In 2025, manufacturers have a lot to contend with. Ongoing labor gaps are making it more difficult than ever for manufacturers to deliver products in full and on time. For many, saying “yes” to new business simply isn’t feasible.

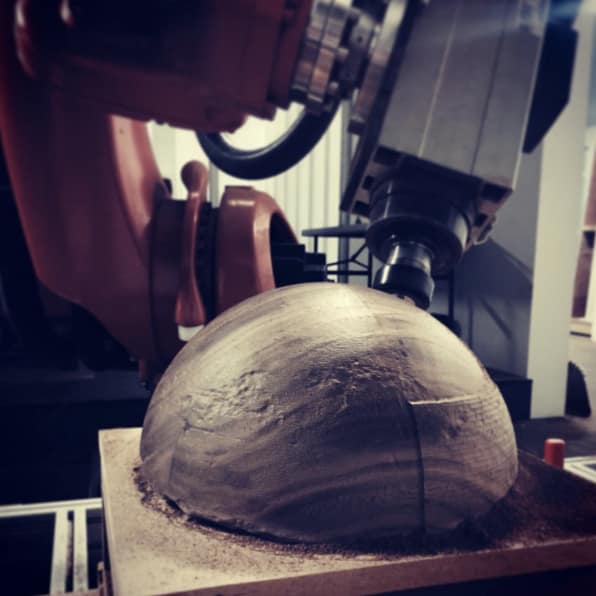

One solution many manufacturers are turning to increase capacity is automation. End-of-line automation allows teams to transition from ergonomically taxing work to more creative, high-value tasks such as project management, maintenance, and process optimization. Automation doesn’t just fill labor gaps; it helps manufacturers increase capacity, reduce errors, and improve consistency across the production floor.

But even automation needs its power boost, especially when manufacturers are juggling multiple SKU changes and complex production recipes. That’s where Formic and RoboDK come in.

Unlocking Speed, Accuracy, and Flexibility with RoboDK

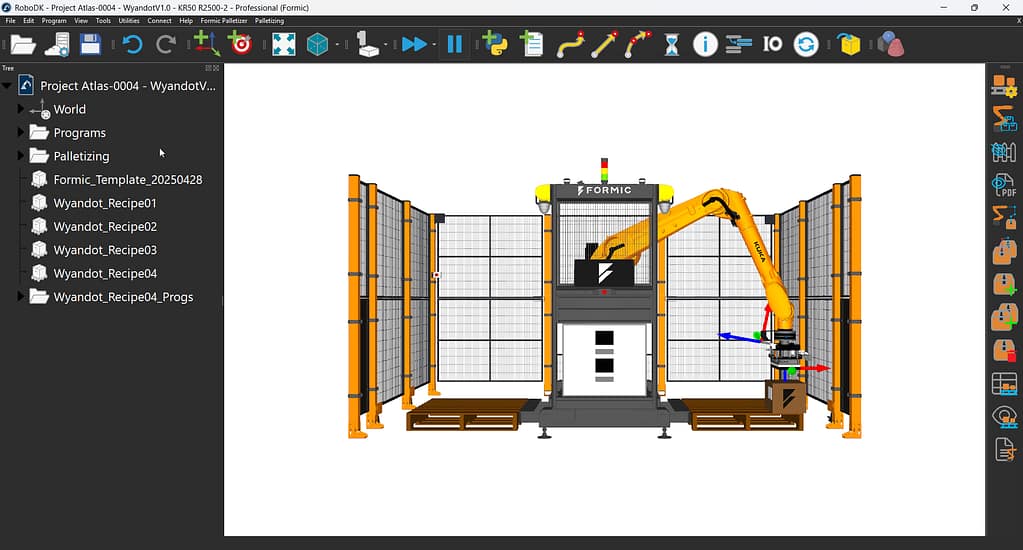

By integrating RoboDK into our systems, we make it faster and easier to program new recipes, test them in a simulated environment, and ensure frictionless transitions on the production floor. Pre-engineering and simulation capabilities let us validate setups before deployment, saving time, minimizing errors, and helping manufacturers scale without disruption.

Real-World Results: Wyandot Snacks

Ohio-based Wyandot Snacks provides a clear example of how this works in practice. With dozens of SKUs and frequent recipe changes, keeping up with demand was a challenge. Using RoboDK’s solution, Formic was able to quickly program and test new recipes, reducing downtime and ensuring Wyandot’s lines kept running efficiently. The result is more products shipped on time, less stress on employees, and greater flexibility to say “yes” to more business.

For Formic, RoboDK isn’t just a tool for our customers: it’s a force multiplier. By leveraging simulation-driven pre-engineering, our engineers can design, test, and optimize new automation setups before ever touching the factory floor. This enables faster deployment across multiple sites, reduces trial-and-error during installation, and ensures consistent performance across every system we deliver.

Expanding Access to Automation Skills

Formic and RoboDK are both also committed to helping manufacturers learn and grow alongside automation. RoboDK Academy, just launched this year, is a free, self-paced online training platform designed to bridge the global robotics skills gap by providing accessible, software-driven education in industrial robot programming.

For manufacturers looking for a proven roadmap, Formic’s new 200-page book, Automate Now, complements this education by laying out everything you need to know to successfully implement automation and achieve long-term results. From building your automation roadmap to getting your team onboard, Automate Now is the ultimate guide to automating with success.

Together, Formic and RoboDK are helping manufacturers produce more, faster, and smarter: making automation not just a tool, but a competitive advantage.