Which robot applications are best suited for the electronics industry?

Robots are becoming extremely popular among electronic companies.

Recent estimates indicate that robot growth is even higher in the electronics industry than in the automotive industry, which has traditionally been the leader for robot use.

If you are looking to add robotic automation to your process, it can be hard to know which tasks are the best candidates.

Here are 15 applications that are well-suited to the electronics industry:

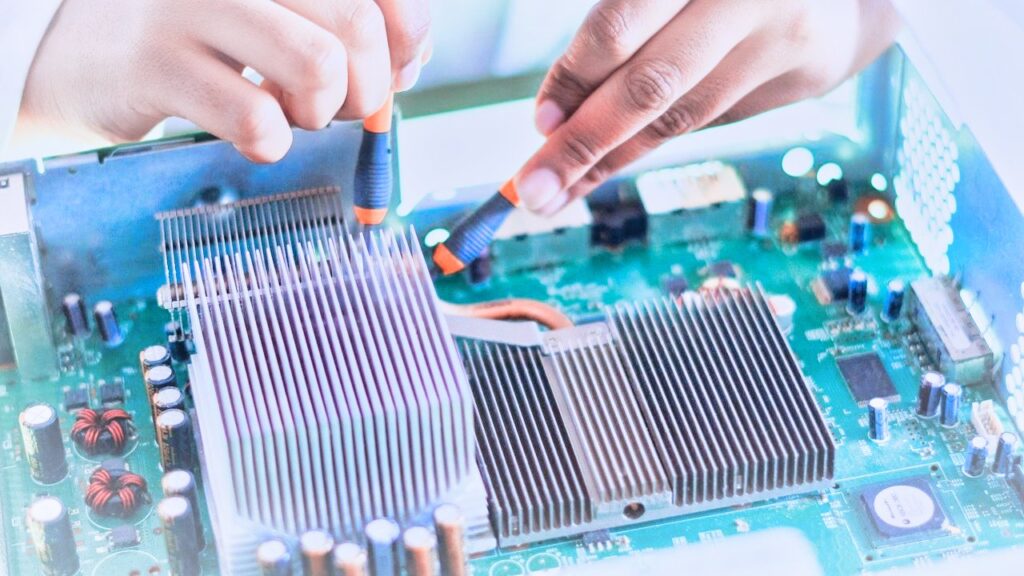

1. Assembling circuit boards

Classic application in electronics manufacturing, robots are perfect for circuit board assembly. Firstly, robots complete the task more consistently than a human operator would. As a result, the overall quality of your product can benefit.

For example, one of the most common robots used for fine assembly is the SCARA robot.

2. Quality Inspection

Inspection tasks can easily become a bottleneck in electronic manufacturing. For instance, inspection methods include simple manual visual inspection or more advanced inspection with sensors.

As a result, robotic inspection is a proven way to overcome the inspection bottleneck; both for data collection with manual analysis and fully automated inspection.

3. Stress Testing

Electronics that are designed to be hard-wearing often need to undergo some form of stress testing. For example, in “highly accelerated life testing” the product is tested to breaking point.

With that being said, you can use robots in stress testing because they can consistently apply physical forces to the product in a way that emulates real-world stresses.

4. Packing Products

Efficiently packing products is particularly important when you are producing electronics at high volumes. However, you can use robots for packing tasks for a whole range of needs. For instance: High-mix, low-volume operations all the way up to mass production.

One benefit of using robots for packing is that they are easy to reprogram to accommodate varied product lines.

5. Palletizing Boxes

The final stage of processing before your products leave the door is usually tertiary packaging in the form of palletizing.

For example, robots are perfect for palletizing tasks and are used extensively across industries, including in electronics.

6. Cleanroom handling

Many electronic manufacturing tasks require a cleanroom environment. This can be a problem when you have many human workers as they increase the contamination risk.

As a result, robots are ideal for cleanroom handling of products as they are extremely unlikely to contaminate the environment.

7. High-speed Pick and Place

One of the most well-known robotic applications in the electronics industry is pick and place.

For instance, you can use Delta robots for this application thanks to their ability to move at high speeds. However, SCARA robots are favored when there are space restrictions.

