Surface finishing with a robot — it’s an application you might not have considered before.

You might wonder: Is there a good end effector to perform sanding or polishing with a robot? And how easy is it to program a robot with such an end effector?

But, the team at Kane Robotics found a way to easily integrate their robot and new orbital sanding end effector with RoboDK.

Let’s see how they did it!

Sanding and polishing are the types of task that are traditionally difficult to automate. In the past, you either had to invest big in an automatic sanding machine — the type that will take up half of the space in your workshop and cost a small fortune — or you’d have to do the task manually.

The problem with doing surface finishing manually is that it is time-consuming, physically hard work, and provides an inconsistent quality. Sounds like the perfect task for a robot!

In recent years, surface finishing with an industrial robot has now become a viable option. By adding a force sensor onto the robot’s end effector, you can use force control to provide consistent surface finishing with an orbital sanding tool.

As a result, industrial robots can now be used for surface finishing tasks that require a high degree of consistency, such as propeller blade polishing for aircraft…

… which is exactly what the team has done at Kane Robotics.

Introducing… Kane Robotics

Kane Robotics is an automation integration company based in California, USA. They primarily serve the aviation and aerospace sector and provide automation solutions to high-mix/low-production manufacturers.

They describe their company mission as: “to free up the skilled aerospace workforce from time-consuming, repetitive manufacturing tasks through the use of innovative, low-cost, flexible automation solutions.”

In particular, they help aerospace manufacturers with applications such as grinding, sanding, finishing, epoxy dispensing, drilling, and machine tending.

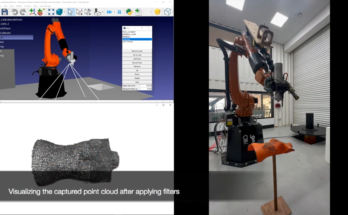

The company’s project involved polishing the propeller blade for an aircraft.

The Project: Propeller Blade Polishing

Propeller blades are a delicate and impressive piece of engineering. They are the primary means by which an airplane achieves its thrust in the air. Any mistake in their manufacturing process could lead to an inefficiency in the aircraft’s propulsion or, in the worst cases, disaster.

The polishing stage is vital in airplane manufacturing. Bad surface finishing can cause unnecessary drag in the air and cause the plane to use more fuel than is necessary.

Also, the Federal Aviation Administration (FAA) strongly advises against polishing after the propeller has been manufactured as it could damage the delicate protective coatings that are added to the blade’s surface. As a result, the polishing stage during manufacturing is the last moment to get that all-important surface finish.

The team at Kane Robotics set out to produce a polishing application using a robot and a new type of orbital sanding end effector specially designed for robotic surface finishing.

The robot was required to accurately polish the propeller blade using this end effector.

Integrating a Robot-Ready Orbital Sander With RoboDK

Part of the team’s motivation for undergoing this project was to test out a new orbital sanding end effector that they were using.

A common problem with robotic surface finishing is that it requires force control. When we are sanding or polishing by hand, we can precisely control the force applied by the finishing tool. With a robot, the most common way to do this is to add a force sensor and program active compliance into the tool. This can be difficult to program.

The end effector that Kane Robotics used makes it easier to deploy robotic surface finishing than it has been in the past by incorporating compliance into the tool itself.

