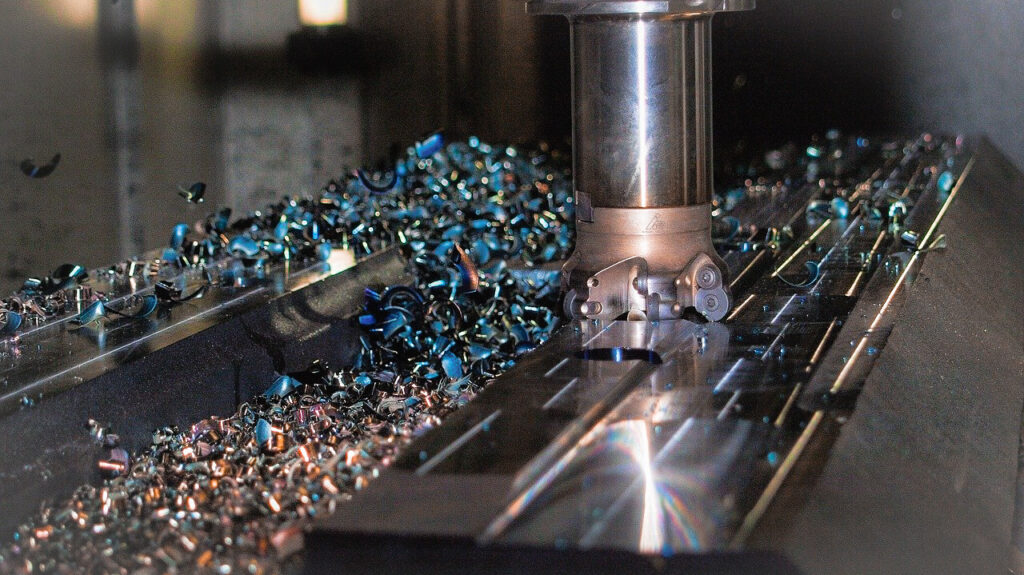

For years, machining hard metals has been a significant challenge for manufacturing automation. With new robot machining systems, machining hard materials is now possible.

Hardened steel, tempered steel, titanium, and other high-strength materials are essential in industries like aerospace, automotive, and energy.

However, the very strength that makes these materials valuable also presents a problem for automation. Traditionally, they could only be handled by specialist, rigid CNC machines — a machining robot would have no chance!

But, this is changing…

In this article, we’ll explore how new high-stiffness robots are redefining what is possible with robotic machining. We’ll cover what makes certain materials difficult to cut and how robots are now meeting the challenge.

From Easy to Extreme: Why Hard Metals Challenge Some Machining Systems

The first step to truly understanding the potential of robotic machining is to understand the materials themselves.

Machinability is a measure of how easily a material can be cut. It depends on a balance of properties including hardness, ductility, toughness, and thermal conductivity.

Some materials are famously easy to work with, such as aluminum. Others are so hard, heat-resistant, or abrasive that even a small project can wear through tooling or destabilize a machining setup.

Easy to Machine Metals

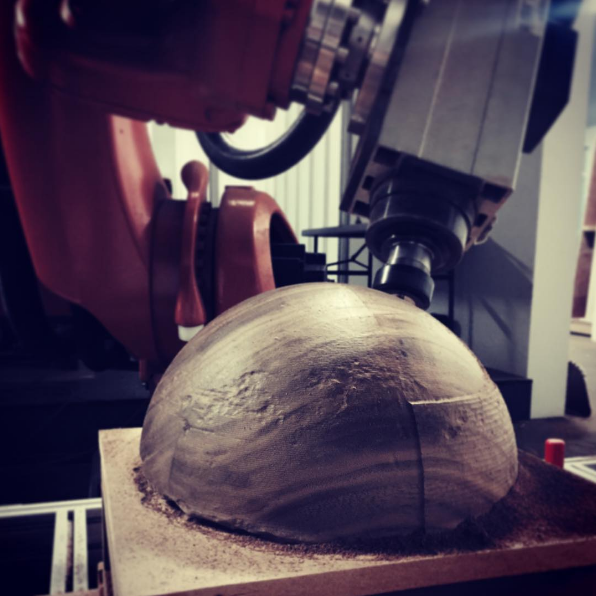

In the past, robotic machining was only robust for soft, easy-to-machine materials due to the compliance of industrial robot joints.

Examples of “friendly” metals that are easy to machine include:

- Aluminum — This stalwart of manufacturing is well known for its excellent thermal conductivity and ease of cutting.

