Precision and flexibility are not always easy to achieve for inspection applications, which often rely on manual effort or static automation. The Intelligent Sorting Framework project from ARENA2036 aims to confront this challenge head on with RoboDK.

Industry 4.0 has been developing for some years, bringing smart manufacturing to companies through technologies like artificial intelligence (AI) and the Internet of Things (IoT). However, for small and medium-sized companies, the inefficiencies and high operational costs for inspection can be a barrier to scaling.

With the Intelligent Sorting Framework, the team at ARENA2036 is not just addressing technical needs. It is reshaping how manufacturers can scale and adapt inspection workflows efficiently.

Here’s how they achieved this with the help of RoboDK.

Introducing… ARENA2036

ARENA2036 (Active Research Environment for the Next Generation of Automobiles) is Europe’s leading research campus for mobility and production innovation. Based in Stuttgart, Germany, this platform unites researchers, industry partners, and startups to develop solutions for smart manufacturing and digitization.

By fostering collaborative partnerships, the team at ARENA2036 campus aims to redefine global manufacturing standards using a variety of advanced technologies.

The Intelligent Sorting Framework and AI Matters Initiative

This project, The Intelligent Sorting Framework, aims to enhance both the accuracy and the scalability of inspection applications through the use of robotics and artificial intelligence.

This falls within the wider AI Matters Initiative — in partnership with the European Commission — which is dedicated to integrating trustworthy, human-centric AI into real-world industrial environments.

The Vision Behind the Intelligent Sorting Framework

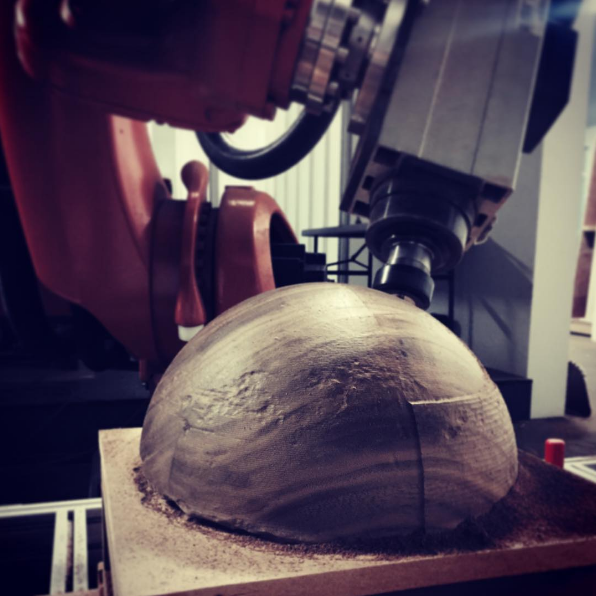

Industries like automotive and aerospace rely on lightweight industrial components that require tight tolerances — such as gearboxes, battery casings, and dome-shaped geometries — where even minute defects can significantly degrade performance.

Traditional inspection tends to rely on manual evaluations, fixed automation, or both. These often lead to inefficient inspection processes that are difficult to scale.

The Intelligent Sorting Framework project addresses these critical challenges by introducing a dynamic, scalable solution. The aim is not just to enhance inspection accuracy but also to reduce downtime, minimize costs, and boost throughput. These values resonate deeply with many small and medium enterprises (SMEs), which are the target of the project.

Dr. Ing Muhammad Saeed, the Research Coordinator, said:

“Through the AI Matters initiative at ARENA2036, we aim to make intelligent AI and robotics accessible to SMEs. RoboDK enabled us to develop a fully simulated intelligent sorting framework, reducing cost, complexity, and time-to-deployment.”

With a simulation-based development — supported by RoboDK — the framework eliminates costly trial-and-error development on physical systems, offering a level of adaptability that aligns well with the core objectives of Industry 4.0.

The System Architecture

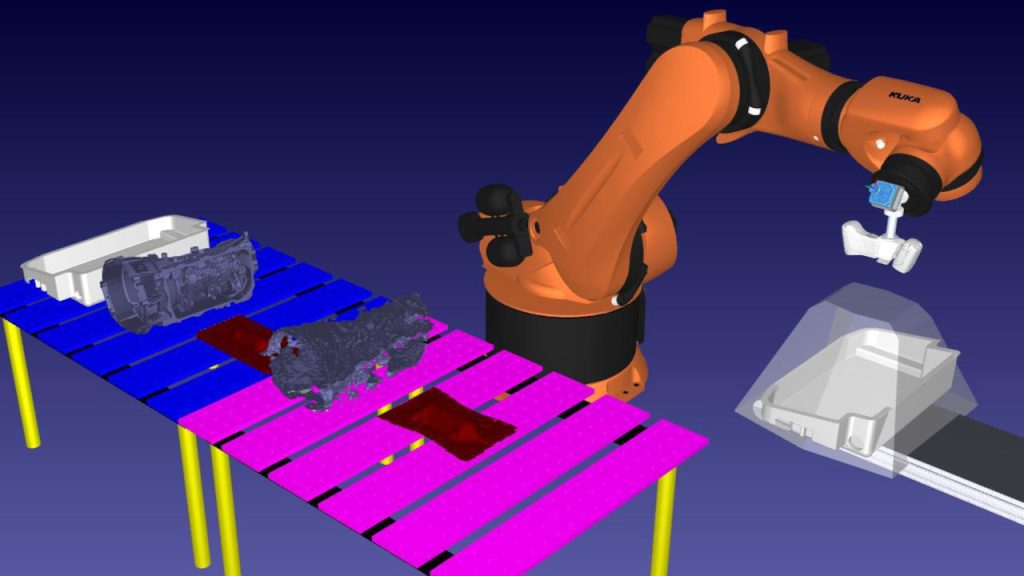

Through a robust combination of robotic hardware, software, and AI-driven algorithms, the team’s automated solution can automate inspection and sorting processes across various manufacturing environments.

