Have you ever wished you could just try out a new automation solution before you bought it? This is the idea behind virtual commissioning… and it may be the future of automation.

With virtual commissioning, you create a virtual model of your ideal automation solutions. You can test out those solutions, tweak them, and see how the automation technology will work with your specific process.

Commissioning any automation solution can be a complex and time-consuming process. With virtual commissioning, you can use robotic simulation technology to reduce both that complexity and the time. It avoids unnecessary downtime because you don’t have to take your existing machines offline to test the automation solution.

It seems likely that virtual commissioning will remain a core step in the automation process from now on. If you are looking for a way to streamline your deployment process, this option may be the answer.

What is Virtual Commissioning?

Virtual commissioning is the use of simulation technology to design, install, and test automation solutions before deploying the physical hardware into a manufacturing environment. For example, robotic simulation software can optimize a robot’s deployment without unnecessary downtime.

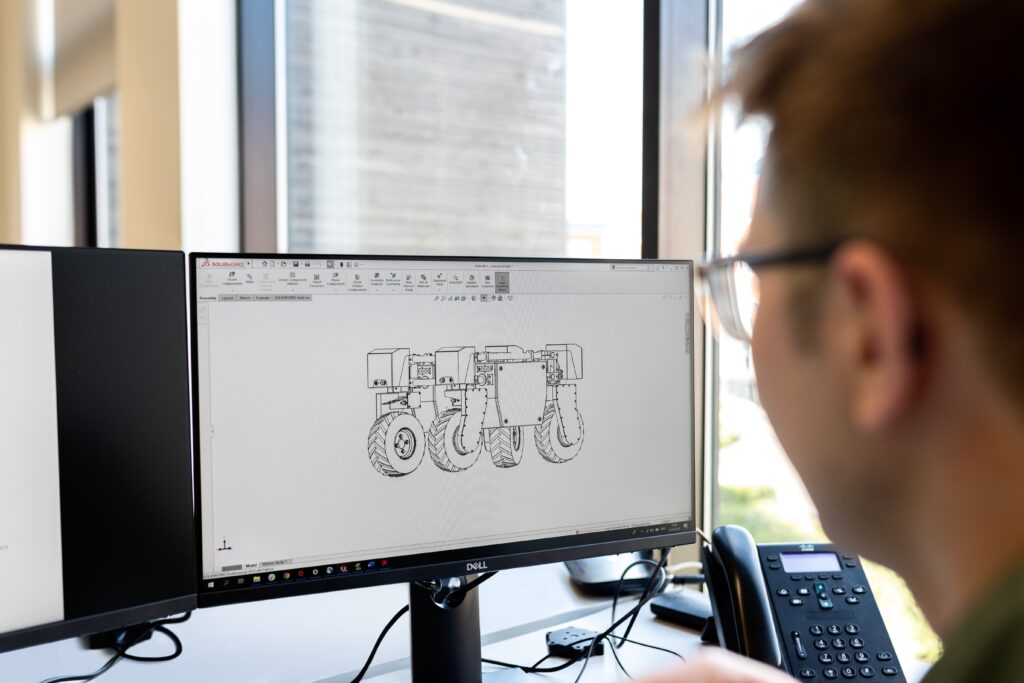

At the center of any virtual commissioning project is the simulation software. This software will include virtual models of any automation technology that might be used, as well as algorithms and functionality to test the operation of your system.

With robotic solutions, you can use the same simulation software to program the physical robot. RoboDK includes both simulation and offline programming functionalities. Once you have finished testing your deployment in the simulator, you can connect your physical robot and download the program directly to the robotic hardware.

The Difference Between Virtual and Traditional Commissioning

Is virtual commissioning really that different from traditional commissioning?

There are a few key differences between the two approaches to commissioning an automation project.

Traditional commissioning typically occurs on-site at the physical location where you will deploy the automation solution, such as your factory floor. You bring various physical tools and testing equipment for manual troubleshooting. This means that you may have to shut down some or all of your existing manufacturing processes for the duration of the commissioning project, which can be costly.

With virtual commissioning, you perform most of the deployment remotely, only coming on site at the very end.

Also, the traditional commissioning process often takes longer and requires a larger team for on-site implementation. With virtual commissioning, a small team or even a single person can do most of the deployment remotely.

How Does Virtual Commissioning Work?

The basic idea is to create a simulation or digital twin of your automation solution. This is a virtual model showing how the machine (or machines) will work in your process.

You use this virtual model to test out different scenarios to see how this will affect the automation solution. This helps you to optimize the solution before you take it to the physical environment.

Virtual commissioning with a robot simulator involves:

- Creating or importing virtual models of the relevant parts of your production line.

- Loading models of your robot from the Robot Library, along with any other equipment.

- Creating a robot program for your specific application.

- Optimizing the various aspects of your robotic solution before deploying it to your factory floor.

By approaching commissioning in this way, you can test your solution in a controlled, risk-free environment.

5 Unique Benefits of Virtual Commissioning

Here are 5 unique benefits of virtual commissioning:

1. Efficient Deployments

As virtual commissioning significantly reduces the need for time-consuming on-site activities, it improves the operational efficiency of your deployment. This helps you avoid costly downtime and makes your process more efficient overall.

2. Safer Automation

By simulating your automation project in a virtual environment, you can test potential hazards in a safe and controlled way. This helps you to avoid accidents and injuries that may occur in a traditional physical commissioning process. It also allows you to test hazardous limit cases that would be impossible to test with physical hardware.

3. Improved Team Communication

A simulator can provide a common platform for all your team members to view, understand, and suggest changes to your automation solution. This can help to improve communication and avoids potential misunderstandings. With RoboDK for Web, your colleagues don’t even need to install the software to view the simulation.

4. Flexibility to Changes

One significant benefit of virtual commissioning is that it is easy to make changes or adjustments to your production process. You can quickly test new ideas in the simulator, safely knowing that you are not disrupting your production.

5. Better Understanding of the Solution

Finally, developing your automation solution in a simulator allows you to better understand how it works. By “playing” with the technology in the virtual environment, you will quickly gain a working knowledge of its possibilities and limitations. This helps you make better use of the technology in the real world.

Will Virtual Commissioning Change Automation?

With the ever-increasing popularity of digital tools, it seems likely that virtual commissioning is here to stay.

Virtual commissioning helps to break down the entry barriers to automation that have restricted robot adoption for many manufacturers. It can allow anyone to quickly and efficiently deploy automation technologies to their manufacturing processes while reducing the risks associated with unnecessary downtime.

When you deploy your robotic technology with virtual commissioning, you increase your chances that the automation project will be a success. This makes robotics less risky as a solution and more valuable.

What questions do you have about virtual commissioning? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.. Also, check out our extensive video collection and subscribe to the RoboDK YouTube Channel