When you are looking to automate your production line, choosing the right industrial robot programming software is an important decision. Here’s how to pick the right one…

Whether you are a manufacturer, industrial engineer, or another industrial robot user, the goal is probably the same… make programming as simple, fast, and reliable as possible.

There are various options for programming your industrial robot. Your choice of software can mean the difference between a smooth, efficient deployment and months of frustrating trial and error.

In this article, we’ll explore the best software options for industrial robot programming and help you choose the one that best fits your workflow.

What Is Industrial Robot Programming Software?

Industrial robot programming software is a type of specialized tool for creating, testing, and optimizing the control of industrial robots. Such tools provide a programming environment for controlling robotic motions, with common features including code debugging, simulation, and collision avoidance.

Traditionally, it was only possible to program industrial robots with the tools provided by the manufacturer. These tended to be very limited and usually involved using a teach pendant or simple script-based programming through a computer. If you used a particular robot brand, your options for programming were restricted.

More recently, many options have appeared for robot programming from a range of providers.

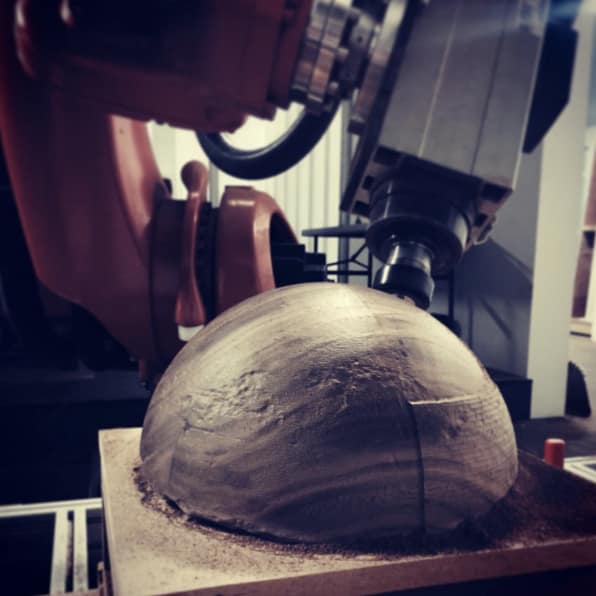

Some software packages are only suitable for particular industrial processes, like painting, packaging, or assembly. Others provide a common programming environment for a diverse range of applications.

Why Offline Programming Is the Smart Choice for Industry

A common question when choosing between programming solutions is, “Do you want to program the robot online or offline?”

In reality, there is very little reason these days to program your robot online. However, this is what the two terms mean:

- Online Programming — This approach involves stopping production to program the robot. This could mean teach pendant programming or hand-guiding which is common with collaborative robots. A major issue with this approach is that it involves halting production, so programming or debugging the robot will always be costly.

