Not sure what you need to know about robotic palletizing?

There are many great reasons for picking robotics over the alternatives. However, there are some fundamentals that are important to learn before you start using robot palletizing.

Here is an essential guide to robotic palletizing; What is it and how do you program a palletizing robot?

If you have a medium to high-volume packing process, a palletizing step is probably an integral part of it. Maybe you’re currently performing the step manually or maybe you’re already using some form of automation.

You’ve almost certainly considered using robots.

There are several options for autonomous palletizing. However, robotics is quickly becoming an extremely popular option thanks to its flexibility and its ability to handle mixed-case pallets. The market for robot palletizers is growing steadily, largely thanks to the need to replace labor.

Maybe you already know the basics of robotic palletizing. Even so, it can help to go over the fundamentals. That way, you can make a better appraisal of your requirements for a robotic palletizer.

What is Robotic Palletizing

Robotic palletizing is the practice of using an industrial robot to place and stack goods onto a pallet for transportation. Many robots can be used for palletizing and the most common approach is to use dedicated palletizing robots for quick transportation of heavy, bulky items.

The major difference between robotic palletizing and other forms of automated palletizing is that a robot gives you much more control over the way that the arrangement of the pallet.

With the right programming solution, you can easily create mixed pallets with objects of different shapes and sizes. It is also easy to reprogram the robot for completely new product lines; a change that would require months of mechanical design with conventional palletizing machines.

Does Palletizing Always = Big and Heavy?

When we think of palletizing, we often think of huge robots moving large and heavy boxes onto pallets piled high with products. This might mistakenly lead you to think that palletizing is only ever suitable for big and heavy objects.

In reality, palletizing can be done on any scale. It is really just a more advanced version of pick and place.

The key detail that distinguishes a palletizing task from basic pick and place is the fact that the put-down location always changes (or the pick-up location for depalletizing tasks). Objects are laid down in a grid on top of the pallet, so each location is immediately next to the previous one.

And just because we talk about arranging items on a “pallet” doesn’t mean they always have to be large, wooden pallets. You can do a palletizing task onto almost any surface.

What Type of Robots Can Be Used for Palletizing?

With this in mind, you can use almost any robotic arm for palletizing. As long as the robot can pick up objects and put them down elsewhere, it can probably handle palletizing.

However, some robots are more suited to palletizing than others. The robot you choose will depend on the nature of your chosen palletizing task, what type of objects the robot will handle, and what level of performance you require.

Here are some common types of robots:

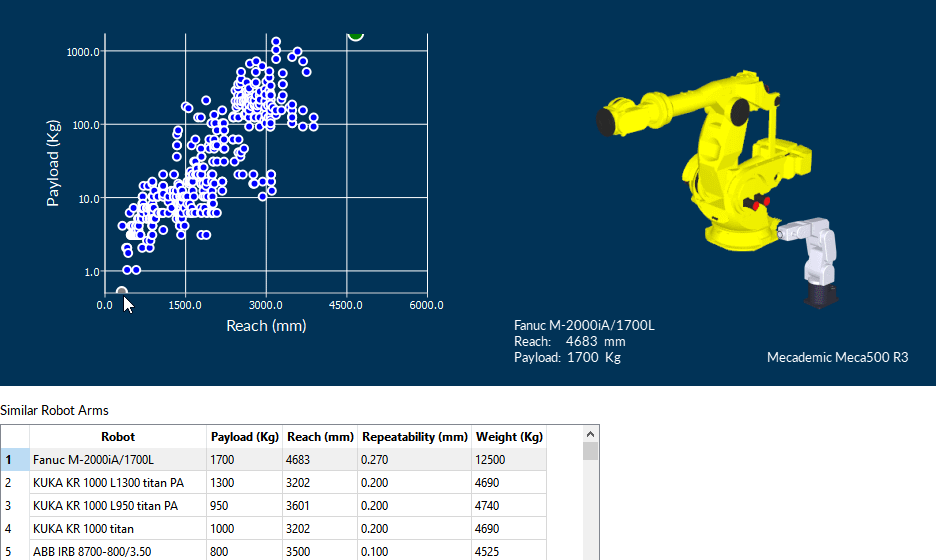

- Palletizing Robots — Probably the best option for most situations. These are big robots with a large payload capacity and long reach. They usually use axis coupling, a design choice that allows for the actuators of the robot’s elbow to be fixed into its base, increasing the speed and payload capacity.

