ABB is one of the top robot brands in the world – being one of The Big 4 robot companies. If you use ABB robots, this spotlight guide is for you!

ABB has an impressive presence in many international markets. In fact, you can find ABB products on all the continents of the world – even Antarctica! ABB Robotics has a 10.04% market share in the engineering and manufacturing market.

In this Spotlight on ABB, we’ll look at how you can program ABB robots easily for your chosen application.

The ABB Story: What Sets ABB Robots Apart

The history of ABB really begins when with the merger of two significant engineering companies.

Brown, Boveri & Cie (BBC) was an innovative Swiss-based electrical engineering firm specializing in the development of steam turbines and other power sources. Elektriska Aktiebolaget (ASEA) developed Sweden’s first three-phase transmission system and built the country’s first nuclear power plant. In 1988, the two companies combined to become ASEA Brown Boveri (ABB), bringing together over 200 years of expertise.

ABB Robotics began in 1998, with the launch of the company’s FlexPicker robot. It revolutionized industrial robotics by allowing advanced high-speed picking and packing applications.

Now, ABB is a leading global technology company with a focus on robotics and automation technologies across a large range of industries. The company has over 110,000 employees in more than 100 countries around the world and an annual revenue of over $28 billion.

The company says “We envisage a future where the physical and digital worlds merge, making operations safer, more intelligent, and more productive.”

What Industries are ABB Robots Used In?

ABB robots are used in a wide range of industries, including automotive, construction, education, electronics, healthcare, logistics, and metal fabrication.

For example, in the automotive industry, ABB robots are often used for tasks like welding, painting, and inspection. In construction, manufacturing companies use them for heavy lifting and precision cutting of wood and metal. In the electronics industry, the company’s delta robots are often used for assembly and pick and place tasks.

There are so many potential industries where ABB robots are used, it’s very likely that you can find various applications that work for you.

3 Example Applications for ABB Robots

There are so many applications areas where you can apply ABB robots, including palletizing, welding, painting, assembly, pick and place, material handling, and many more.

Here is a spotlight on just 3 of these application areas, along with examples of ABB robot models that suit them:

1. Palletizing

Palletizing is an increasingly popular robotic application that involves stacking items onto pallets for shipment. It is a critical step in supply chain logistics.

ABB’s IRB 460 robotic palletizer is, according to the company, the world’s fastest palletizing robot. It can achieve up to 2,190 cycles per hour with a 60 kg load, 15% faster than its closest competitor.

See the IRB 460 in RoboDK’s Robot Library.

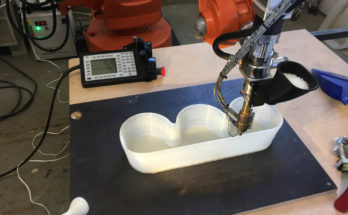

2. Welding

Welding involves joining two or more pieces of metal together to form a strong bond. As welding processes have become more complex, robot welding has grown in popularity. Professional welders are also now more scarce than ever.

ABB’s IRB 1520ID welding robot is designed to maximize efficiency in welding operations. It comes with an integrated hose package that allows easy routing of all the necessary media for welding (e.g. power, welding wire, shielding gas).

See the IRB 1520ID in RoboDK’s Robot Library.