- Mild steel — This is strong enough for structure, but still manageable for machining.

- Brass Used in fewer projects than the previous two, this offers predictable chip formation and minimal tool wear.

Hard to Machine Metals

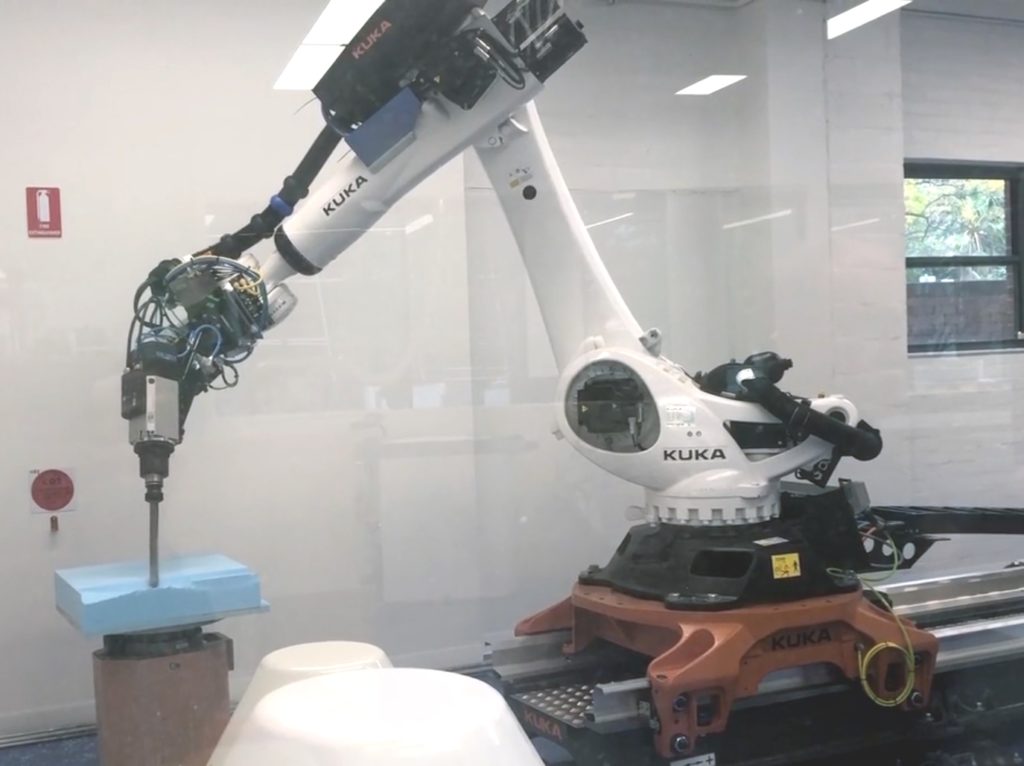

Newer robotic machining systems — such as those from Autonox that we saw at Automatica 2025 — are now capable of machining harder materials that were previously impossible.

Examples of hard to machine metals include:

- Hardened and tempered steel — These steels are treated to resist deformation, putting more strain on cutting tools and thus requiring stiffer machining tools.

- Titanium alloys — These are prized for their strength-to-weight ratio but notorious for poor heat dissipation.

- Inconel and nickel-based superalloys — These specialist and sometimes proprietary materials can retain their hardness even at red-hot temperatures.

While robotic machining is still limited with these materials, the new systems from Autonox that can machine tempered steel, mark a change. Robotic machining is now a viable option for machining hard metals.

