If you’re in the market for an end effector for robot drilling, it can be hard to know which tool to choose.

Is robot drilling the same as any other type of drilling when it comes to purchasing a tool?

Or are there are extra properties you need to be aware of?

Robot drilling is a relatively simple activity. You just need a bit of basic knowledge to find the right end effector for you.

Drilling Spindle: The Tool of Choice

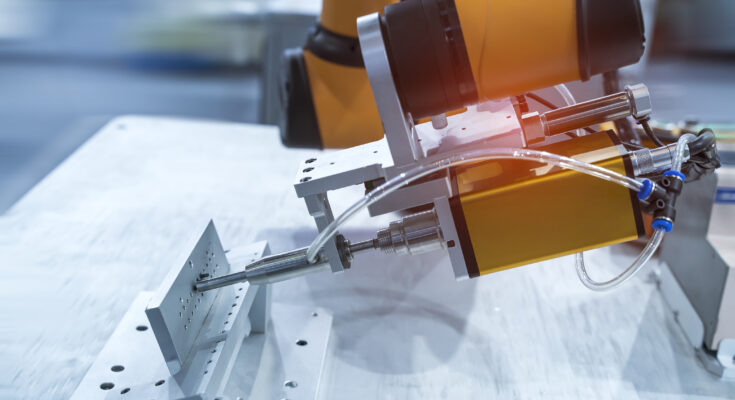

Your options for drilling end effectors are relatively straightforward. If you want to drill with a robot, you likely need a drilling spindle.

A drilling spindle fits directly to the wrist of your robot. It holds the drill bit and provides the necessary torque and speed to drill holes. The robot simply holds the spindle in position on the material.

How a Drilling Spindle Works

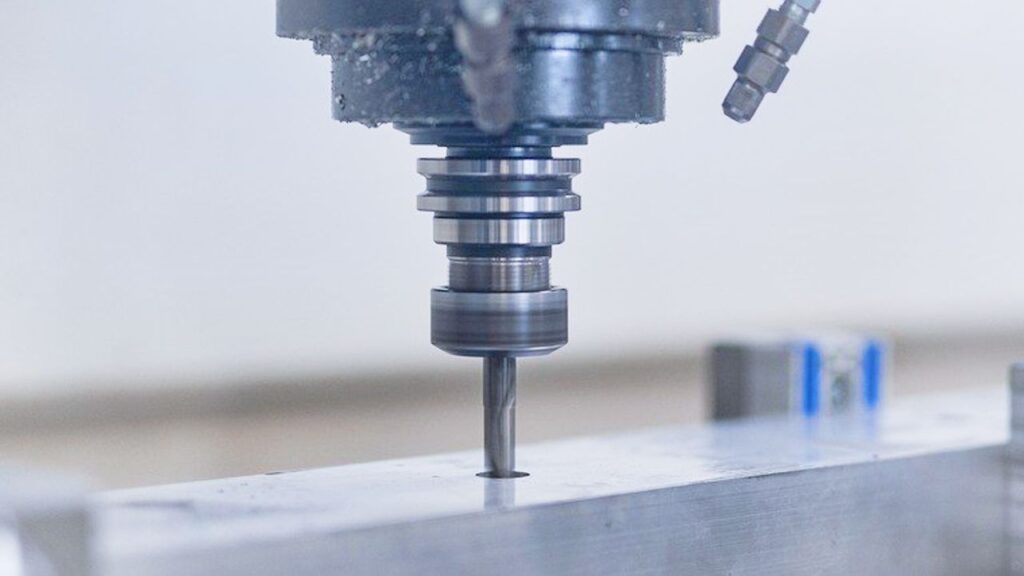

You can think of a drilling spindle as being very like a handheld power drill. Unlike static pillar drills, which have large motors and drive belts to provide high torque, a drilling spindle is compact. Everything is contained within the spindle.

However, this doesn’t mean that the tool is necessarily less powerful than other drilling tools. The TeknoMotor C31/40-C machining spindle, for example, which is included in the RoboDK library has 700W power. This is double the power of many home pillar drills.

Finding the Right Robotic Spindle for Your Task

Which drilling spindle is best?

The answer depends on the needs of your specific task. You will need to assess a few properties when comparing the different robotic spindles available on the market.

Factors that affect your choice of spindle include:

- The robot model you are using.

- The material you are drilling.

- The speed and force required for this drilling task.

There are a few tips you can follow to get the most accurate robotic drilling, such as ensuring that the robot has the required stiffness to complete the drilling task.

Drilling vs Machining Spindles

Another type of robotic spindle you might see is machining spindles. These are very similar to drilling spindles. The main difference is that machining spindles support both axial and radial loads while a drilling spindle will only support axial loads.

If you are thinking of trying robotic machining, it could be worth investing in a machining spindle for both drilling and machining.

7 Properties to Look for in a Robot Drilling End Effector

What features should you prioritize when you are looking for a drilling end effector?

Compared to other robot tools, drilling spindles are reasonably simple. Even so, there are a few properties that you will want to consider when looking for the right spindle for you.

Seven common properties are:

1. Lightweight

A major difference between robotic drilling and other types of CNC drilling is the weight limit.

Robots have a limited payload capacity that influences the amount of force the robot can apply to a surface. If you choose a heavy drilling spindle, this may reduce the amount of force that the robot can apply when drilling, depending on the orientation of the end effector at the time.

2. Cooling

Drilling tools get hot. There are various cooling systems you can use to reduce the heat of the tool when it is operating.

Examples of cooling systems include air convection, air vortex (which uses compressed air to generate supercooled air), liquid, and fans.

3. Mounting Options

You need to be able to fix your drilling spindle to the end of your robot arm.

If there is no mounting option for your robot model, you can likely still use the drilling spindle. You will just need to manufacture your own mounting plate to connect the spindle to the wrist of the robot.

4. Power System

Drilling spindles are often electrically driven. However, there are also pneumatic and hydraulic drilling spindles available on the market.

Bear in mind that you may need to purchase an extra power system for your end effector if you don’t have a suitable one already available.

5. Spinning Speed

The speed of your drilling spindle will influence how quickly it will drill through a particular material and there are a few different formulas used to calculate this.

Spindles come with a wide range of speeds from 0 RPM to 30,000 RPM or more.

6. Power or Force

The power or force of the drilling spindle will influence the type of material that it can be used to drill. For instance, drilling titanium will require a higher power tool than drilling soft aluminum.

The power is usually specified in horsepower or watts.

7. Tooling Options

The “business end” of any machining spindle is the drill bit that you attach to it. You need to ensure that your spindle supports the drill bits that you want to use and vice versa.

Common tooling options include a standard collet (as seen on a pillar drill), pneumatic fitting, and automatic tool changers.

A Useful Tip for Programming Your Robot Drilling Spindle

What do you need to remember when you are programming your drilling robot?

Firstly, it’s a good idea to use a programming interface that is designed for robot machining and drilling. For example, RoboDK comes with a machining wizard that allows you to add machining and drilling paths quickly and easily.

A useful tip for programming is to remember that calibration is vital. When you are drilling manually, you can see the tip of the drill bit. This makes it very easy for you to adjust to changes in the bit position.

With a robot, the only way that you will know that the drill bit is in position is to properly calibrate the robot whenever you change the tool.

Which property is most important for your robot drilling? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.