When you invest in a new automation solution, you want to make sure it is reliable, safe, and serves the purpose you need. Automation validation is the process of testing automation systems to ensure they perform as expected.

There are various methods of automation validation, depending on the type of automation you are using. For example, software-only automation – such as that used to automate administrative tasks – may have both software-based and human testing.

For robotic automation, an effective tool for validating your automation designs is robot simulation. This enables you to test your robotic system in a controlled virtual environment before you deploy robots to the real world.

Let’s explore how robot simulation can help you optimize your automation solution before you even touch a physical robot.

What Is Automation Validation and Why Is It Important?

Automation validation is the process of testing an automation solution to ensure that it meets the required standards and specifications. This is important because automation systems can be complex and expensive. The practice of automation validation is most often used in closely regulated industries.

If you are working in an industry with strict regulations, such as pharmaceutical or aerospace manufacturing, you may be legally required to validate any automation solutions you use. However, even if you operate in another industry, validation can be useful as it allows you to solve any potential problems before the automation is put into production.

Validation allows you to prove that the solution meets your required standards. If you are measuring the solution to meet your company’s own standards – rather than those of a regulator – you first need to define what those standards are.

For example, if you need your robot to run for at least 19 hours a day with no issues, this will be one requirement you may test for.

Why Use Robot Simulation for Automation Validation?

Any automation can be complex, but robots can be particularly complicated to validate because of their multi-layered architectures, ability to interact with their environment, and wide range of accessories. The success of a robot doesn’t just depend on its hardware and software components, but also on how these components work together.

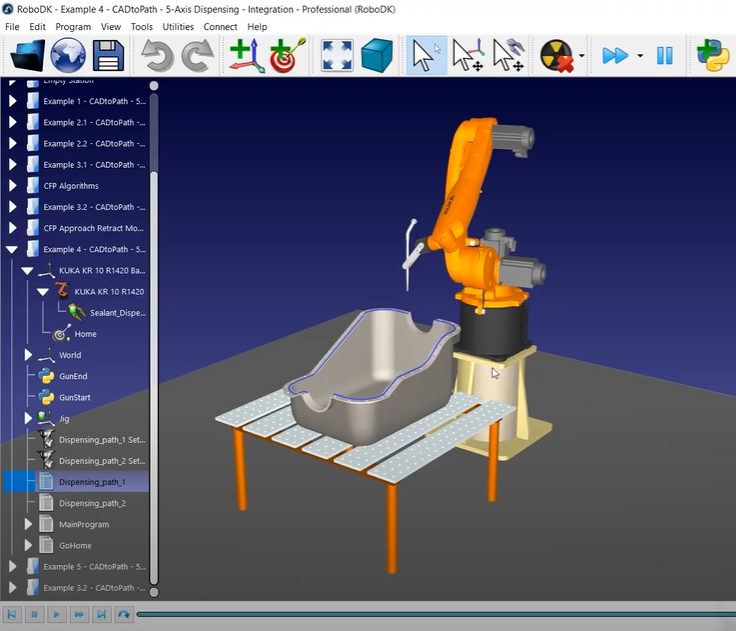

Robot simulators, like RoboDK, provide a virtual environment where you can test your robotic system safely.

With a good robot simulator, you can easily test various aspects of your automation solution. You can quickly run multiple tests on your chosen setup and identify aspects that you still need to improve.

You can then use exactly the same simulation software to make those improvements to the robotic setup. The right robot simulator will help you identify potential problems up front and give you the tools to solve them.

When to Validate and When Not to Validate

How can you tell when you should validate an automation solution design and when you can safely leave out this step?

It’s a good idea to consider automation validation for any automation design, whether it’s a simple automation solution or a more complex system.

There are only ever benefits to thoroughly testing your designs. There are very few downsides. The major drawback of automation validation is usually the time that it takes. However, with a good robot simulator, this time is reduced compared to when you only validate the physical robot setup.

If you are operating in a highly-regulated industry, you should check if automation validation is a legal requirement. Identify which standards and regulations you need to follow and comply with the specified testing procedures.

7 Factors to Test and Optimize Your Automation Strategy

What aspects of your automation setup can you test with a robot simulator?

There are many factors that you can validate within a simulator. Which you choose to test during your validation will depend on your performance requirements for your robotic solution.

Here are 7 examples of factors that you can test with a robot simulator:

- Robot reachability — You can use a simulator to test whether the robot can reach all the required areas of the workspace. By using reachability analysis you can also optimize the robot placement to make best use of its reachability.

- Interaction — When multiple components are interacting, you can validate how well the interaction is working, such as with conveyors.

- Cell layout — By testing different cell layouts, you can validate that you are using the most optimal layout for your particular task.

- Scalability — One significant benefit of robots is their ability to flexibly adapt to changing production requirements. In a simulator, you can analyze your solution to see how well it scales.

- Cycle time — The robot’s cycle time is a key metric to determine its performance. With a simulator, you can measure how long it takes for your robot to complete its tasks and adjust if needed.

- Safety — Safety is a core aspect of many legal automation validation requirements. You can use your simulator to model and analyze the safety performance of the automation system.

- Utilization — Your solution’s utilization has a powerful impact on the return on investment you get from your robot. In the simulator, you can test the robot’s utilization.

By validating your automation designs with robot simulation, you can ensure that your system is efficient, safe, and reliable. In the long run, it will help you save time, money, and resources.

How to Use Robot Simulation to Validate Automation Designs

The first step to using robot simulation for validation is to become familiar with the simulation software. Download a copy of RoboDK and build your first robotic simulation.

Then, identify which performance parameters you want to test for your automation solution. Don’t go overboard — just list a few key parameters and then test them.

Once you have measured the performance of your robotic simulation, make any changes you need so that your robot operates as necessary.

Finally, upload your robot program to your physical robot and run some physical validation before putting it into production. This validation step should be much shorter than without simulation, as you will have ironed out potential problems within the simulator.

What aspects of your robotic solution do you need to validate? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.. Also, check out our extensive video collection and subscribe to the RoboDK YouTube Channel