The landscape of warehouse automation is undergoing a transformation, driven by the rapid advancements in robot palletizing technology. As businesses strive for greater efficiency and agility in their operations, the role of robotics in palletizing is becoming more important. Several trends in robot palletizing are reshaping the industry.

Flexibility and Adaptability

Robotic systems are no longer rigid and limited to specific tasks. Today’s palletizing robots have unprecedented flexibility, adapting to a range of products and packaging types. This adaptability is a game-changer for industries with diverse and evolving product lines, ensuring that automation does not come at the cost of versatility.

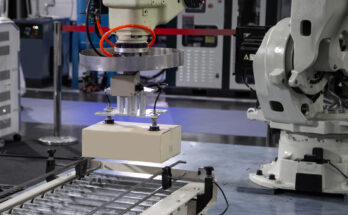

Advanced Vision Systems

The integration of advanced vision systems in palletizing robots is a leap forward in precision and efficiency. These sophisticated systems enable robots to accurately identify, sort, and position items, regardless of their size, shape, or orientation. This technological advancement not only boosts productivity but also significantly reduces the margin of error.

The Rise of Collaborative Robots

Collaborative robots, or cobots, are revolutionizing the palletizing process by working hand-in-hand with human workers. These cobots are not only user-friendly and cost-effective but also enhance safety and efficiency in the workplace. They represent a synergistic approach to automation, where human ingenuity and tireless combine to achieve optimal results.

Connectivity and IoT

In the age of the Internet of Things (IoT), palletizing robots are more connected than ever. This interconnectivity facilitates real-time data analysis, predictive maintenance, and remote operations, turning palletizing systems into integrated parts of a smart warehouse ecosystem

AI and Machine Learning

Artificial Intelligence (AI) and Machine Learning are propelling palletizing robots into a new era of smart automation. By learning from past experiences, these robots are constantly improving, making more informed decisions, and optimizing palletizing tasks. This continuous learning curve paves the way for more intelligent and autonomous robotic solutions.

Sustainability

As the world gravitates towards sustainable practices, robotics in palletizing is not far behind. Emphasizing the efficient use of materials, energy conservation, and waste reduction, these robots are playing a crucial role in promoting sustainable operations in the logistics and supply chain sectors.

Customization and Modular Solutions

The trend towards customized and modular robotic solutions is reshaping the way businesses approach palletizing. This flexibility allows for tailored solutions that fit specific operational needs and makes scaling and modifying systems more straightforward and cost-effective.

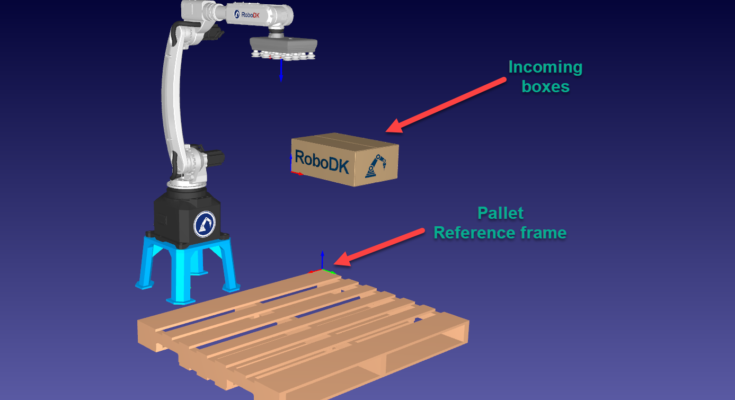

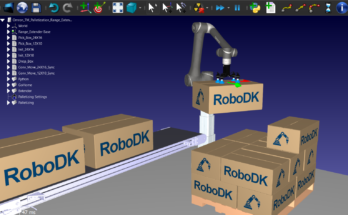

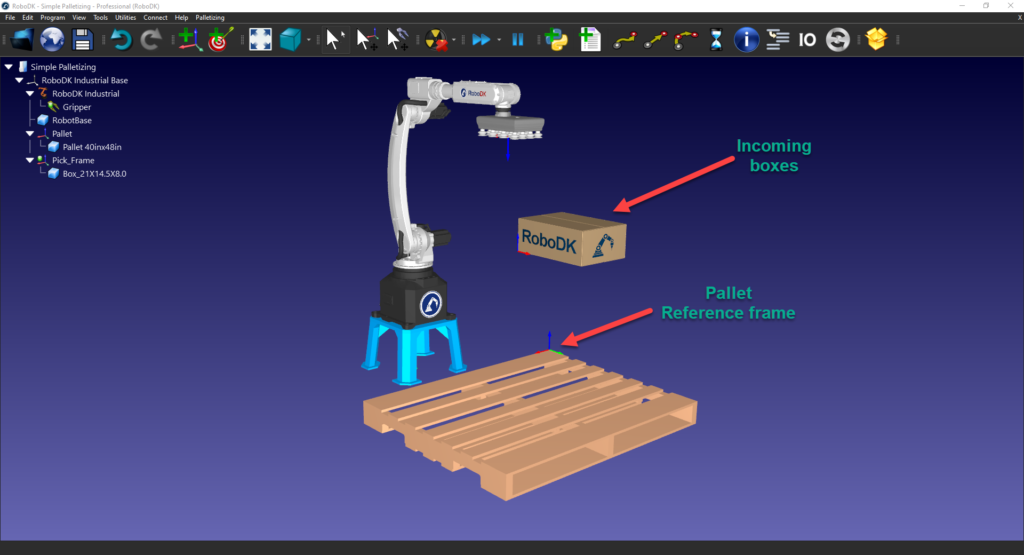

Palletizing with RoboDK

To help with these challenges RoboDK has developed a palletizing plugin specifically designed to simplify the process of programming robots for palletizing tasks. This plugin is compatible with a wide range of robot brands, making it a versatile tool for various robotic automation applications. Moreover, the RoboDK Palletizing plugin has a user-friendly Interface that helps in the quick creation of palletizing programs.

Real-time simulation

The RoboDK plugin utilizes an efficient 2D layout builder, paired with the 3D environnement preview, where users can create pallet patterns by dragging boxes on the screen. It is also able to program the task offline. and allows users to easily drag and drop each box to its desired position on each layer of the pallet. A 3D visualization aids in real-time simulation, enabling users to adapt the settings to suit their specific requirements.

What questions do you have about robot palletizing? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum. Also, check out our extensive video collection and subscribe to the RoboDK YouTube Channel.