There is one factor that always remains constant in industry, and that is technological innovation. The manufacturing industry is always pursuing innovations to improve production processes and material handling to reduce waste. The case of robotic integration in MRO (Maintenance Repair and Operations) use cases is a good example of using innovation to improve productivity and cost-effectiveness in business.

Robot arms are capable of anything, limited only by their programming, and will perform mundane and complex tasks, like picking, packing, and inspecting, with greater accuracy and efficiency than any human employee. Additive manufacturing isn’t alone in this; many industries, including aviation and healthcare, are taking advantage of robotic integrations and simulation software for prototyping or to prove their ideas have merit.

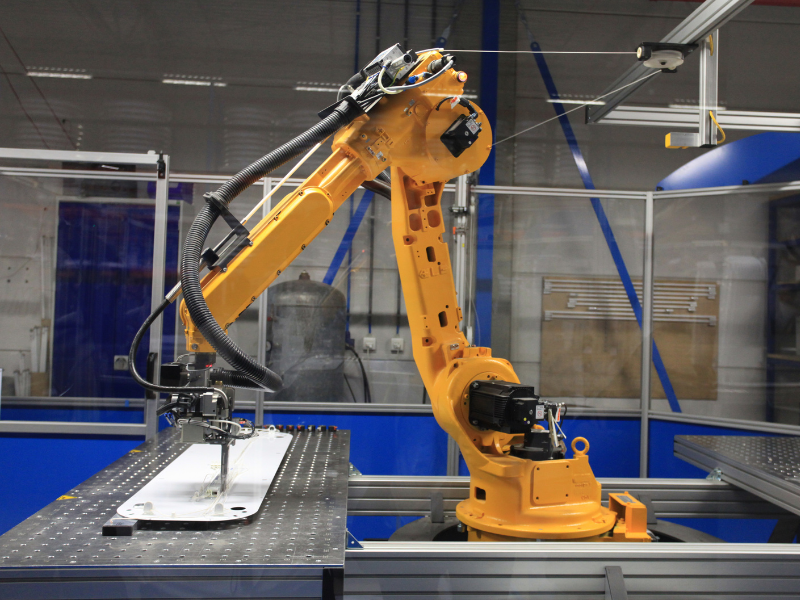

You can find programmable robotics in additive manufacturing because they can reduce the environmental impact of production by limiting energy consumption and waste materials. Companies can install robots onto their production floors using RoboDK simulation software and offline programming tools to make them sustainable. These specific innovations make it possible for any business to monitor and adjust their robots from any location, allowing for greater flexibility in additive manufacturing.

By remaining open-minded to the possibilities of robot integrations, manufacturers will discover how they can improve their MRO applications and, by extension, alleviate any sustainability concerns from their industry stakeholders.

Benefits of Industrial Robotics in MRO Applications

Robots are increasingly valuable for MRO applications because they can consistently perform important and complex tasks. Robotic integration can improve a company’s overall productivity because its innovative features tackle inefficient processes throughout production. Integrating robots improve maintenance activities and leads to better safety standards for company employees.

That’s not all, as using robots in additive manufacturing will decrease the environmental impact of production issues as it reduces waste materials and excess energy consumption.

Integrating robots, using RoboDK’s digital twin and simulation, demonstrates the capacity for software automation to increase manufacturing efficiency. The improvements in manufacturing efficiency are possible because automation streamlines processes and removes the need for labor-intensive steps. Essentially, companies are utilizing RoboDK and similar software to employ digital twin technology in their post-processing steps.

In simulations, companies can monitor their product’s performance for a particular use case, grade the performance by simulating use, and catch any oddities as they happen. In other words, companies can design and program virtual prototypes to gauge their product readiness.

Overall industrial robotics help reduce costs in vital areas while improving accuracy and consistency across industry operations.

Challenges Faced When Integrating an Industrial Robot into MRO Applications

Pairing robotics with existing production processes isn’t anything new, but it can still be challenging due to the complexity of each task. Although, they can simplify the job’s complexity using simple programming techniques for each task. To accomplish this task, manufacturers need to hire experienced engineers who understand the fundamentals of robotics and have the capacity to program them accordingly.

As we mentioned, improving MRO applications with robotic integration and simulation software isn’t impossible, but it does require creative thinking from engineers. Improving MRO use cases will require meeting and addressing the challenges of successful integration.

Integration with Existing Systems

Designing a system that works seamlessly with existing equipment can be challenging. Industrial robots became more common in more industries as more innovation occurred. Because of the need for constant business improvement and success, robotic equipment is integrated with:

- Warehouse control systems

- Material handling systems

- And other automated processes

Manufacturing companies can’t afford production delays. With skillful programming, robots comingle and communicate important instructions to existing systems. Having compatible robotic integrations also reduces process errors and helps complete the job without delays.

Flexibility and Adaptability

If industrial robots are to serve the company in MRO applications, they need the capacity to adapt to changing conditions to be successful. Usually, robots can adjust their operations based on different inputs and scenarios, like changes in production levels or customer demand. To adapt, they should respond quickly to new tasks or instructions. Eventually, systems gain benefits like increasing productivity, reduced errors, and maintenance concerns.

Predictive Maintenance

Predictive maintenance is another expected challenge for industrial robot integration. This involves using sensors and other technologies to predict potential problems before they occur. With these predictions, companies can schedule preventive measures before any damage occurs or production levels are affected. So, implementing predictive maintenance strategies will reduce downtime and improve productivity.

Overcoming Integration Challenges with Robotic Simulation Software

Robotic simulation software can help businesses overcome the challenges of integrating industrial robots into MRO applications. By simulating a robot’s environment and tasks, companies can ensure that the robot is programmed to operate correctly and can work for the client. This type of software can also help reduce human errors through improved programming accuracy and faster testing of robot controllers.

In the case of MRO applications, robotic simulation software such as RoboDK can help to improve accuracy and optimize processes. Furthermore, proper robot modeling and simulation can lower the chances of errors when machining, repairing, tooling, and operating on delicate materials, such as those used in laser welding. In laser welding applications where different software must coexist, robotic simulation effectively checks that the operation will function as intended.

Do you have an MRO integration challenge? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum. Also, check out our extensive video collection and subscribe to the RoboDK YouTube Channel.