Dr Saeed said:

“The system, based around RoboDK, is a powerful example of how digital tools can empower even small teams to prototype and validate industrial solutions quickly and affordably”

Here are the principal components of the solution the team at ARENA 2036 developed:

Hardware Components

The core hardware for this project is based around a standard industrial manipulator and task-specific peripherals.

These hardware components included:

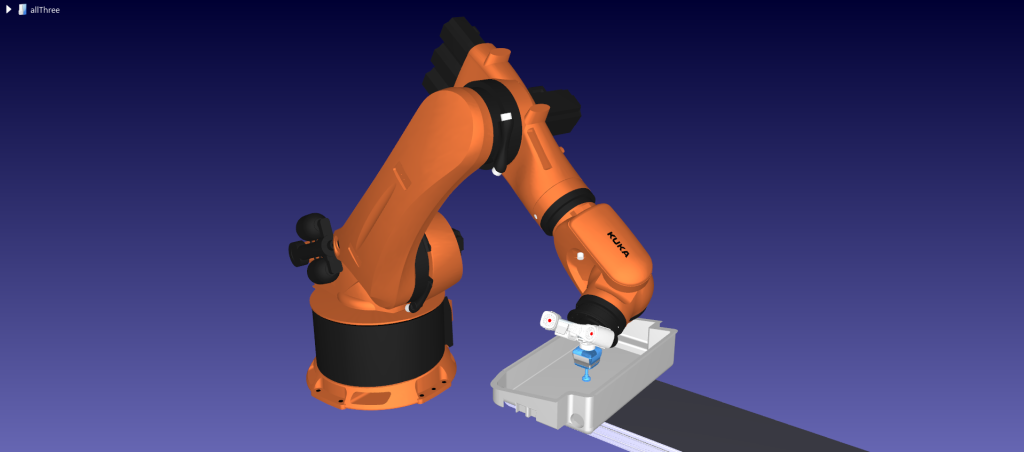

- KUKA KR360 Robot — This high-payload, six-axis robotic arm is one of the most powerful and efficient robots on the market. Several variants of the model are available in the RoboDK Library.

- FARO LeapST 3D Scanner — Mounted directly on the robot arm, this 3D scanner captures detailed snapshots of part geometries that are fed into the vision algorithms.

- VGC10 Vacuum Gripper — A versatile option for pick-and-place. This small electric vacuum gripper is ideal for tight spaces and those applications requiring high customization.

- Dual Quick Changer — The quick changer allows seamless transition between scanning and pick-and-place operations during the sorting process.

Software and Simulation

The project used a software workflow based around some advanced algorithms brought together by RoboDK.

The software components of the project included:

- RoboDK Robot Simulator — With its extensive, powerful feature set, RoboDK’s leading robot simulator provided a firm foundation for the project.

- 2D Camera Simulation and Vision Pipeline — The team developed a sophisticated vision workflow, based around RoboDK’s Cam2D_Snapshot feature to produce high-quality simulated images.

- Dynamic Path Selection — Using Python-coded logic, the solution dynamically adjusts the robot’s movement paths based on the classification of each part.

- Collision and Reachability Checking — RoboDK’s collision mapping tool ensured safe and efficient motion planning. While reachability maps guaranteed unobstructed access to critical inspection points.

AI Integration

The framework employs advanced vision-based classification powered by the ORB (Oriented FAST and Rotated BRIEF) algorithm from the powerful OpenCV computer vision library.

By matching key features from scanned images with pre-defined reference geometries, the system achieves reliable and transparent defect detection. The algorithm dynamically guides the robot to sort parts into bins based on real-time evaluations.

Future Plans

While the Intelligent Sorting Framework has already delivered valuable results, its roadmap for future advancements promises even greater capabilities.

The researchers plan to extend the solution by exploring deep learning, reinforcement learning, 6 DoF pose estimation, point cloud analysis, and dataset expansion. We look forward to seeing what they add in future versions!

Shaping the Future of Intelligent Manufacturing

Developed under visionary programs like ARENA2036 and AI Matters, the Intelligent Sorting Framework exemplifies what is achievable when advanced robotics, AI, and simulation converge.

With RoboDK as the central simulation tool, the team has delivered a scalable and efficient solution that addresses the critical needs of modern inspection workflows. This project not only solves some very relevant inspection bottlenecks. But also paves the way for new advancements in Industry 4.0-compatible production systems.

What bottlenecks do you experience in your inspection process? Join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.. Also, check out our extensive video collection and subscribe to the RoboDK YouTube Channel