8. Dispensing adhesive

The electronics industry uses glue and other adhesives extensively. A common problem is maintaining consistency in the dispensing task. As a result, even small inconsistencies can lead to huge wastage over time.

To sum up, robots are perfect for dispensing tasks as they will apply adhesive consistently every time.

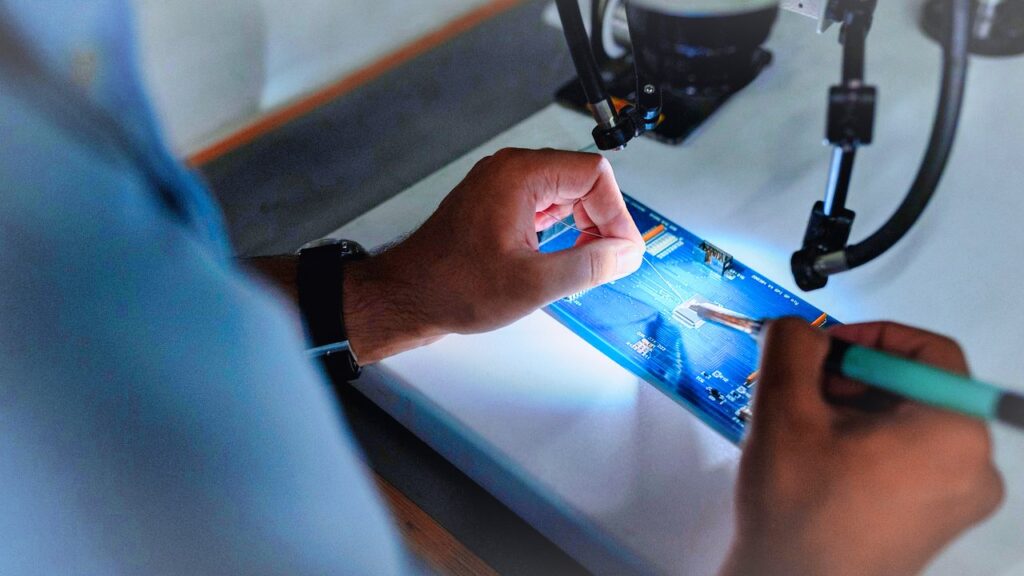

9. Soldering Components

Soldering is another task that requires a huge level of consistency. The conventional approach to soldering automation is to invest in large, expensive soldering machines.

Robotics offers a good alternative for automated soldering that is more adaptable to changes in your manufacturing process.

10. Etching Designs

Product personalization is increasingly popular and now customers often expect a degree of customization options. Robots offer a flexible way to customize electronic products.

For example, you can use a robot to etch a logo or design onto the product surface.

11. 3D Printing

Additive manufacturing has recently been transforming the electronics industry. It has been for both the design and prototyping phase of product development and the creation of the final products.

The possibilities of 3D printing with a robot are huge as they don’t have the same restraints as other 3D printing methods. For example, you can print products of any size you like with a robot.

12. Product Testing

It is common for electronic products to go through quality testing as part of the inspection process. Loading and unloading these machines is a difficult task for a human worker and does not add any value to the process.

A robot is a perfect option for tending product testing machines. This is because it leaves the person free to do more value-added tasks.

13. Spray Painting

When it comes to spray painting, product casings often need to go through a painting process before they go to market. Robotic painting is a well-established process and offers huge consistency benefits over manual painting.

14. Arranging Products

Many tasks require items to be laid out in regular order. For example, when you are baking printed circuit boards, the baking process is more consistent when the boards are laid out at regular intervals.

Unlike humans, a robot will always lay out the boards in exactly the same arrangement every time. As a result, this helps reduce wastage and quality issues caused by inconsistent baking.

15. Whatever You Can Imagine!

Can’t see your top application listed here?

There are many more opportunities for robotic automation than those in this article. If you think that one of your tasks might be suitable for your electronics company, you might be right!

A good way to test out your chosen application is to start by building it in a robot simulator, like RoboDK. Once you have decided that the application is workable, you can download the program directly to your robot.

What application would be most useful for your electronics company right now? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.