Pharmaceutical companies are adopting robots faster than in any other industry at the moment.

But, what robot applications should you deploy in your company?

Which of your tasks are suitable to give to a robot?

The pharmaceutical industry has experienced a lot of changes recently. The world has been moving quickly and companies have had to adapt their processes to keep up.

Robots are one of the prime technologies that pharmaceutical companies are using to keep ahead of the curve. According to a recent report, the growth of robotics in the pharmaceutical industry is currently higher than in other industries.

You might be looking at this trend and thinking “Should my company add more robots to our operations?”

Maybe you have used robots before or maybe this is the first time you are thinking about using them. Either way, it can be difficult to know which application you should choose to get the most out of your investment.

Are Robots Really Relevant to My Business?

If you search for advice about robotics in the pharmaceutical industry, useful information is rather thin on the ground compared to some other industries. Most of the good blogs — ours included — speak to manufacturers more often than we do to pharmaceutical companies specifically.

This might lead you to wrongly assume that robots are less used in the pharmaceutical industry.

You might look at suggested applications such as robot machining, painting, and welding, and think… are these really relevant to my business?

However, many great robot applications can be beneficial to the day-to-day needs of a company like yours.

Even though there might be less information out there, your competitors are probably already using robots. According to a recent article from the PharmaTimes, there is a growing reliance on robotics and automation within the industry, particularly since 2020.

How to Identify the Right Application for a Pharmaceutical Company

The key to finding a good robot application for you is to focus on those that will give you a quick win.

Think about the benefits that the robot will bring that are most important to you and your business.

Common impacts of robotics on pharmaceutical companies include:

- Increased productivity — Robots can improve the production output of a particular task.

- Better consistency — A robot will always complete the task in exactly the same way every time, which improves product consistency.

- Reduction in downtime — A robot can run 24 hours a day, if necessary, and does not need to take breaks.

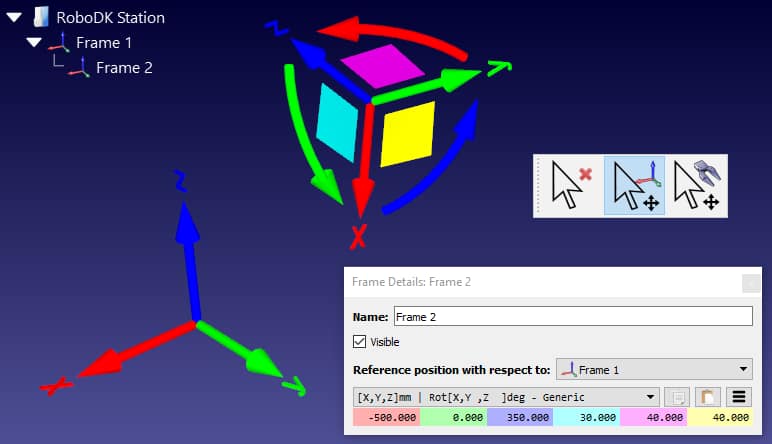

- Increased flexibility — With the right programming tools, you can quickly change the robot’s task to respond to changes.

- Faster time to market — Robots are helping many pharmaceutical companies to “plan for the unknown” by giving them more responsive R&D.

Think about which of these benefits will be most impactful for you and your business.

Which tasks, in particular, would most benefit from these effects? These are good signs that a task might be a good candidate to give to a robot.

It is also helpful to think about which tasks will allow you to get a quicker return on investment with the least amount of upheaval. These are good candidates for your first robot deployments. After you have had some success with your first robot applications, you can move onto other tasks.

6 Robot Applications for Pharmaceutical Companies

Many robots could be right for pharmaceutical companies.

Here are 6 potential applications that work well in pharmaceutical companies:

1. Pick and Place

As the name suggests, pick and place involves moving objects from one space to another. This could mean moving items from a conveyor into a work area, sorting items for further processing, or any similar task.

Examples of pick and place tasks include sorting bottles of medicaments, arranging syringes for packaging, and removing defective products during inspection.

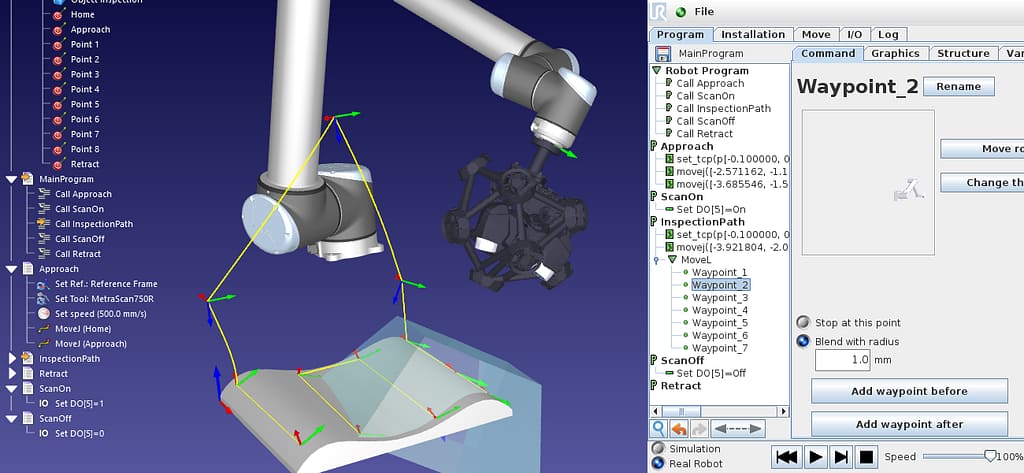

2. Inspection

Inspection is an arduous task in any industry and the ramifications of inconsistent inspection could be catastrophic for a pharmaceutical company. Robots are a great way to improve the consistency of inspection tasks.

An example of an inspection task might include checking that all compartments in a blister pack are filled.

3. Capping Bottles

A common task in some pharmaceutical companies, capping bottles is a tried and tested robotic application. With the right robot, end effector, and sensors, capping bottles with a robot can make for a faster, more consistent process.

An example of a bottle capping task might be to place caps on medication bottles.

4. Dispensing

Dispensing is a task that people don’t always consider for a robot. However, robotic dispensing is used in various situations from gluing to food production. Either the dispensing tool is fixed to the robot or the robot moves containers under a dispensing machine.

An example of a dispensing task might be to fill syringes with medication.

5. Machine tending

There are plenty of semi-autonomous machines in the pharmaceutical industry. Usually, these are loaded and unloaded by a human operator. However, this is not the best use of the person’s time. A robot is a much better option for machine tending tasks, allowing the operators to carry out more value-added tasks.

An example of a machine tending task might be to feed samples into a testing machine.

6. Packaging

Every product that leaves your business needs to be packaged. There are usually multiple opportunities to hand off packaging tasks to robots within a pharmaceutical company.

Examples of packaging tasks include packing products into individual bags, loading products onto trays, and stacking boxes onto pallets.

How to get your robot up and running quickly

As you can see, there are various options for robot applications that you could introduce into your business. In addition, there are even more options aside from the ones listed in this article.

If you are looking to get started with a robot deployment, one of the most important decisions you will make is what programming tool you will use.

The right programming tool will make your life easy while the wrong tool could add weeks to your robot deployment.

Click here to learn about a programming tool that can get your robot up and running quickly.

What task sounds good to you? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.