Do you need to pivot your manufacturing operations?

Maybe you’re considering pivoting but you’re not sure how to get started.

Is it even a good idea for you to pivot?

At some point, almost every manufacturer will consider if they need to pivot their operations. Usually, the pivot is small — e.g. changing from one product line to another. Sometimes, the pivot is huge.

At the time of writing, many manufacturers are looking for ways to pivot their entire operations to produce products to help combat the COVID-19 health crisis. Everyone is looking for ways to stay productive amid the chaos.

The current situation is unusual. But, you don’t need to be in a global crisis to need to pivot your operations.

It could happen at any moment.

Anything could change the landscape of your business. Market forces, supply chain disruptions, strategic changes in the company, technological advancements, … the list goes on. Something changes and suddenly you need to adapt.

What’s the best way to pivot your operations?

Is Now the Time to Jump Into Action?

Once you have identified that you need to pivot a manufacturing line, you might be keen to jump immediately into action.

You probably want to make the changes as soon as possible. After all, every day that you are not manufacturing under your new strategy means wasted time and money.

But, you’ve got to ask yourself: Is it really the time to jump into action?

In some cases, the answer is a resounding “Yes!” It is imperative that you move quickly or you will probably miss the new opportunity that presents itself to you.

In other cases, you can afford to take a bit more time to consider the pivot carefully. You have the opportunity to lay the right groundwork before you change everything.

In both cases, you need to be smart about how you pivot your manufacturing.

The Need to Be Smart When Pivoting Manufacturing

Many situations could be solved by pivoting your manufacturing, either in a small or a large way. But, just because there is an opportunity to pivot, doesn’t mean it’s always the right move to make.

We need to consider the change carefully.

One thing that recessions and global crises have taught us is that a pivot needs to remain “on brand” (as we say in marketing). It needs to be consistent with the company strategy. When companies rush to change their operations just to stay relevant — as is happening at the time I’m writing this article — there is a danger that the company will “go way too far out of their lane” and endanger their long-term success.

If the pivot makes sense for the wider goals of the company, go for it!

One way to be smart about your pivot is to look into flexible automation. Robots are a highly-effective tool for changing your operations in a way that can be easily reconfigured for future changes.

7 Tips for Pivoting Your Manufacturing Quickly With Robots

If you have decided that a pivot is the right option for you, here are 7 tips for implementing your changes quickly and effectively with robots:

1. Focus All Your Efforts on the Pivot

A pivot (particularly a big one) will require a very focused effort, probably from a whole team. It’s important to focus as many of your efforts as possible on the pivot.

As VP of Alexanderwerk Inc, Ralf Weiser, described about their recent manufacturing pivot: “We had to hunker down with our team leadership and pull our emergency deployment and business continuity programs.”

2. Enlist the Enthusiasm of Your Team

Although your decision to pivot is likely have come from the executive team, it is your team that will determine how successful it will be. When pivots are carried out correctly, they can be a time of great enthusiasm and innovation.

As Weiser also recounted: “It is fascinating every day when our team comes up with creative ideas of ‘How can we leverage all this technology that we have that we haven’t really used or had to use?”

3. Look at Technology You’ve Not Fully Explored Yet

Periods of change are the perfect time to explore new technologies and also get more from the technologies you already use.

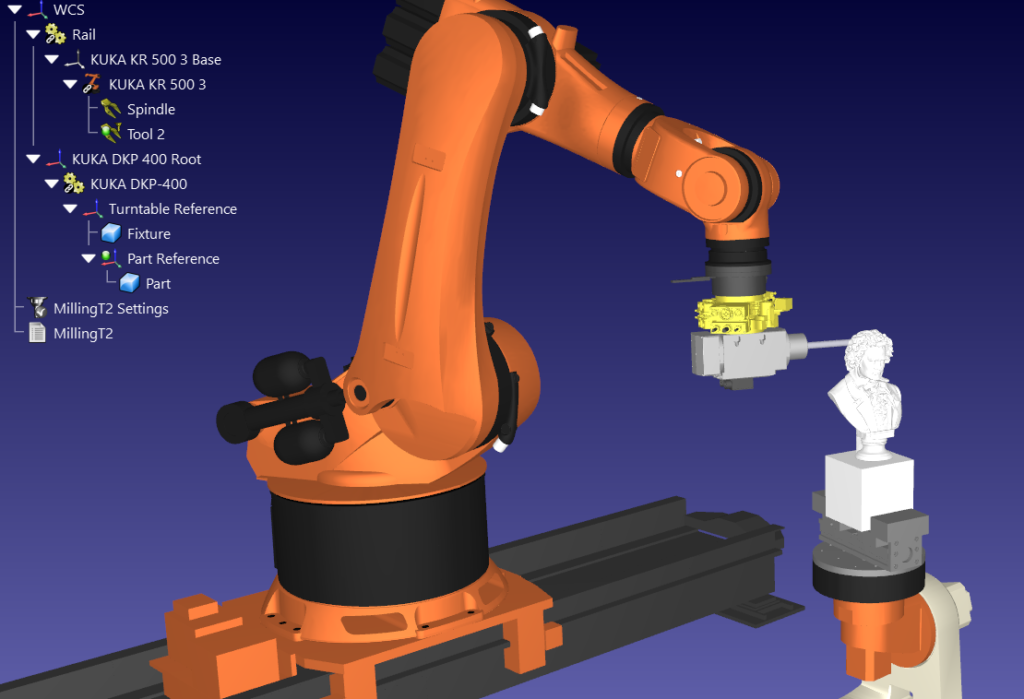

Robots are a perfect example of a technology that can be a great benefit in a pivot. They are flexible, easy to reconfigure, and can be easy to reprogram if you’re using the right software.

4. Leverage Your Existing Expertise and Suppliers

One of the keys to a successful manufacturing pivot is to make the most of the resources that you have already. This means both leveraging the expertise that you have within your business and reaching out to your suppliers for help in making your pivot move smoothly.

As VP of Global Supply Chain, Dave Wheeler, explained about their recent pivot: “We are really fortunate to be able to leverage our current supplier relationships and they all stepped up.”

5. Consider Local Production

Onshoring (i.e. moving operations “back home”) is a growing trend in manufacturing and one that robotics can help immensely. Local production can also be a great benefit in a pivot.

Wheeler also explained: “We wouldn’t have been able to start from scratch and go into production within a week without U.S. manufacturing and all the expertise that comes along with it.”

6. Communicate, Collaborate, and Adapt

As a recent article in IndustryWeek explained, the ability to “communicate, collaborate, and adapt across a supply chain” is the key to pivoting successfully.

Manufacturing processes are complex and can be difficult to change quickly. By responding quickly and ensuring that communication runs smoothly, you ensure that the pivot runs as smoothly as possible.

7. Model and Prototype Rapidly with Robot Simulation

You can speed up the integration of your robotic cell — and improve its quality — by starting out with a virtual simulation of the cell. This allows you to smooth out any kinks in the cell design and programming before you take the leap to integrate it on the production line.

With the right robot programming software, you can also program your robot directly from the simulator without making any changes to your program, making the whole process even more efficient.

When you’re smart about your pivot, it can be the best way to make the most of the current opportunities for your business.

Have you been considering a manufacturing pivot recently? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.