The Expanding Role of Robots in Industrial Machining

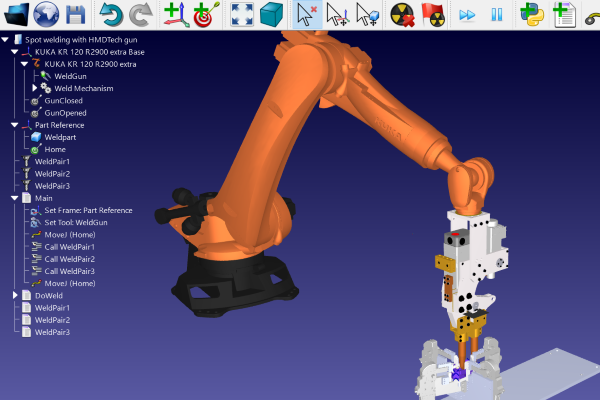

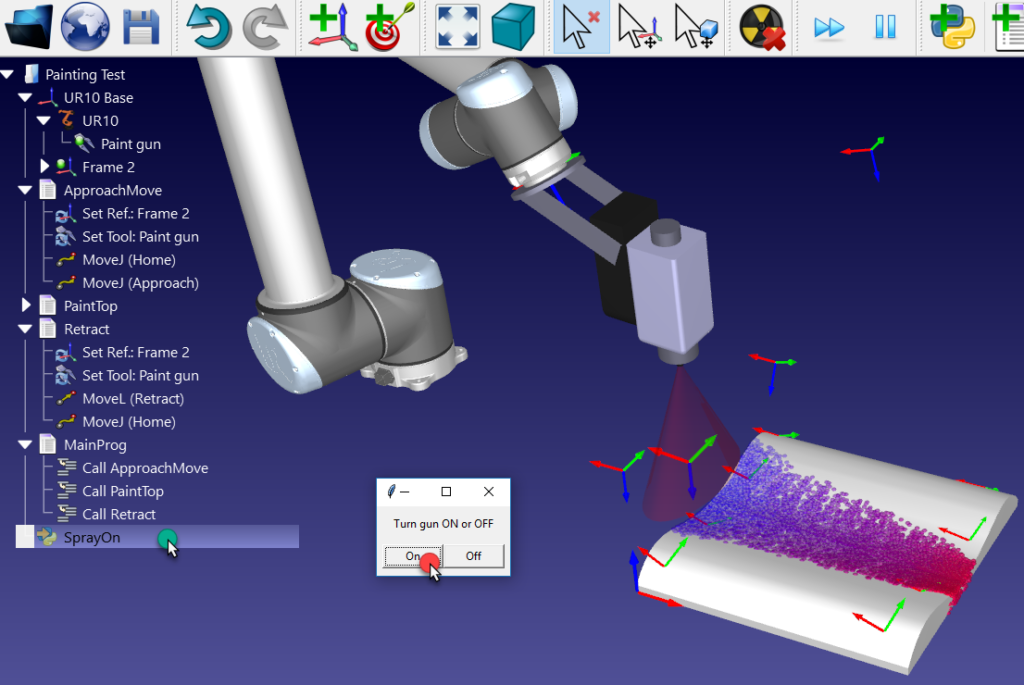

At RoboDK, we have been following the development of robotic machining for years. Our leading robot programming software is used by many manufacturers looking to make their processes more flexible with robotics, including for machining applications.

