Virtual reality looks set to transform the way we interact with our computers. But, it’s already changing industries. Here are 10 exciting applications.

The world of offline programming has just entered the age of virtual reality, thanks to our recent software update. With the new VR functionality, you can now immerse yourself in the virtual world of your robot workstation.

Although VR is new to offline programming, it already exists in some industrial applications. Some of these applications are already changing industries and others are set to become big in the near future.

Here are 10 industrial tasks that will be transformed by the newest wave of virtual reality technology.

1. Enhanced Virtual Meetings

You could say that communication has been the main driver for many of the modern technologies that we now take for granted. Video conferencing, social media, customer service messaging, they all help us to communicate more effectively with our fellow humans over the internet.

It makes sense that virtual reality meetings are the next step. Many companies are actively trying to find ways to reduce their carbon emissions and reducing international travel is certainly one way to do this. VR meetings allow for an enhanced meeting environment compared to other video conferencing options.

2. Low-Cost Workplace Training

Training is one of the most exciting industrial applications for VR, especially for dangerous or costly-to-train jobs. The virtual environment allows you to train your workers in a very realistic environment much more cheaply than, for example, creating a physical mock-up of the work location.

Of course, one type of virtual reality has been used in the aerospace industry for years. Pilot-training has long been done with flight simulators, which are essentially advanced VR systems. However, any business can use VR for training. Walmart has recently deployed VR units to 5000 of its stores to train its managers.

3. Next-Level Customer Engagement

Are you a robot integrator? Do you design products which benefit from a “test drive” before purchase? What could you achieve if your customers could try out your product before you had even built it?

Virtual reality has a real potential to improve customer engagement by letting them interact with a virtual model of your product. For custom products, this could turn out to be a game-changer. For example, as a robot integrator, it’s much more cost-effective to change the RoboDK model of your solution than it is to build and program the physical robot… only for the client to then request changes.

IKEA has already started using VR to allow customers to “try out” their kitchen design.

4. Immersive Engineering Design

The virtual environment doesn’t only help the customers to engage better with your design. It can also help you as the designer to better understand your own design.

Virtual reality engineering has actually been around for some time. Jaguar Land Rover, for example, was using it as far back as 2006. VR allows us as engineers to get detailed feedback about the strengths and weaknesses of our designs before the costly phase of building physical mock-ups. Of course, VR will never replace physical mock-ups completely but it can improve the efficiency of the entire engineering process.

5. Remote Equipment Diagnostics

One interesting industrial application involves improving remote diagnostics and maintenance tasks with VR. One way is to use it in collaboration with Augmented Reality — where virtual objects are overlayed in real-time over a video image of the real environment. In this way, an expert maintenance engineer can remotely guide a non-expert worker to perform diagnostic and maintenance tasks.

6. Robot Selection

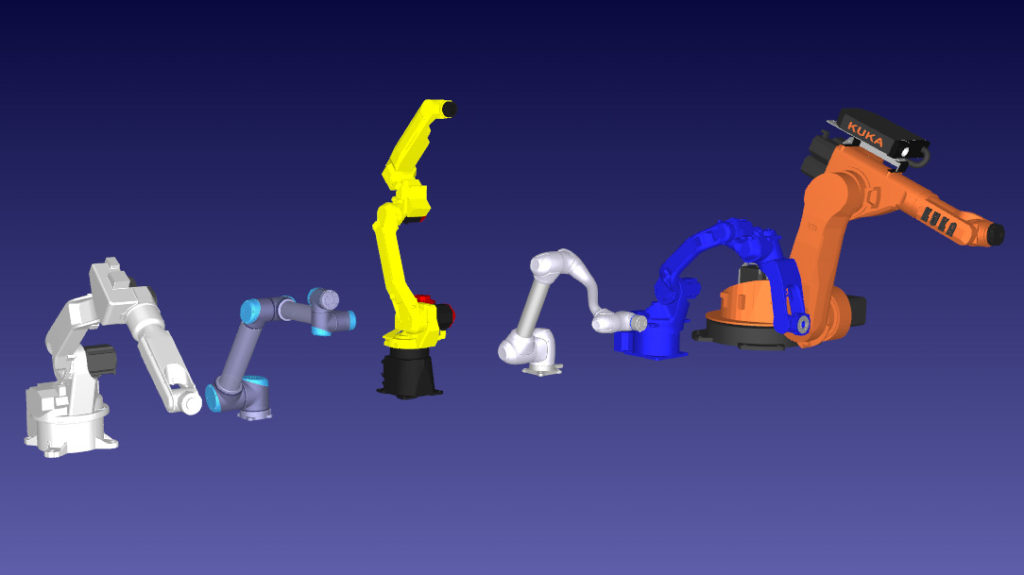

We have already mentioned how VR can help your customers to “test drive” your products in a virtual environment. The same benefit applies to you as a customer. For example, when you are trying to decide which model of robot you want to purchase, VR can provide a great way to do that.

We often talk about the fact that RoboDK can be used to try out different robot models with your application before you purchase the robot. Imagine how much better you could test the robot by experiencing it in an immersive virtual environment!

7. Immersive Events and Conferences

A rising trend in conferences is to provide an alternative, online experience for those people who cannot attend in person. Until now, these virtual alternatives have been a less-than-wonderful experience. But, virtual reality conferences look to change all that.

As one journalist attending a VR conference explained, the experience is still not perfect but it is certainly more immersive and looks set to be part of the future of conferences, trade fairs, and other industry events.

8. Debuggable Assembly Steps

Many products require some assembly steps in their manufacture. Traditionally, the only good way to “debug” this process was to make a physical prototype of the product and try out the assembly steps yourself. Of course, this will always remain part of the design process for physical products.

Virtual reality adds an additional, valuable test stage by allowing engineers to test the assembly steps in a virtual environment. This is more realistic than just testing the assembly in your CAD package and lets you deal with potential assembly problems before they arise.

9. Construction Design

The advantages that we mentioned above with respect to engineering design are also applicable to the construction industry. We have talked about construction robots a few times here on the blog (mostly with regard to robotic 3D printed architecture).

VR is already starting to change the construction industry by allowing architects to “walk through” the construction site and experience their design before a single drop of concrete has been poured.

10. Programming Robots

Many of the examples listed above can already be found in use in some industries. But, the industrial application that we are most excited about here at RoboDK is using VR to program your robot.

You can try it out for yourself by downloading the latest version of the software, which includes VR support for the very first time.

What industrial application do you think could benefit from VR? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram or in the RoboDK Forum.