Flexible manufacturing allows you to quickly adapt your production lines to meet changing customer demands. But what could your company achieve by adding more flexibility to your processes?

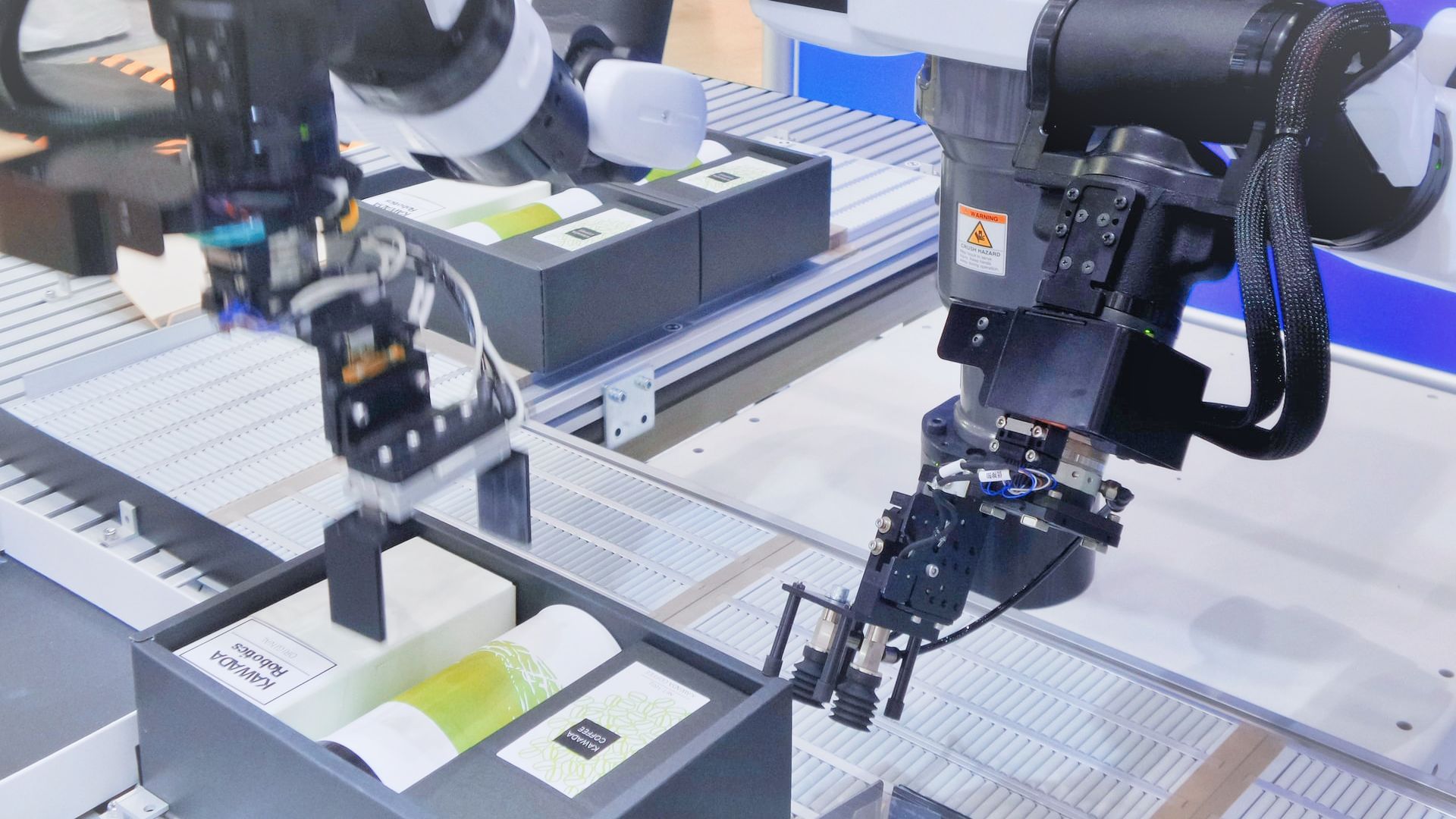

With the ability to rapidly reconfigure your equipment and processes, you can respond quickly to fluctuations in the marketplace. By using technologies like robots and the right programming software, you can increase flexibility in your manufacturing company.

Here are 20 things that flexible manufacturing can allow you to do:

1. Increase Efficiency

Flexible manufacturing lines can help you produce products more efficiently.

By using the same line to produce a variety of products, you can reduce or even eliminate the need for multiple production lines. This helps reduce both set-up and changeover times, and equipment costs.