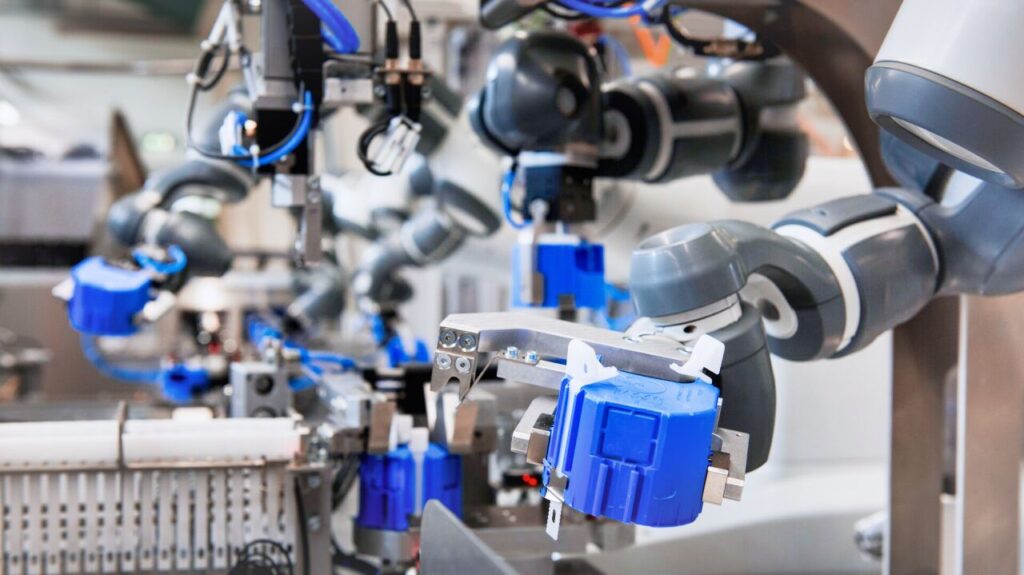

3. Material Handling

Material handling is a wide-ranging category, including tasks like loading, unloading, sorting, and transporting. Indeed, robots can be used for various material handling tasks to increase productivity and consistency.

ABB’S IRB 1200 material handling robot offers users high-level flexibility. Compact and with ample working areas, the robot is easy to use for material handling tasks.

See the IRB 1200 in RoboDK’s Robot Library.

Options for Programming ABB Robots

All in all, whatever application you choose, you need to program your robot easily and in a way that integrates with all your other processes.

There are a few options for programming ABB robots:

Brand Programming Language: RAPID

The RAPID programming language is ABB’s basic method for programming its industrial robots. It uses object-oriented programming and provides functionality to move the robot, compute mathematic functions, and handle inputs and outputs.

Teach Pendant Information

Teach pendants are the standard method for programming industrial robots. They require you to program the robot online, which means the robot must be taken out of operation for programming.

There are two teach pendants available for ABB robots the older legacy pendant and the FlexPendant. Both offer a graphical user interface and buttons for creating your program.

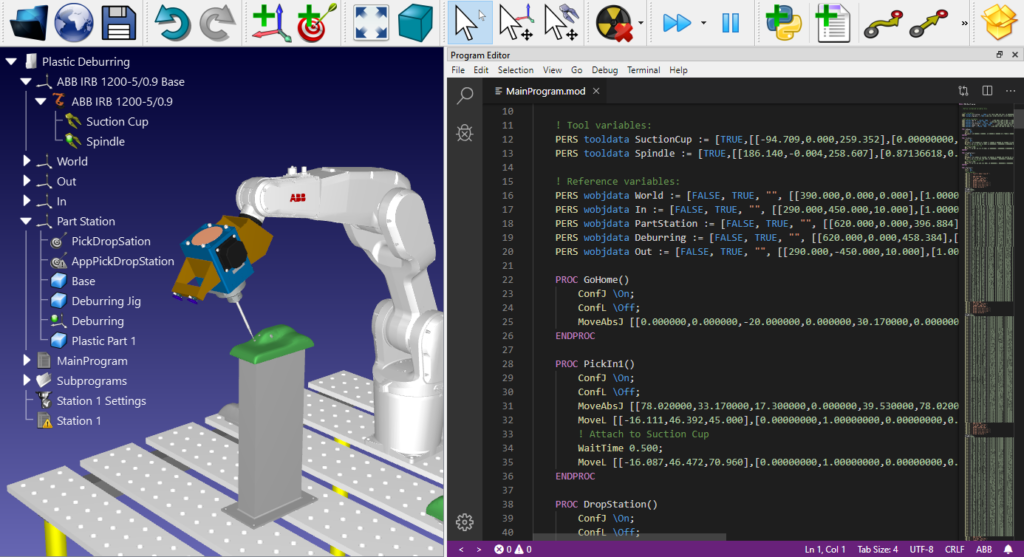

RoboDK

RoboDK is an offline programming and simulation software that works with a wide variety of robot brands. It is compatible with many ABB models, which you can find in the online Robot Library.

As an offline programming tool, you can program your robot with RoboDK without taking the robot out of production. No programming skills are required with the intuitive RoboDK graphical interface. Overall, you can even use the RoboDK API to program robots in your favorite programming language.

How to Program ABB Robots Easily with RoboDK

If you want to streamline the deployment process for your ABB industrial robot, it’s worth looking at using RoboDK for your programming.

RoboDK’s rich simulation environment makes it easy to quickly design robot programs and test them before you put the robot into production.

Finally, to get started, download a trial copy of RoboDK from our download page and load up your favorite robot model.

Which ABB robot do you use and for which applications? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.. Also, check out our extensive video collection and subscribe to the RoboDK YouTube Channel