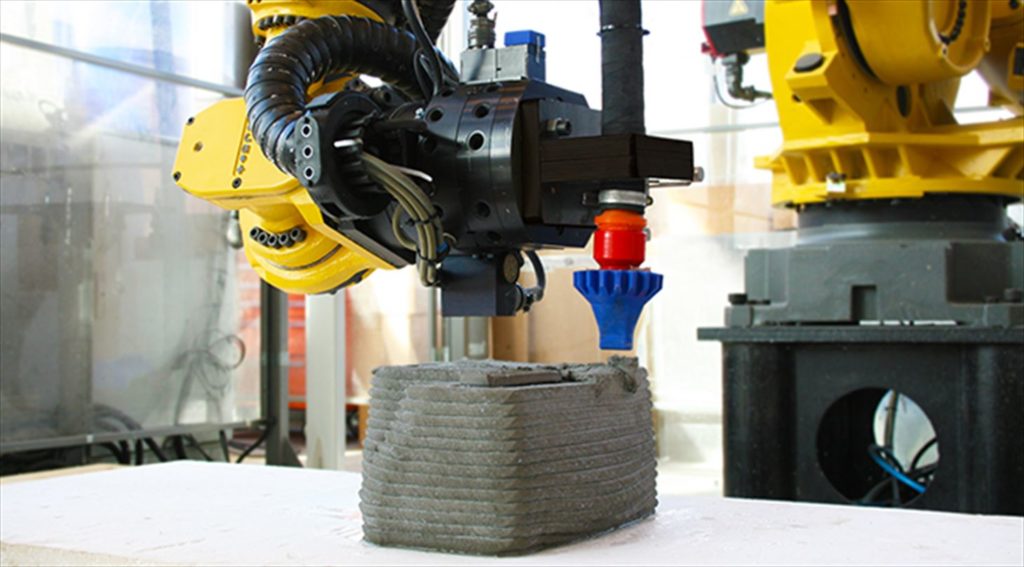

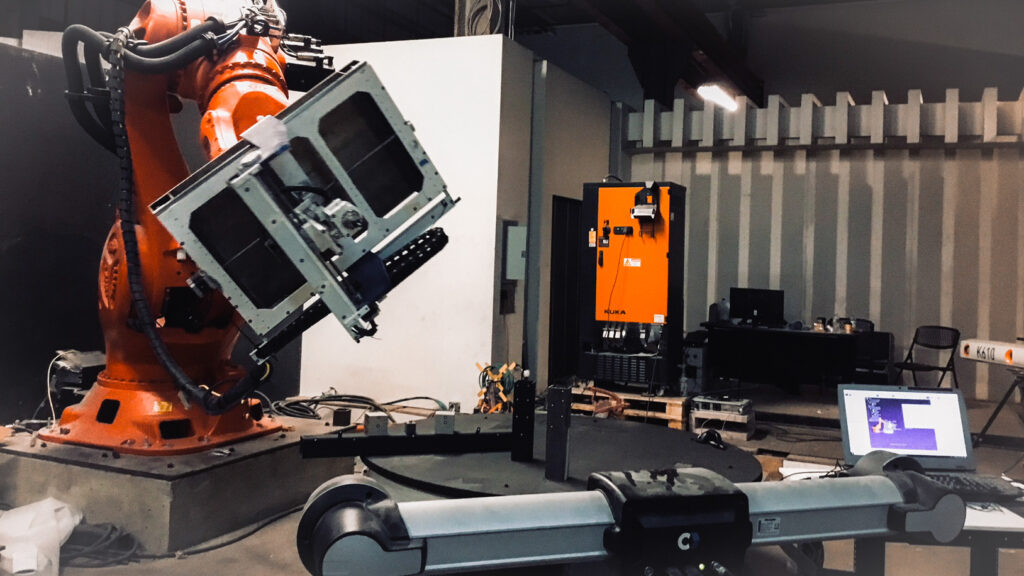

Robots offer additional benefits for machining, including support for larger workspaces, more complex geometries, and greater flexibility for production flow changes.

In recent years, a new generation of high-stiffness industrial robots has created a shift in industrial machining. Operations that previously would only have been possible with a conventional CNC machine are now achievable with robots.

Several factors are driving this development including:

- Improved mechanical stiffness of robotic manipulators.

- Dynamic compensation of vibrations in robot controllers and control software.

- Precision calibration of robotic manipulators.

- High-precision encoders that allow for more accurate joint control and stable cutting paths.

- Robot programming tools for robotic machining like our [set of free add-ons for optimizing applications][ADDON] like robotic machining.

This combination of factors allows robots to handle harder materials with greater accuracy and control than ever before. While still less rigid than conventional CNC machines, the gap between the technologies is reducing.

The Problem: Managing the Forces Behind Hard-Material Machining

The major challenge when machining hard materials is managing the intense forces on the machining tool.

In simple terms, as the robot’s machining tool pushes down on the material, the material pushes back with an equal force. Even a small amount of compliance in the robot mechanism can cause vibrations, leading to machining inaccuracies.

There are two strategies for managing these vibrations:

- Passive: Robot Mechanism Design — The new wave of industrial robots is being designed with high-stiffness mechanical structures that can withstand high forces.

- Active: Control and Programming — Both low-level joint control and high-level programming combine to actively counteract vibrations when they occur.

A robotic system suitable for machining hard materials will combine both strategies to ensure accurate machining.

Robot Calibration: The Secret Weapon in Machining Hard Metals

What steps can you take to improve the accuracy of your robot machining system?

One factor that people regularly overlook is calibration.

When programming a robot to machine hard metals, even the smallest inaccuracy in a robot’s kinematic model can translate into visible surface errors. This is where robot calibration becomes the secret weapon.

Calibration involves identifying and correcting geometric deviations between the robot’s digital model and its real-world behavior. By aligning these parameters, you ensure the tool follows the intended path with maximum precision — a crucial step when tolerances are tight and materials are unforgiving.

We offer a range of Robot Calibration solutions to help ensure your robots perform at their absolute best.

Robot Machining: Redefining What’s Possible With Hard Materials

The ability to machine hardened metals with robots marks a defining moment in industrial automation. What was once considered the domain of only the most rigid CNC machines is now increasingly possible with robots.

By combining the latest wave of high-stiffness robotic mechanisms with the right programming tools, robot calibration, and advanced simulation, you can benefit from the flexibility and scalability that robotic systems offer.

Which challenging materials would you like to machine with a robot? Join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.. Also, check out our extensive video collection and subscribe to the RoboDK YouTube Channel