoring their performance and detecting signs of potential issues, reducing downtime, and minimizing costly breakdowns.

Remote Monitoring and Control for Efficient Operations

Industrial robots can be remotely monitored and controlled, offering businesses a new level of operational efficiency. With centralized management and remote accessibility, companies can oversee and coordinate multiple production sites from a single location. This remote-control capability enables rapid response times to potential issues, reduces the need for on-site presence, and streamlines maintenance and troubleshooting procedures. As a result, organizations can achieve cost savings, increased uptime, and more efficient allocation of resources.

Successful Case Studies

Below are several real-world case studies that exemplify the successful implementation of industrial robot arms and the tangible outcomes accomplished by businesses:

Tesla’s Gigafactory

Tesla, the electric vehicle manufacturer, implemented many industrial robot arms in its Gigafactory for automating various production processes. These robots are used for tasks like welding, painting, and assembly.

By using robots, Tesla significantly increased production efficiency, reduced defects, and improved product quality. Additionally, its implementation also improved worker safety by automating hazardous tasks.

Amazon’s Fulfillment Centers

Amazon: the e-commerce giant, employs thousands of industrial robot arms in its fulfillment centers. These robots are responsible for picking, packing, and sorting items for shipment. By using robot arms, Amazon has been able to greatly speed up order fulfillment, leading to faster delivery times for customers. They work alongside human workers, allowing for a more efficient and streamlined operation.

BMW’s Production Line

BMW, the automotive manufacturer, incorporated industrial robot arms into its production line for tasks such as welding painting, and assembly. The robots work collaboratively with human workers, enhancing productivity and precision. BMW has reported improved production quality, reduced cycle times, and optimized resource utilization through the implementation of robot arms.

The Future of Industrial Robot Arms in Industry 4.0

The future of industrial robots within the Industry 4.0 landscape is promising. As technologies such as artificial intelligence, machine learning, and advanced sensors evolve, robot arms will become even more intelligent and autonomous. This will lead to adaptive decision-making, enhanced human-robot interaction, and improved safety measures. Integrating them with other emerging technologies, such as augmented and virtual reality, will expand their capabilities, allowing for more immersive programming, simulation, and training experiences.

Conclusion

Industrial robot arms are undeniably driving the future of automation in the Industry 4.0 era. Their connectivity, collaboration, and adaptability empower businesses to create intelligent, efficient, and connected manufacturing environments. By embracing these technologies, companies can gain a competitive edge, achieve higher productivity and reduce costs. And stay ahead in the rapidly evolving landscape of industrial automation.

To fully unlock the potential of industrial robots in your manufacturing processes, visit robodk.com. RoboDK offers cutting-edge software solutions that streamline robot programming, simulation, and optimization. With RoboDK’s intuitive platform, you can unleash the full capabilities of industrial robots.

Remember, the future of manufacturing is here, and industrial robots power it. Take advantage of the opportunity to revolutionize your operations and stay at the forefront of innovation.

Follow us on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.. Also, check out our extensive video collection and subscribe to the RoboDK YouTube Channel