- 6-Axis Industrial Robots — Good for their flexibility, these are usable for many tasks within the workspace, including palletizing. They come in a vast range of sizes, which means that you should be able to find a suitable one. The biggest robots currently on the market (with the largest payloads) are 6-axis robots and are necessary for heavy objects.

- Collaborative Robots — Best suited to low-payload tasks that do not require speed. Cobots have an advantage where they can operate without safety fencing. They are commonly used for small, low-performance palletizing.

- Delta Robots — Usually used for high-speed pick and place, it is also possible to use Delta robots for detailed palletizing tasks. This is quite rare but it is possible.

- SCARA Robots — Most SCARA robots are used for light, detailed assembly tasks which means it could be suited to smaller palletizing tasks. However, there are also some specialist SCARA robots for heavy-duty palletizing.

- Gantry Robots — These can have an even bigger payload than all other types of robot, with the ability to palletize almost anything that can be lifted by an overhead crane.

You can find examples of all of these types of robot in our Robot Library.

How to Program a Palletizing Robot Quickly and Easily

Whatever type of robot you have, programming a palletizing task can be easy if you use a good robot programming software.

You might be tempted to hard-code each point in the program manually. After all, this is the traditional way to create a robot program. However, this would be a mistake. It would make your code hard to update and reduce the benefit of using robotic palletizing at all.

Ideally, you want to use a robot programming software that can cycle through the various palletizing locations automatically. You can simply tell the software the dimensions and the properties of the palletizing pattern (e.g. length, width, repetition properties). It then automatically calculates the exact robot locations.

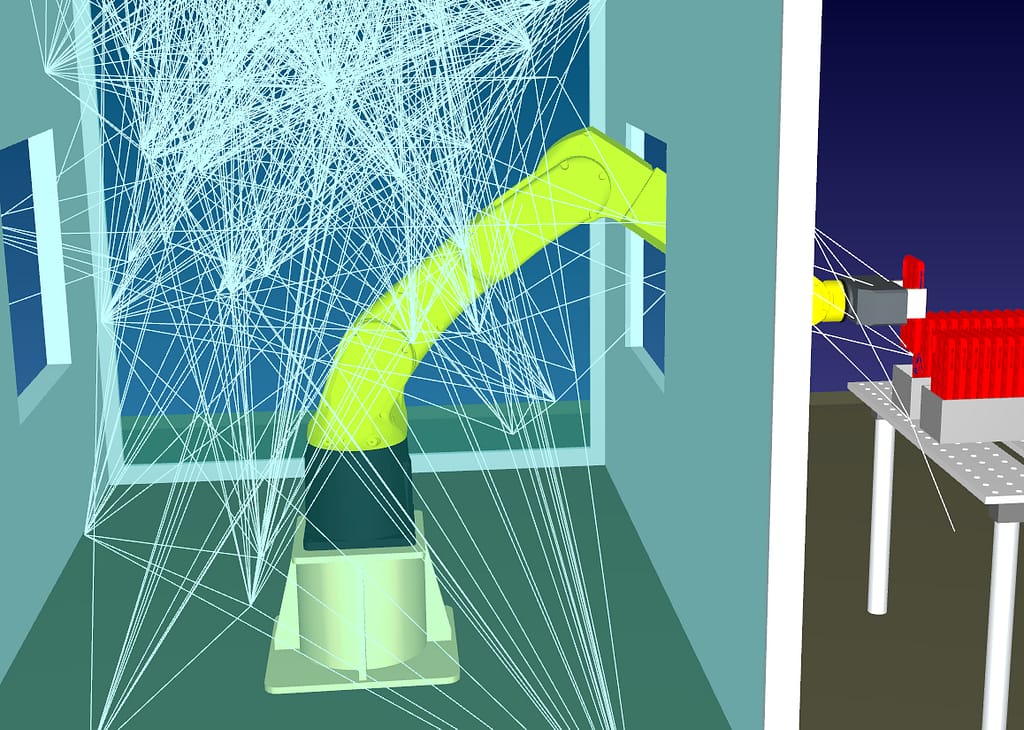

With RoboDK, palletizing is now easier than ever, no matter which robot you are using. This is made possible thanks to our new palletizing plugin, which is available with the latest version.

This new feature is accessible through the Palletizing Panel. It allows you to set the basic properties of the palletizing pattern (approach height, X and Y repeat, etc). Moreover, it also accepts more complex properties such as alternating orientation between layers. This feature is often required to ensure the stability of palletized products.

What questions do you have about robotic palletizing? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.