The Compliant Orbital Sander

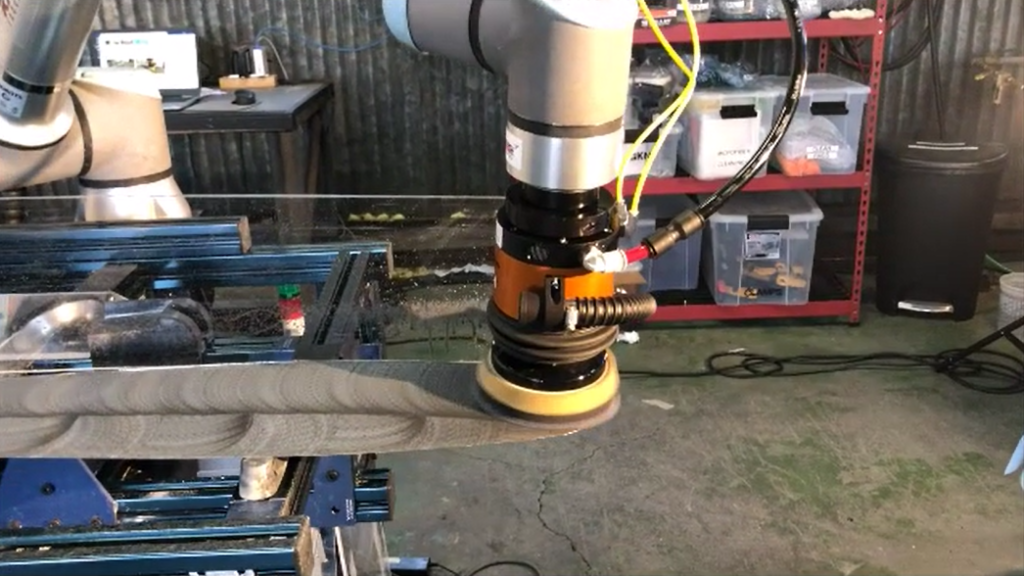

The end effector in question was the AOV-10 Compliant Orbital Sander from ATI, also available as a UR+ component.

This new tool is specially designed to make robotic sanding easy. It incorporates pneumatic compliance into the axis of the orbital sanding tool, giving the robot the ability to react to subtle changes in the surface of the workpiece.

As Alan Hiken, the COO of Kane Robotics, explained:

“The sanding head is a passively compliant head with movement normal to the tool surface. Regulated air is delivered to “extend” and “contract” ports and this controls the “stiffness” of the bellow.

It required us to conduct some trials to determine the required air pressures to deliver the desired performance.”

One of the benefits of using RoboDK with new End of Arm Tooling (EOAT) options like this is that it is very easy to add a new end effector within the software, as we explained in our previous article The 5 Minute Guide to Use Any End Effector with RoboDK.

Their Hardware and Software Setup

The setup used by the team at Kane Robotics was reasonably simple, thanks to the ATI sanding tool.

The main components of their setup were:

- A Universal Robotics collaborative robot.

- The ATI AOV-10 orbital sanding tool.

- A table on which was fixed the propeller blade.

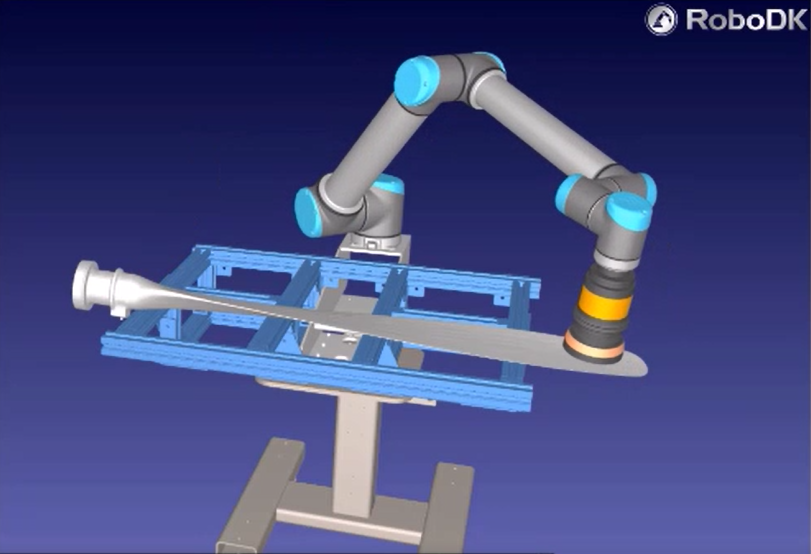

- RoboDK for offline programming.

Without this particular orbital sander, the team may have had to integrate an external force sensor. This would have increased the complexity of both the hardware setup and the programming of the robot.

With RoboDK, their programming was simple.

Why Did Kane Robotics Use RoboDK?

RoboDK allowed the team to get the application up and running quickly and easily.

The programming consisted of only a path planning activity, which can be achieved in RoboDK in only a few steps.

Here’s what COO Alan Hiken said about RoboDK:

“RoboDK is the most competitively priced OLP software in the marketplace and their support of Kane Robotics has been outstanding. [The software is] great value for the low cost [and] new capabilities are being added regularly to make it easier to use with various EOATs.”

When asked why they had used RoboDK he simply said: “If you have the CAD data, why wouldn’t you use it?”

We can hardly argue!

What applications could you achieve with RoboDK? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.