2. Produce Products Faster

Whenever there are unexpected fluctuations in the marketplace, a flexible manufacturing approach allows you to adapt by quickly reconfiguring your equipment and production flows.

This flexibility means that you can get products out the door sooner following new orders. Unlike with conventional production, you don’t need to wait a long time for changeovers.

3. Use Smaller Batch Sizes

A significant advantage of flexible manufacturing is that it enables you to produce smaller batches of products at a time.

Small batch sizes help to reduce the costly buildup of inventory. They also allow you to test new market opportunities with a limited amount of product.

4. Respond to Customer Demands

The quick response times made possible by flexible manufacturing allow you to respond quickly to changing customer demands.

In the current market, often the company that moves first wins a significant competitive advantage. Flexible manufacturing can help you achieve this first-mover advantage.

5. Change Product Designs

With conventional manufacturing, changing a product design can be a difficult, lengthy, and costly process that requires you to invest in new technology.

A flexible manufacturing approach means that you rarely need to invest in new equipment to change product designs.

6. Improve Quality Control

The ability to reconfigure your manufacturing processes can also improve your quality control.

When you detect a quality issue, it’s much easier and quicker to change the process in a flexible system to eliminate the issue. This helps you to minimize the impact of that issue on future products.

7. Reduce Wastage

The small batch sizes that are typical with flexible manufacturing help you reduce the amount of wasted material you generate.

If something goes wrong in production — or there is less demand for a product than expected — small batches mean there is less wasted product for you to dispose of.

8. Save Energy

Flexible manufacturing can also be more energy efficient than alternative types of manufacturing.

By producing multiple products on the same line, you reduce the amount of energy required to operate your machinery.

9. Recycle and Reclaim Materials

You can also recycle and reclaim unused materials better with flexible manufacturing.

With advanced tool management strategies (such as flexible tool reuse), you reduce the wastage that is created by elements of your manufacturing process.

10. Improve Job Satisfaction

One advantage of flexible manufacturing is that it can create more interesting, rewarding work for your employees.

The higher-paced environment of a flexible manufacturing operation means that workers handle a wider range of tasks, better using their cognitive skills.

11. Work Safer

The automation technology that is core to flexible manufacturing can also make people’s work safer.

Automation helps to move people away from dangerous materials and machinery. This creates a safer work environment and reduces the risk of accidents.

12. Improve Sustainability

By optimizing the operation of your manufacturing processes, you can also reduce the amount of pollution they generate. This improves your sustainability as a company.

Various world-leading companies are now using sustainability as a market differentiator, including Amazon, Dell, and Apple.

13. Flexible Schedule Maintenance

Adding flexibility to your production lines also makes it easier for you to schedule maintenance and repairs in a way that suits you.

With flexible manufacturing, you can more easily reroute jobs through other processes while you are repairing a particular machine. This helps reduce the impact of maintenance on your production.

14. Manage Your Workforce

Flexible manufacturing also means flexibly managing your workforce.

By making flexibility a core driver in your business, you can more easily redeploy workers to different tasks as needed. This helps you to respond quickly to changes in demand.

15. Collaborate Better

Collaboration and communication are at the core of flexible manufacturing.

This approach to manufacturing requires that you, your teams, and your suppliers are all collaborating well. This can help to improve communication and can lead to the development of new ideas and processes.

16. Innovate More

The ability to quickly reconfigure your production lines makes it easier to experiment with new project ideas.

These days, innovation is critical in manufacturing. As the world continues to change rapidly, it’s important that we keep innovating so we can keep up.

17. Boost Morale

Introducing flexible manufacturing techniques can contribute to an improvement in employee morale.

By making production more collaborative, employees can feel that they are more able to contribute to the future of the company and that their work is valued.

18. Satisfy Customers

Customers increasingly expect products to be highly personalized and available as quickly as possible.

With a flexible manufacturing approach, you can deliver on these requirements by altering your production processes to suit the needs of your customers, rather than the needs of your technology. This improves customer satisfaction.

19. Shorten Time-to-Market

The quicker you can get new products to market, the sooner you can start selling and generating revenue.

Because you can produce products more quickly and efficiently with flexible manufacturing, you can shorten the time to market without harming product quality.

20. Create Competitive Advantages

Finally, flexible manufacturing set your company apart from others in your industry. It can give you an important competitive advantage in the modern market.

By setting up your production processes to respond quickly to change, you improve your ability to weather whatever storms the market throws at you.

With software like RoboDK, you can incorporate robotic automation into your processes, helping you to become more flexible.

What benefits do you see with flexible manufacturing? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.. Also, check out our extensive video collection and subscribe to the RoboDK YouTube Channel