In a fast-changing manufacturing business, operations come and go. What if your robot’s job becomes obsolete? Here’s the right way to repurpose it.

In the past, a robot’s job was “for life.” The requirements of mass production meant that the robot would most likely be doing the same operation forever. Even when you changed to a different product line, you would just tweak the robot’s program slightly and it would continue with the same operation as it had done before.

With high-mix, low-volume or small-batch manufacturing, this is not necessarily the case any more.

Sure, you’ll try to keep the robot doing the same operation as much as possible. But, it’s very possible the robot’s operation could become unnecessary.

People worry that robots will make their jobs obsolete.

Should you worry if your robot “loses its job”?

Not if you can repurpose it.

Can a Robot Be Easily Retasked?

The quick answer to this question is: Yes!

Robots can be easily repurposed to new tasks. In fact, that’s one of the major strengths of robots as a manufacturing technology — they are extremely flexible.

Even if you have kitted-out your robot cell with a lot of custom-built extras, the underlying robot is still the same one that you purchased in the first place. As a result, it has the same inherent flexibility that it always did.

Of course, some robots are more repurposable than others.

Palletizing robots, for example, are only really suited to palletizing tasks (though it may be possible to repurpose them for machining)

Delta robots are also mostly suited to pick-and-place tasks.

Even so, whatever robot you have, it’s very possible that you can retask it to a different operation within your production.

If you have a 6 Degree of Freedom (DoF) industrial robot, your possibilities are practically endless.

Why You Might Want to Repurpose a Robot

Imagine you’ve got a 6-DoF robot operating in your production line. It has been doing its task — spot welding steel bars together into a rectangular grid — for almost a year.

One day, you find a new supplier who is able to offer bars pre-welded to the shape and dimensions that you need. What’s more, they are able to offer the pieces at a much cheaper cost than you were able to achieve previously, taking into account material costs, power to the robot, and wastage.

In an ideal scenario, you’d be able to move the robot to a new spot welding task. This would be very quick to reprogram, depending on what method you use to program your robot.

But, what if you don’t have any other welding tasks?

Perhaps you originally brought in the robot because the only trained welder on your team only had the grid-welding task and occasional one-off welding tasks. Now the grid-welding task is gone, their time is much better spent on other operations. The grids were the only real candidate for robotic welding.

Your robot sits silent on the workshop floor for a couple of months.

It becomes obvious that it is just gathering dust.

Once you have made sure that there are no spot welding tasks for the robot to do, it’s time to think about retasking the robot to a new operation.

This type of situation can happen to any business with any manufacturing operation.

6 Steps to Repurpose an Industrial Robot the Right Way

Here are the six steps to take when you have decided to retask your jobless robot:

1. Identify That the Old Task is Really Unnecessary

As mentioned above, first make sure that the robot’s old task is truly unnecessary. Even the quickest robots to deploy take time (weeks or months usually).

You don’t want to spend hours of your valuable time only to find that you did need that old robotic welding cell after all.

2. Identify Potential New Tasks

Make a list of all the potential tasks that could be good candidates for automation.

Robots are great for a variety of different operations, including painting, picking, and 3D printing.

Then, identify the top task or tasks that you want to try to automate.

3. Make a Simulation

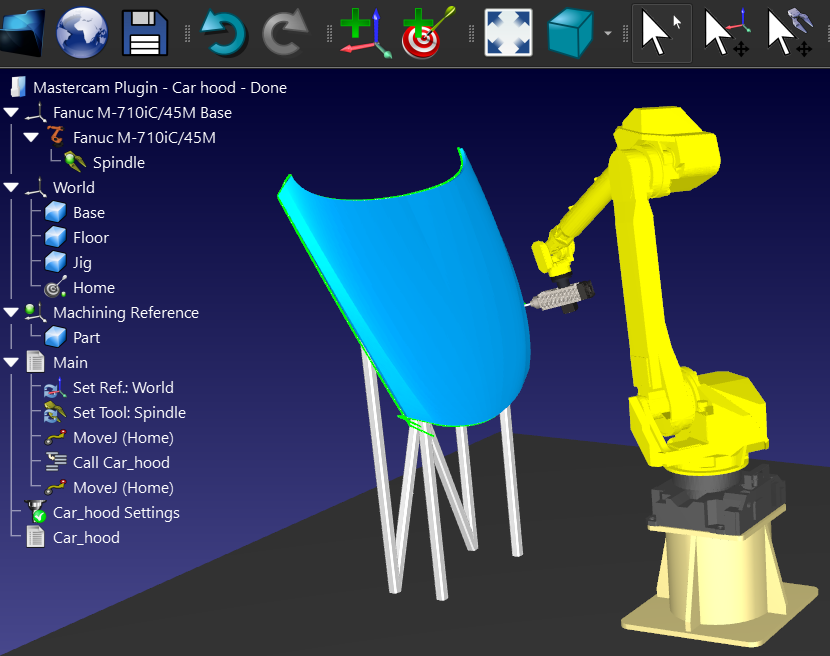

Before you think about touching the physical robot, use a robot simulator to make a virtual mock-up of the new task in software.

Simulation is much quicker than setting up a physical mock-up and allows you to identify if the task is going to be possible with the robot before you even get out your spanner.

4. Try the Robot in the New Simulated Task

Load your robot model into the simulator and try it out with your chosen task.

At this point, you’re not looking to optimize your application as much as possible. You are just getting an idea of whether or not the task will suit your existing robot.

5. Assess if the Robot is Suitable

Decide if the robot is going to be able to achieve the new task.

If not, try the task with some different robot models to see if it really is your robot that is the problem or if you need to improve your simulation. If the robot still doesn’t match, try it on one of the other tasks on your list.

When the robot is suitable for your chosen task, you can move on and actually deploy it.

6. Deploy the New Task

Now it’s time to complete the design of your robot cell, optimize it as much as necessary, and get your spanner out to move the robot.

This stage is what will take the time, but you have already done a lot of the hardest work in designing and developing the program for the robot.

If your robot simulator has offline programming capability, you can use it to program the robot directly without having to do any more programming.

What to Do If the Robot Doesn’t Suit Any Task

You might find that the robot is unsuitable for any task in your business. In this case, you have two options:

- Store it — You could decide to “wait it out” and see if a suitable task comes up later. Put an automatic reminder in your calendar for a few months from now and reassess the situation then.

- Sell it — It is possible to sell used robots and recoup some of your initial purchase cost, which you can use towards buying a more suitable robot. Some robot brands (ABB and KUKA for example) will buy back your robot from you and there are also specialist robot resellers.

An added benefit of this process is that you have probably identified some more tasks in your business which you could automate, whether with your old robot or another one!

Do you have a “jobless” robot? What will you do with it? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram or in the RoboDK Forum.