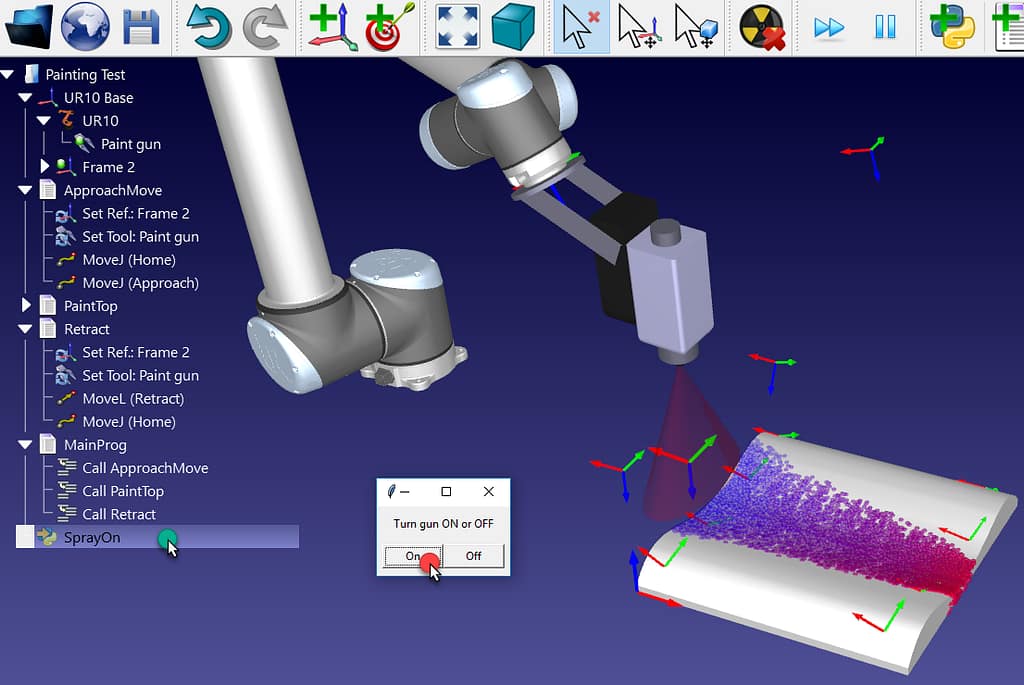

- Offline Programming — With offline programming software, you can program your robot in a virtual environment with no need for the physical robot to be present. This allows you to test, debug, and optimize your robot program without affecting production.

Which option should you choose? The answer these days is clear.

While online programming was popular in the past, there are few production environments where it makes sense these days.

Apart from hands-on programming of collaborative robots — which is most often done by new robot users — most industrial tasks will benefit from simulation and offline programming.

Comparing the 3 Top Types of Industrial Robot Programming Software

What options are there for industrial robot programming software?

While there are various names you might see popping up, there are only a few key types of programming software.

Here are the 3 main types of industrial robot programming software you might find:

1. RoboDK

RoboDK is one of the most comprehensive and popular robot programming software tools available. With a focus on vendor-agnostic programming, it is compatible with dozens of leading robot brands and over 1200 robot models natively.

With tools for specific applications like robot machining, robotic welding, inspection, assembly, and more, RoboDK provides an easy-to-use and powerful programming environment. It is accessible both to new robot users, through its graphical interface, and advanced users and functionality through the RoboDK API.

2. Robot Brand Tools (e.g. RobotStudio, Roboguide)

Most of the bigger robot manufacturers provide their own proprietary programming software. Examples include ABB RobotStudio and FANUC Roboguide.

These software solutions come with a range of features that vary among them. They may include simulators, with varying degrees of functionality, and coding support for the manufacturer’s proprietary programming language.

The major difficulty of these solutions is that they create “lock-in” to that particular manufacturer. This can be acceptable if you know for sure that you will only ever purchase robots from this brand over the lifetime of your business. However, this choice can be restrictive.

3. Other Third-Party Software

Other software tools exist for robot programming from third-party providers. These vary hugely in functionality and support for robot brands.

As with any software purchase, the more options you have, the more complex the decision.

To make your choice easier, we have included a set of questions below that you can ask yourself when comparing tools.

5 Questions to Ask Yourself When Choosing an Industrial Robot Programming Software

When choosing between robot programming software for industrial automation, it helps to ask the right questions.

As you look at the options, ask yourself:

- Does it support multiple robot brands? Choosing software tied to one manufacturer limits flexibility. Unless you are very sure you’ll never use another robot brand, pick a solution that reliably supports a lot of robots.

- Can it simulate before deployment? In most cases, offline programming is the sensible option. Simulation prevents costly downtime. Pick a software that lets you test toolpaths, detect collisions, and refine accuracy before running the robot.

- Is it compatible with your design tools? Your robot programming software is only one part of your entire software workflow. Make sure you pick a solution that means you don’t have to change everything about your software workflow.

- Does it have an API to support advanced applications? If you plan to automate complex or custom processes in future, check whether the software includes an API. This allows integration with external systems, sensors, and AI logic. A robust API makes it possible to adapt and extend your automation over time.

- Will it scale with your automation goals? As your automation grows, so should your software. Look for a platform that supports both small, single-robot setups and full-scale multi-robot systems.

With questions like these, you can ensure you find a robot programming software that meets your needs.

Final Thoughts: Finding the Right Software for You

Ultimately, there isn’t a single “best” robot programming software for everyone. There is only one that fits your setup, experience, and goals.

If you already use one brand of robot and you want to keep things simple, it might make sense to keep using your existing manufacturer-specific tool. However, as you are reading this post, it is likely you are looking for a change.

If you’re looking for flexibility, or plan to expand your automation over time, a more open and universal solution will save you headaches later.

The important thing is to choose a tool that lets you program confidently, experiment freely, and keep your production moving. The best robot programming software is the one that helps you get actual work done efficiently and reliably.

Which robot programming tools have you tried? Join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.. Also, check out our extensive video collection and subscribe to the RoboDK YouTube Channel